Mastering Wood Sanding: Avoiding Swirl Marks

Woodworking is more than just a hobby—it’s a passion. Picture this: the soft glow of morning light streaming through your workshop window, the smell of freshly cut wood filling the air, and the satisfying hum of your sander as you work on your latest project. You’re sanding a beautiful oak table, envisioning the perfect smooth finish that will make your craftsmanship shine. But as you wipe away the dust, you notice the dreaded swirl marks marring the surface. It’s a common frustration among woodworkers, both novice and seasoned, but it doesn’t have to be your reality.

Swirl marks are the nemesis of any woodworker aiming for a pristine finish. They can turn a masterpiece into a mess, leaving you with more work or, worse, a compromised project. Understanding the art of wood sanding is crucial to sidestepping this pitfall and achieving that smooth, professional look. Whether you’re restoring a cherished piece of furniture or crafting something new, mastering the techniques to avoid swirl marks can elevate your work from good to exceptional.

Quick Summary: This guide provides essential techniques and tips on wood sanding to prevent swirl marks, ensuring a flawless finish for your woodworking projects.

Understanding the Basics of Wood Sanding

Before diving into techniques to prevent swirl marks, it’s essential to grasp the basics of wood sanding. Sanding is a process that smoothens the wood surface, prepares it for finishing, and enhances its aesthetic appeal. The key lies in the choice of sandpaper, the type of sander used, and the technique applied.

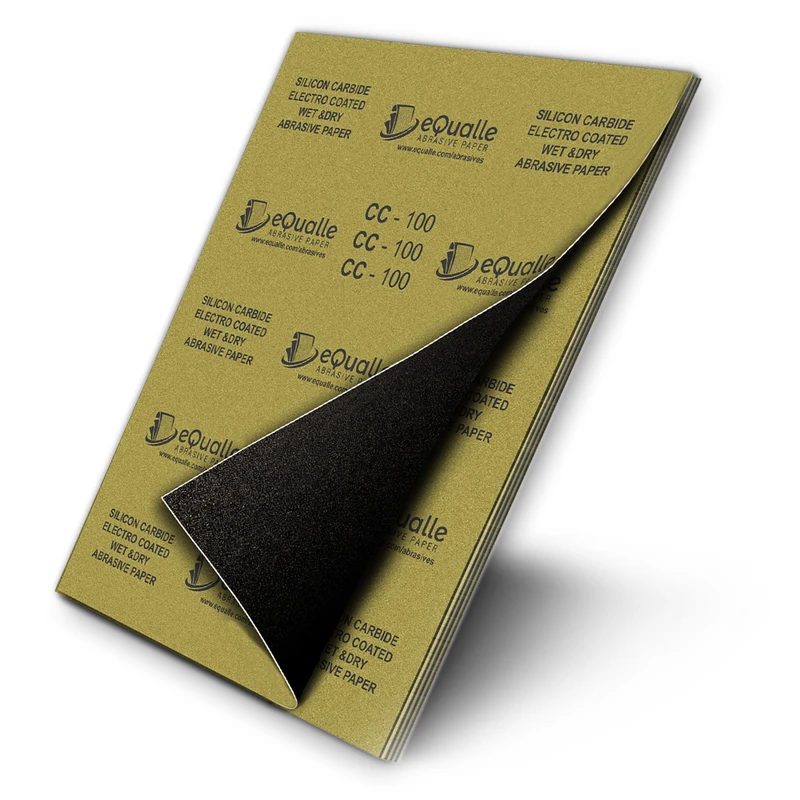

Choosing the Right Sandpaper

Selecting the right sandpaper is your first line of defense against swirl marks. Sandpaper comes in various grits, from coarse to fine. Start with a coarser grit to remove major imperfections and switch to finer grits to smooth out the surface. Here’s a simple guide:

- Coarse Grit (40-60): For removing old finishes or heavy sanding.

- Medium Grit (80-120): Ideal for smoothing surfaces and preliminary finishing.

- Fine Grit (150-180): For final surface preparation before applying finish.

- Extra Fine Grit (220 and above): For ultra-smooth finishes and between coats.

Selecting the Right Sander

The choice of sander can greatly impact your sanding results. Orbital and random orbital sanders are popular choices due to their efficiency and ease of use. Random orbital sanders, in particular, are effective in reducing swirl marks as their circular motion combined with a random pattern helps distribute sanding pressure evenly.

Proper Sanding Technique

Technique is everything. Always sand with the grain of the wood to avoid scratches and ensure a smooth finish. Apply even pressure and keep the sander moving to prevent it from digging into the wood.

Techniques to Prevent Swirl Marks in Wood Sanding

Swirl marks often result from improper sanding techniques or equipment misuse. Follow these expert tips to ensure a flawless, swirl-free finish.

Control Your Pressure

One common mistake is applying too much pressure while sanding. Let the sander do the work. Excess pressure can lead to uneven sanding and increase the risk of swirl marks. Maintain a light, consistent touch to allow the sander to glide effortlessly across the wood.

Keep Your Sander Moving

Resting your sander in one place for too long can lead to swirl marks. Keep it moving in a steady, overlapping pattern. This ensures that the sanding is even and prevents any one area from being over-sanded.

Clean Your Surface

Dust and debris can become trapped between the sandpaper and wood, causing scratches and swirl marks. Regularly wipe down the surface with a tack cloth to remove any particles and maintain a clean working environment.

Use Fresh Sandpaper

Worn-out sandpaper loses its grit, causing it to polish rather than sand. This can contribute to swirl marks. Replace sandpaper frequently to ensure effective sanding.

Advanced Tips for Wood Sanding without Swirl Marks

For those seeking to perfect their sanding technique, consider these advanced tips.

Cross-Sanding Technique

Cross-sanding involves sanding across the grain at a 45-degree angle with a coarser grit before finishing with finer grit along the grain. This method helps to reduce the visibility of any potential swirl marks.

Sanding with a Guide Light

Using a guide light can help identify imperfections as you sand. Shine a bright light at a low angle across your workpiece to reveal any remaining scratches or marks that need attention.

Try Wet Sanding

Wet sanding involves using water or a sanding lubricant to keep the sandpaper clean and reduce dust. This technique can be particularly effective for achieving a mirror-like finish without swirl marks.

According to a YouTube video, utilizing the right sanding techniques and equipment is critical in avoiding swirl marks, ensuring a smooth and flawless finish on your woodworking projects.

The Role of Finishing in Sanding

Finishing is the final touch that brings out the beauty of the wood grain and adds protection. Proper finishing can also help mask minor sanding imperfections.

Choosing the Right Finish

Selecting the right finish depends on the intended use of the wood piece. Options include varnish, polyurethane, lacquer, and oil finishes. Each has its characteristics and offers different levels of protection and aesthetic appeal.

Applying Finish Properly

Apply finish in thin, even coats, and allow adequate drying time between applications. Sand lightly between coats with extra fine grit sandpaper to eliminate any imperfections and achieve a smooth surface.

Final Buffing

Once the finish is dry, a final buffing with a soft cloth can enhance the wood’s shine and smoothness, completing your woodworking masterpiece.

Frequently Asked Questions (FAQ)

Q: What causes swirl marks when sanding wood?

A: Swirl marks are often caused by improper sanding techniques, such as using a worn-out sandpaper, applying too much pressure, or not cleaning the surface regularly.

Q: Can I remove swirl marks after they appear?

A: Yes, you can remove swirl marks by re-sanding the affected area with a finer grit sandpaper, ensuring to follow proper sanding techniques.

Q: Is there a specific sander type that reduces swirl marks?

A: Random orbital sanders are effective in reducing swirl marks as their random motion helps distribute sanding evenly.

Q: How often should I change my sandpaper?

A: Change sandpaper as soon as you notice it losing its effectiveness or if it becomes clogged with dust and debris.

Q: What is the best way to finish sanded wood?

A: Apply a suitable finish in thin, even coats, allowing drying time between applications, and sand lightly between coats for the best results.

By mastering these wood sanding techniques and tips, you’re well on your way to achieving swirl-free, stunning finishes on your woodworking projects. Embrace the process, and let your craftsmanship shine with the smooth, flawless surfaces you create.