Mastering Metal Polishing: Grit Progression for Aluminum

Imagine standing in your workshop, the soft hum of machinery around you, the air filled with the scent of fresh metal shavings. It’s a place of creation, where raw materials are transformed into shining, polished works of art. You’re holding a piece of aluminum, rough to the touch, yet full of potential. With the right techniques, this unassuming piece can become a mirror-like masterpiece. The secret lies in grit progression—a meticulous, step-by-step process that transforms the mundane into the magnificent.

This journey begins with an idea, a vision of what this aluminum can become. Perhaps it’s a component for a custom motorcycle, a decorative piece for your home, or just a personal project to hone your metalworking skills. Whatever the purpose, the goal is the same: achieving that flawless, reflective finish that makes the metal gleam and catches the eye. But getting there requires more than just elbow grease; it demands an understanding of the art and science of metal polishing.

In today’s fast-paced world, it’s easy to overlook the satisfaction that comes from working with your hands. Yet, there’s something profoundly rewarding about taking the time to sand, buff, and polish metal to perfection. It teaches patience, attention to detail, and the value of craftsmanship. As you stand in your workshop, surrounded by the tools of the trade, you’ll find that each step brings you closer to that moment of triumph when the metal reflects your hard work and dedication.

Quick Summary

Learn the essential steps of grit progression to master metal polishing, focusing on achieving a perfect finish for aluminum.

Understanding the Basics of Grit Progression

Grit progression is the cornerstone of metal polishing, especially when working with aluminum. This technique involves using a series of sandpapers with increasingly finer grit sizes to smooth out the surface of the metal. The goal is to gradually remove scratches and imperfections, preparing the metal for buffing and polishing.

Steps to Follow:

Start with Coarse Grit: Begin with a coarse grit, typically around 80-100. This will help remove any large scratches or surface imperfections. Use a consistent motion to ensure even sanding across the aluminum surface.

Move to Medium Grit: Once the major imperfections are smoothed out, switch to a medium grit, such as 220-320. This step further refines the surface, reducing the depth of scratches from the coarser grit.

Progress to Fine Grit: Continue with a fine grit, usually 400-600. This stage is crucial for preparing the aluminum for the final polishing stages, as it ensures a smooth and even finish.

Finish with Very Fine Grit: For the ultimate mirror-like finish, use very fine grits, such as 1000-2000. Spend ample time on this step to achieve a seamless surface ready for buffing.

Practical Tips:

- Consistency is Key: Always sand in one direction to avoid creating new scratches.

- Use Water: Wet sanding can reduce friction and prevent the sandpaper from clogging.

- Inspect Regularly: Check your progress frequently to ensure you’re not rushing through the stages.

Tools and Materials You Need

Having the right tools and materials is essential for successful metal polishing. Here’s a list to get you started:

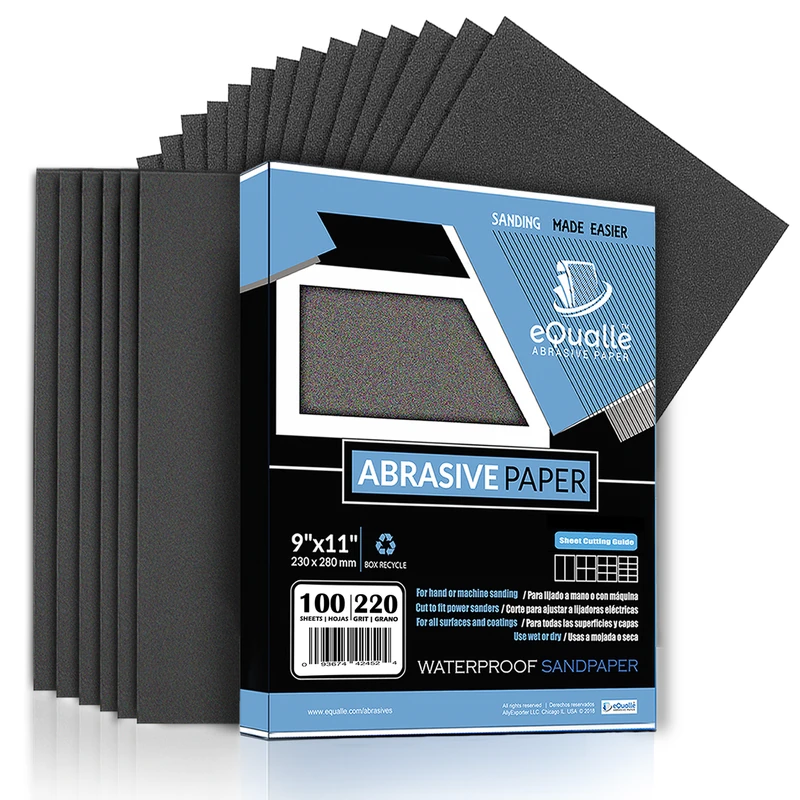

- Sandpapers: A range of grits from coarse to very fine.

- Sanding Block: Ensures even pressure and coverage.

- Water Spray Bottle: For wet sanding.

- Polishing Compound: Used in the final stages to bring out the shine.

- Buffing Wheel: Essential for the last step of metal polishing.

Choosing the Right Sandpaper

When selecting sandpaper, consider the type of aluminum you’re working with and the desired finish. For most hobbyist projects, standard aluminum oxide sandpaper works well. However, for professional or industrial applications, you might need more specialized abrasives.

Maintenance and Care

- Clean Regularly: Keep your tools free from debris to ensure they work efficiently.

- Store Properly: Sandpapers should be stored in a dry place to prevent deterioration.

The Role of Metal Polishing in the Finishing Process

Metal polishing isn’t just about making aluminum shiny—it’s a critical step in the finishing process that enhances durability and aesthetics.

Benefits of Proper Polishing

- Improved Appearance: A polished surface reflects light beautifully, giving your project a professional look.

- Increased Durability: Polishing can help protect the metal from corrosion and wear.

- Enhanced Functionality: In some applications, a smooth finish can reduce friction and improve performance.

According to a guide on Empire Abrasives, grit progression is key to achieving these benefits, as it lays the groundwork for effective polishing.

Common Applications

- Automotive Parts: Polished aluminum is often used in car parts for its aesthetic appeal and resistance to corrosion.

- Home Decor: From light fixtures to furniture accents, polished metal adds a touch of elegance.

- Industrial Equipment: In machinery, polished surfaces can reduce friction and increase efficiency.

Mastering the Final Buffing and Polishing Stages

After completing the grit progression, it’s time to move on to buffing and polishing. This is where the aluminum truly begins to shine.

Buffing Techniques

Apply Polishing Compound: Use a small amount of polishing compound on a buffing wheel. Spread it evenly across the aluminum surface using gentle, circular motions.

Buffing Wheel Speed: Ensure the buffing wheel is set to the correct speed—too fast can generate heat and damage the metal, while too slow may not be effective.

Consistent Pressure: Apply even pressure to avoid creating uneven patches or burns.

Polishing Tips

- Use a Soft Cloth: After buffing, use a microfiber cloth to wipe away any excess compound and enhance the shine.

- Inspect Your Work: Look for any areas that may need additional attention and repeat buffing if necessary.

Maintaining Your Polished Aluminum

Once you’ve achieved that perfect finish, maintaining it is crucial to ensure longevity. Here’s how to keep your aluminum looking its best:

- Regular Cleaning: Use a gentle cleaner and soft cloth to remove dirt and fingerprints.

- Protective Coatings: Consider applying a clear coat or wax to protect the surface from oxidation and scratches.

- Avoid Harsh Chemicals: Steer clear of abrasive cleaners that can dull the finish.

Frequently Asked Questions (FAQ)

Q: What is grit progression in metal polishing?

A: Grit progression involves using sandpapers with increasingly finer grits to smooth and prepare metal for buffing and polishing.

Q: How important is grit progression for aluminum?

A: It’s crucial as it sets the foundation for a flawless finish and ensures the surface is ready for the final polishing stages.

Q: Can I skip any grit stages?

A: Skipping stages can result in visible scratches and an uneven finish, so it’s best to follow each step carefully.

Q: What tools are essential for metal polishing?

A: You’ll need a variety of sandpapers, a sanding block, a buffing wheel, and polishing compounds.

Q: How do I maintain a polished aluminum surface?

A: Regular cleaning and protective coatings can help maintain the finish and prevent damage.