Concrete Polishing: Metal to Resin Pad Mastery

There’s a moment in every shop or garage when the floor starts to tell your story. Early morning light spills under the door; you flick on the grinder, and the air lifts just a little with the smell of damp concrete and sawdust from yesterday’s build. You set your coffee down, lace up, and eye the slab—dusty in patches, shiny where years of foot traffic have burnished a path to your bench. This is where concrete polishing earns its keep. It’s not just about gloss. It’s about turning a stained, work-weary surface into a durable, cleanable plane that makes every task feel smoother. And like any good build, the finish depends on the foundation: the right tools, the right sequence, and the discipline to switch from metal to resin at the exact right moment.

I’m not here to romanticize grunt work—though I do respect it. I’m here to hand you a method that’s been tested on renovation jobs, new shops, and stubborn garage slabs. Whether you’re the weekend warrior armed with a 20-inch grinder or a seasoned contractor rolling a planetary machine off the trailer, this is the same dance: start with metal bonds to cut, flatten, and reveal; transition to hybrids or resins to refine; lock it in with densifier; and then chase clarity through the last passes. You’ll read the concrete the way a cabinetmaker reads grain, and with a little patience and the right grit progression, you’ll watch it go from chalky to crisp, from dull to a mirror that reflects the fact you did it right.

Because concrete is a living material—soft here, hard there, patched in places and curled by the sun—you need a plan flexible enough to respond. Think of metal bonds as your rough carpentry and resins as your finish work. The art is knowing when to put down the framing gun and pick up the sander. I’ll walk you through that pivot, step by step, with real job-site checkpoints, pressure settings, and the scratch-tracking habits that prevent do-overs. When we’re done, you’ll have a workflow you can repeat, bid, and deliver with confidence.

Quick Summary: Start with metal bonds to level and open the slab, then transition to resin pads for refinement and gloss—timed by scratch removal, densifier placement, and consistent grit jumps.

Assess the slab like a pro

Before any pad touches concrete, read the floor. Slab assessment isn’t busywork—it’s what keeps you from chasing scratches for hours or glazing pads in five minutes. I start with hardness and condition.

Hardness: A simple scratch test does a lot. If a sharp nail leaves a deep score and dusts easily, the slab is soft. If a utility blade skates, it’s hard/trowel-burnished. Soft concrete eats soft-bond metals; hard concrete needs soft-bond metals to cut at all. Write “soft, medium, hard” in your notes—this decides your bond and grit.

Flatness: Sight along the floor under low light and use a 6-foot straightedge. Light under the edge tells you where you’ll be cutting high spots. Crowns, curls near doors, and trowel swirls appear as glaze. Mark problem zones with chalk.

Coatings and contaminants: Taped-down poly squares reveal moisture. Black adhesive, paint, or thin epoxy needs PCDs or coarse metals to strip. Oil stains and curing compounds may require a cleaner or micro-etch before your first cut.

Aggregate exposure goal: Agree on “cream, salt-and-pepper, or full aggregate.” The exposure spec defines your starting grit. Cream means minimal metal cutting; full aggregate means coarse metal and multiple flattening passes.

Repairs: Map cracks, control joints, and patches. Decide if you’re filling with polyurea before or after your mid-grit metals. Remember: repairs sand at different rates and telegraph if not leveled properly.

Then set up your equipment. Fit a tight dust shroud, fresh filter, and a manometer if you have one; airflow is as important as grit. Check your grinder weight—add plates for cutting, remove them when refining. Calibrate your head speed and forward pace in an inconspicuous test area: if a 10-foot run takes 30–45 seconds at your chosen rpm and you’re maintaining a consistent cut, you’re in the right ballpark. Finally, commit to a pass pattern. I like north–south, then east–west, overlapping 30–40% each time. This crosshatch habit will save your finish more than any single pad choice.

Metal bond groundwork, done right

Metal bonds are your sawmill: they cut, level, and set the project up for everything that follows. Choosing the right bond hardness and segment design is step one. Soft-bond metals bite hard slabs; hard-bond metals survive soft slabs without smearing or loading. Mid-bond covers a lot of ground but can slow you down at the extremes. Segment shape matters too—trapezoids and arrows cut differently across edges and surface undulations, while double rounds can ride smoother with fewer gouges.

Grit selection depends on exposure and damage. For coatings or heavy lippage, start at 16/20 or 30/40. For salt-and-pepper exposure or light scratches, 40/60 or 60/80 often works. If the slab is flat and you’re keeping cream, test a 60/80 and only drop down if it skates. Always test a small square and measure your scratch depth. A deep 30/40 scratch takes real time to erase; don’t overcut unless the slab demands it.

Run your metal bonds with enough weight to engage the surface—too light, and you’ll skate; too heavy, and you’ll plow. For most mid-size planetary grinders, a modest weight kit and head speed around 450–600 rpm is a stable starting point; slow forward motion, steady overlap. If you’re running single-head or smaller machines, reduce rpm to avoid chatter and adjust your pace—let the diamonds do the work. Keep dust extraction dialed in: if you see fines collecting behind the head, you’re either moving too fast or your filter is loading.

When the floor looks even, your work is only half done. The metal bond stage ends when the scratch pattern is uniform across the entire field. That means no islands of untouched cream, no stripes from inconsistent overlap, and no stray 30/40 scratches after your 60/80 pass. Finish with a 120 metal if you want an easier transition to resins; it tightens the scratch profile and reduces risk of ghosts.

Actionable tips for metal bond success:

- If your diamonds smear or paint the slab, the bond is too soft for that concrete; switch to a harder bond.

- Add a gentle water mist for hard, glossy slabs to reduce glazing—but manage slurry and vacuum often.

- Sharp new metals can cut aggressively; break them in on a sacrificial pass in a doorway or scrap slab.

- Track your runtime per set of segments; when cutting slows and heat rises, rotate or flip segments to even wear.

Grit sequence for concrete polishing clarity

A great polish is a tidy story told in grit jumps. Each pass should erase the previous scratch pattern and replace it with a finer one—no mysteries, no hoping gloss will hide sins. A reliable sequence for broad slab work looks like this: 30/40 metal → 60/80 metal → 120 metal → transitional 50/70 hybrid (optional) → 100 resin → 200 resin → densifier → 400 resin → 800 resin → 1500 resin → 3000 resin (as needed for spec). The exact list flexes with slab goals, but the principle doesn’t: don’t skip more than one logical step, and don’t move on until scratches are truly gone.

After your 60/80 and 120 metals, examine with a raking light. On softer slabs, you can sometimes jump from 80 metal to 100 resin if you add a transitional hybrid step—those are half metal, half resin, designed to bridge the cut. Hard slabs with tight cream often need the 120 metal to prevent ghost scratches from showing at 400 resin and beyond. According to a article, the right diamond progression is the backbone of a consistent, high-clarity finish; it saves time by preventing rework at the top grits where removal rates are low.

Timing your densifier is a big lever. If you’re targeting moderate exposure and need to harden open paste, apply densifier after the 200 resin. That locks the fines and supports crisp refinement at 400 and above. On soft or chalky slabs, consider an earlier densify—after 80 or 120 metal—to stiffen the surface before you start refining. Choose lithium or sodium/potassium silicate based on your experience and product specs; the main thing is even, thin application, and enough dwell to react. Avoid pooling—hardeners carry fines that can streak if left to dry unevenly.

Never forget edges and joints in your sequence. Match their grits to the field. If you end your metals at 120 on the main machine, bring edge tools to the same point—or a touch finer—before the field goes to 100 resin. Keep a scratch log: “Field 120 metal complete, all edges 150 metal” is the kind of note that prevents one rogue band of metal scratches from surfacing at 800 resin when it’s too late.

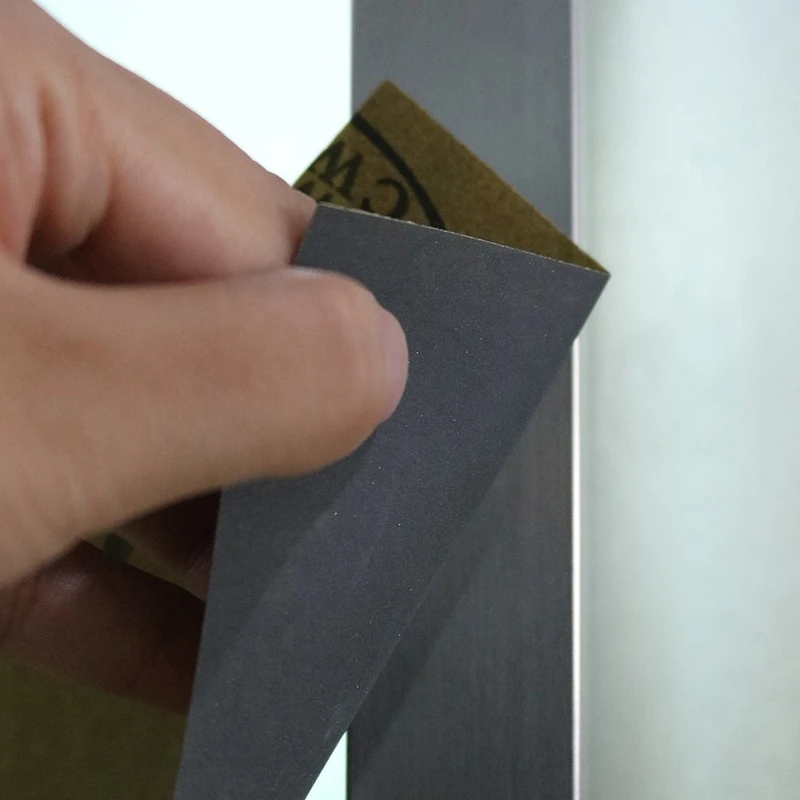

Switching to resin without surprises

The pivot from metal to resin pads is where a job gets made or broken. Resins don’t erase deep scratches; they refine. The signal to switch is a uniform, tight metal scratch pattern, the exposure you agreed on, and no glaze or patch mismatch that would telegraph through. If in doubt, tape off a 3-by-3-foot test square. Run your chosen first resin (often 100) with your normal overlap. Wipe the dust and flood with raking light. If you see straight-line, deep grooves, you’re early; drop back to a 120 metal or insert a 50/70 hybrid transitional pad to bridge the gap.

Resin pad selection matters: softer resin bodies conform and cut better on wavy slabs but wear quickly; harder resins run cooler and last longer on flat floors but can skip on low spots. For planetary machines, I like a medium resin on the first two resin steps, then harder resins at 400 and beyond to hold edge definition. Keep rpm moderate—typically 400–550—so you’re refining, not melting. Heat is the enemy of resin life and clarity. If pads get hot to the touch, slow your head speed, lighten your weight, or add a light water mist for a semi-dry pass. Vacuum frequently; fines trapped under resins scratch like sand.

Densifier timing is your insurance. On soft slabs, apply densifier after 100 or 200 resin to firm the paste before you chase clarity. On tight, hard slabs, you might densify earlier if you struggled to cut at metals; on many shop floors, I’ve had the best luck densifying once the surface is open and uniform but before 400 resin, so the chemistry bridges pores and supports shine without sealing in metal furrows.

Common surprises and fixes:

- Ghost scratches at 400: You switched too early or skipped too far. Drop back to 120 metal or run a 50/70 hybrid, then re-do 100/200 resins.

- Swirl marks: Over-speed or loaded pads. Clean pads, slow rpm, and reduce weight.

- Sticky paste: Soft slab plus heat. Densify earlier and consider wetting lightly for the first resin pass.

- Uneven gloss near patches: Feather patches during metals and match resin steps carefully. Sometimes a spot application of densifier levels the behavior.

If you track pad life, note resin wear by square footage rather than hours; the slab’s hardness dictates replacement more than the clock. Keep a dedicated set of resins for edges to avoid cross-contaminating grits between tools.

Edges, joints, and trouble spots

Edges can ruin a schedule if you leave them for last. Match your edge work to the field at every stage. With a 5- or 7-inch variable-speed grinder, run the same grit sequence as the main pass and crosshatch your strokes at a consistent angle to the wall. Don’t gouge: keep the guard kissing the base and let the outer third of the wheel do the work. If you’re keeping cream, go lighter on the pressure at edges to avoid blowing past the paste into aggregate. For salt-and-pepper or full exposure, blend your edge passes into the field by stepping in 3–4 inches and overlapping with the planetary’s path.

Control joints and cracks need a plan. Decide early whether you’re honoring or filling. If you’re filling, saw-cut clean edges after your first metal pass, vacuum thoroughly, and fill with fast-set polyurea. Shave flush within a tight window, then re-run your mid-metal grit across the joint to keep the scratch pattern continuous. If you fill too late, resins will skate over the softer filler and leave a dull ribbon.

Patches and soft spots behave differently. Feather patch transitions with your metals—light passes, wider overlap—and avoid cutting deep divots that resins won’t erase. Color mismatches can be minimized by stopping short of full aggregate in those areas; you’re refining reflectivity more than trying to blend the mix.

Other trouble spots and fixes:

- Doorway curls: Spend extra time at metals to flatten. A single heavy pass with a coarser metal often beats three passes with a medium grit.

- Oil and stains: Degrease before grinding; heat from metals can drive contaminants deeper. If a stain persists, isolate and micro-etch, then re-densify in that area after 200 resin.

- High trowel burn: Hard, glossy cream needs a soft-bond metal or a hybrid/PCD scratch to open. Don’t waste time with resins until you see a uniform cut.

- Soft powdery areas: Densify earlier and possibly twice—once after 80/120 metal, again after 200 resin—light coats, proper dwell.

Quick edge-work tips:

- Keep a dedicated edge-vac with a clean filter; fine dust kills suction and leaves grit that scratches.

- Use a knee dolly or stable pads for long runs—comfort equals consistency.

- Mark your edge grit on blue tape along the wall; you’ll know exactly where you left off when the main machine catches up.

Seal, burnish, and maintain the gloss

The final act turns clarity into durability. A penetrating densifier hardens; a guard or micro-sealer adds stain resistance and boosts reflectivity. Pick a guard compatible with your densifier—lithium-based systems play best with lithium guards—and lay down thin, even coats with a clean microfiber flat mop. Less is more: two ultra-thin coats beat one heavy application that streaks. Watch your temperature and airflow; warm rooms and moving air flash coats faster and demand tighter sections.

Burnishing locks it down. Use a high-speed burnisher with the right pad—hogs hair, white, or a 3000-grit burnishing pad depending on the system. Make overlapping passes and don’t park the machine; heat and pressure are part of the shine, but too much in one spot glazes. If your spec calls for a matte finish, stop at 800 or 1500 resin and skip high-gloss guards; choose a penetrating protective treatment instead.

Maintenance is the difference between week-one gloss and year-three satisfaction. Daily dust mop with microfiber or treated pads keeps fines from acting like sandpaper. Use a neutral pH cleaner—nothing harsh—and autoscrub as traffic dictates; in shops, 2–3 times a week is common. Rotate to a diamond-impregnated maintenance pad monthly or quarterly to refresh micro-scratches. If the floor starts to look flat in the wheel paths, a quick 1500/3000 pass with a light guard recoat can restore pop in a single evening.

Safety and slip resistance matter. Many guards are rated; if you need more traction, consider a micro-etch cleaner during maintenance that increases coefficient of friction without dulling. Test in a small area. And always communicate expectations: polished concrete is beautifully honest—traffic patterns will show over time. That’s not failure; it’s a maintenance cue your crew can manage.

Practical finishing tips:

- Before guard, wipe the slab with a barely damp microfiber to lift fines that cause streaks.

- If a guard flashes too fast, cut it slightly per manufacturer guidelines or work smaller sections.

- Burnish only after the guard is fully dry—rushing leaves gummy trails that track.

DIAMOND PAD Concrete — Video Guide

If you’re a visual learner, there’s a solid demonstration of diamond pad workflow using color-coded twister-style pads paired with an ultra densifier. The video walks through the basics with a swing machine, showing how to open the floor, densify at the right time, and then climb through finer pads to build clarity. It’s a useful reminder that even without a large planetary grinder, you can still achieve a credible finish by focusing on sequence, even coverage, and patience.

Video source: DIAMOND PAD Concrete Polishing by Ultra Chem Labs

1000 Grit Sandpaper Sheets (25-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Gentle polishing grit that removes swirl marks and fine scratches on automotive or resin finishes. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: When do I switch from metal bond to resin pads?

A: Switch when the metal scratch pattern is uniform, the exposure goal is met, and a 3-by-3-foot test with your first resin removes the metal scratches cleanly. If you see deep lines at 100 resin, drop back to 120 metal or insert a 50/70 hybrid.

Q: Do I really need densifier for concrete polishing?

A: Yes, in most cases. Densifier hardens the paste, supports clarity at higher grits, and improves abrasion resistance. Apply after 100–200 resin on soft slabs or earlier after 80/120 metal when the surface is chalky or hard to cut cleanly.

Q: What grit should I start with on a typical garage?

A: If you’re keeping cream and the slab is fairly clean, test 60/80 metal. If the pad skates or you have coatings, step down to 30/40. Always test a small square and pick the lowest grit that cuts consistently without overcutting.

Q: Can I go wet with resins to reduce dust and heat?

A: Lightly misting or semi-wet passes can help on hard or hot floors, but manage slurry and avoid saturating the paste. Keep pads clean and vacuum between passes; wet fines create their own scratch risk if not removed.

Q: How do I handle very soft concrete that smears?

A: Use a harder-bond metal to prevent smearing, lighten machine weight, and reduce rpm. Densify earlier—after 80/120 metal—and consider a second light densify after 200 resin. Run resins cooler with slower head speed and frequent pad cleaning.