Best Lens Sanding Sequence for Plastic Headlights

Twilight is the worst time to discover your headlights are lying to you. Streetlights smear into blurry halos; lane markers fade into a matte wash. You feel yourself leaning forward in the seat as if posture could coax more lumens from the housings. But the problem isn’t the bulb; it’s the lens. Polycarbonate oxidizes, turns porous, and grows a diffuse surface that scatters light instead of transmitting it. That’s fixable if you stop thinking of restoration as a wipe-on miracle and start treating it like precision surface engineering. This guide is about real lens sanding—structured, wet, and sequential—not guessing with a single pad until it “looks better.”

Wet sanding isn’t glamorous, but it’s the difference between temporarily shiny and truly optically clear. The right abrasive progression reduces scratch depth in controlled steps until the surface scatters less than the threshold your compound can remove. The wrong progression traps deep scratches under a polished surface, leaving glow, ghost lines, or unfixable grit-induced furrows. What follows is a technician-level roadmap: how to evaluate the lens, choose materials, sequence the cuts, manage lubrication, and finish with a UV-stable topcoat so the clarity lasts.

If your headlights are the eyes of the car, then this is corrective surgery, not cosmetics. We’ll target specific failure modes—oxidation bloom, micro-pitting, and hardcoat failure—then prescribe an abrasive ladder that closes the defect depth in sensible micrometer increments. By the end, you’ll know exactly which grit to start with, where to stop, and how to verify that every coarser scratch has been fully erased before moving on. It’s slower than a kit, but it’s predictable—and predictability is what gets you consistent results.

Quick Summary: The best wet sanding sequence for plastic headlight lenses depends on defect depth; step through controlled grit stages, confirm uniform scratch replacement at each stage, then compound, polish, and lock in clarity with a UV-stable coating.

Assessing lens condition precisely

Before a single sheet touches the lens, quantify what you’re removing. Polycarbonate headlight lenses have a factory UV hardcoat (typically 10–20 microns thick) that degrades first. Once compromised, the underlying PC oxidizes, becomes porous, and accumulates embedded contamination and micro-pits from road grit. Your initial task is to decide whether the intact hardcoat can be refined or if it must be fully abraded.

Perform this triage:

- Visual and tactile mapping: Under a high-CRI light (≥90), look for yellowing, chalky bloom, and silvery micro-crazing. Drag a nitrile-gloved fingertip across the lens; a squeaky, dry feel implies surface oxidation or broken hardcoat.

- Water-break test: Mist water. If it beads tightly in patches and sheets in others, the hardcoat is patchy. Uniform sheeting suggests even oxidation.

- Magnification: Use a 10x loupe. Note pit size and depth; if you see discrete craters with sharp rims, plan a more aggressive start.

- Edge risk: Headlight edges and raised lettering are thin. Mark these zones with painter’s tape and plan lower pressure there.

If the hardcoat is intact but only lightly oxidized, stay conservative; refining and re-sealing saves material. If the hardcoat is compromised or peeling, commit to full removal and resurfacing.

Prep workflow:

- Wash with pH-neutral shampoo to remove grit. Decontaminate with isopropyl alcohol (IPA 10–20% in water) to strip silicone and wax.

- Mask paint, rubber, and trims with quality automotive tape; add plastic sheeting to protect adjacent surfaces from slurry.

- Temperature control: Work in 15–27°C ambient. Polycarbonate softens with heat; avoid direct sun. Keep the lens cool to the touch throughout.

- Choose your tooling: For complex curves, a 3” dual-action sander with a 3–5 mm interface pad distributes pressure evenly. For tight edges, use a firm rubber block or finger wraps to maintain flatness.

Commit to a verification discipline: each step must end with a uniform, matte, no-gloss surface where every previous scratch is replaced by a finer, consistent scratch pattern. Anything short of uniformity compounds regret—literally.

Optimized lens sanding sequences by severity

The “best” sequence is the one that matches defect depth while minimizing unnecessary material removal. Use FEPA “P” grits and waterproof abrasives. Typical particle sizes: P600 (~26 µm), P800 (~22 µm), P1000 (~18 µm), P1500 (~13 µm), P2000 (~10 µm), P3000 (~6–8 µm). According to a article, wet sanding is the controlled approach to remove oxidation and restore clarity; the key is verifying each stage replaces the prior scratch pattern fully.

Light oxidation, hardcoat intact:

- Starting point: P1500 wet. Goal is to refresh the topcoat without over-cutting.

- Sequence: P1500 → P2000 → P3000, then compound and polish.

- Method: Cross-hatch strokes (0°/90°) with light pressure (≈1–2 psi). 10–15 passes per axis, keep the surface flooded. Expect 5–7 minutes per lens.

Moderate oxidation, early pitting, hardcoat compromised:

- Starting point: P1000 wet to remove yellowing and shallow pits.

- Sequence: P1000 → P1500 → P2000 → P3000.

- Method: Use a 3” DA with a 3–5 mm foam interface to prevent faceting curves. Work in small tiles (~5x5 cm), refining to a uniform matte before moving on. 8–12 minutes per lens sanding time.

Severe oxidation, micro-pitting, or abrasion scars:

- Starting point: P600 or P800 wet depending on pit depth. If a fingernail barely catches pits or sanding gouges, start at P600; otherwise P800.

- Sequence: P600 → P800 → P1200 → P2000 → P3000. Optionally add P2500 if you’ll finish by hand.

- Method: Limit P600 exposure near edges; feather pressure and shorten dwell. Verify the pit field is gone before upshifting grits; leaving pits forces rework. 12–18 minutes per lens.

Execution controls for any sequence:

- Lubrication: Use water with a drop of pH-neutral car shampoo to break surface tension; re-wet every 20–30 seconds. Do not allow a dry slurry—it creates rogue scratches.

- Stroke discipline: Change axis with each grit so you can visually confirm scratch replacement. A quick IPA spritz flashes off water to reveal stragglers.

- Paper management: Replace sheets as soon as the cut rate drops (often 1–2 lenses per sheet for coarse grits; more for fine). Loaded paper burnishes instead of cutting.

- Edge strategy: Reduce pressure by 50% at perimeters and around raised characters. Consider hand-finishing these areas with the next finer grit to avoid thin-spotting.

Stop the abrasive ladder when the P3000 finish shows a uniform, silky grey with no directional scratches. If you can see a predominant scratch orientation after P3000 under raking light, you skipped replacement at an earlier stage.

Abrasives, lubricants, and scratch control

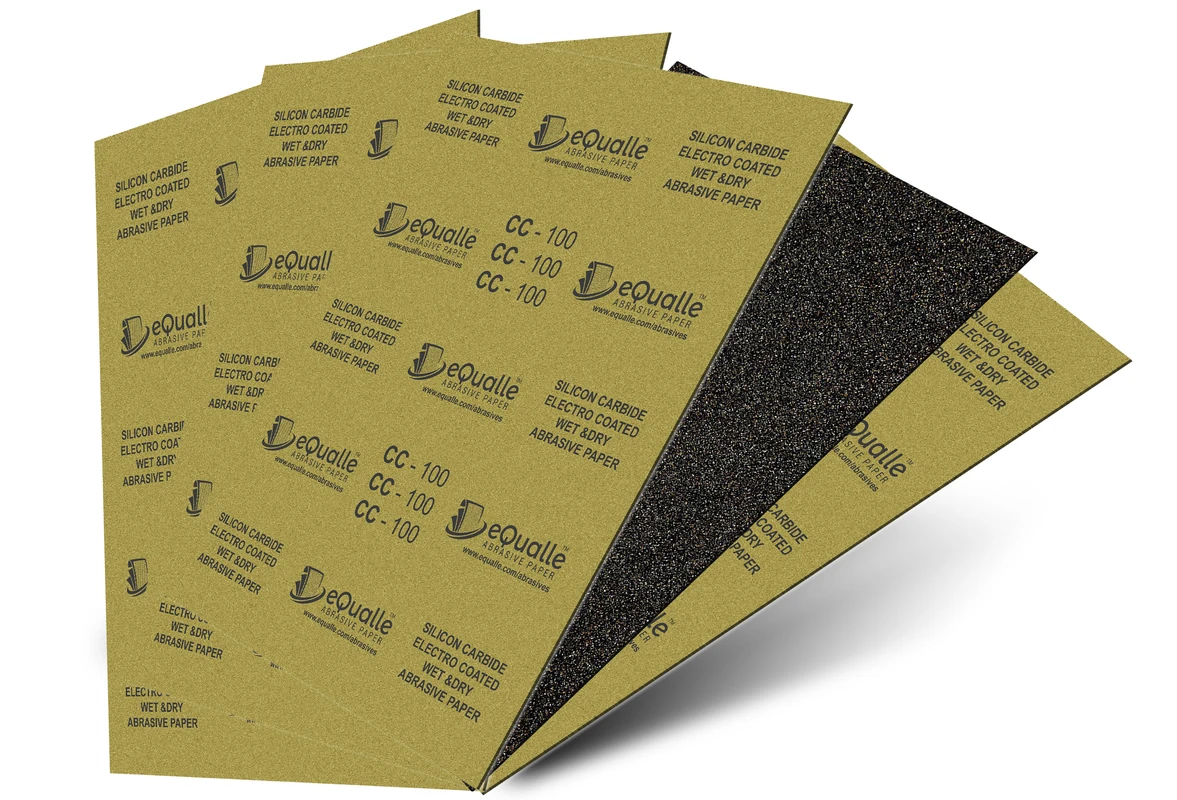

Abrasive selection determines consistency. For plastic headlight work, silicon carbide “wet-or-dry” sheets cut cool and sharp, especially in coarse grades. For mid-to-fine steps, film-backed discs provide flatness and predictable scratch geometry; foam-backed micro-abrasives (e.g., engineered 3D pyramids) at P3000 and up excel at refining without edge bite.

Materials and mechanics:

- Abrasive media: SiC excels in wet cutting on polycarbonate, fracturing to maintain sharpness. Alumina films in finer grades (P1500–P3000) generate uniform, shallow scratches that polish out readily.

- Backing and conformity: Use a soft (3–5 mm) interface pad on curved lenses to avoid flat spots. For hand work, a semi-firm rubber block maintains planarity across broad areas; finger wraps are for edges only.

- Machine dynamics: A 3” DA at 8–10k OPM with 2–3 mm orbit reduces hologram risk on thermoplastic substrates. Keep pad speed moderate—let grit do the work.

Lubrication and contamination control:

- Fluid: Clean water plus a few drops of neutral shampoo (0.1–0.2%) prevents clogging and maintains a mobile slurry. Avoid silicone-laden soaps; they inhibit later coatings.

- Slurry management: Squeegee the lens between passes to inspect the scratch floor. Wipe with a clean microfiber dampened with IPA to expose true surface.

- Cleanliness: Any stray grit is a deep scratch waiting to happen. Keep a dedicated rinse bucket and swap towels frequently. Do not lay paper face-down on dirty surfaces.

Scratch visualization and heat:

- Witness marks: Before starting a new grit, draw a faint grid with a dry-erase marker. When the grid is uniformly erased, you’ve replaced the previous scratch set.

- Lighting: Use a raking beam at ~15° to exaggerate topography. Rotate your viewing angle with each grit.

- Temperature: Keep the surface under 45°C; polycarbonate softens, and heat promotes smearing. If it feels warm, pause and re-wet.

Actionable tips for superior scratch control:

- Track time per tile: If P1000 needs ~60–90 seconds per 5x5 cm area to clear oxidation, anything less risks undercut; anything more suggests dull paper.

- Retire paper early: When water no longer turns grey within 3–4 strokes, the sheet is glazing—replace it to maintain a consistent cut.

- Use a glide test: After each grit, pull a clean nitrile glove fingertip across the surface; a uniform “buttery” drag indicates consistent topography.

- Microfiber discipline: Color-code towels by step (e.g., blue for slurry, grey for IPA) to prevent cross-contamination.

Run the process like metrology, not guesswork. The surface will tell you exactly when to move on—if you create conditions to hear it.

Finish, protect, and validate results

Sanding only sets the stage. To convert a uniform matte into optical clarity, you need a two-phase polish and a durable UV barrier.

Compounding and polish:

- Compound: Use a plastic-safe diminishing abrasive compound on a 3” DA with a medium foam pad (orange). 2–3 section passes at moderate pressure remove the P3000 footprint. Keep pad flat and clean residue frequently to avoid reintroducing micro-marring.

- Polish: Switch to a fine finishing polish on a soft foam (black) pad. One or two light passes refine to full clarity. Wipe residues with clean, low-lint microfiber.

Surface prep for coating:

- Degrease: Final wipe with 10–20% IPA in distilled water. Avoid heavy solvents; they can craze polycarbonate.

- Dust control: Let the lens air-set for a minute to release solvent vapors before coating.

UV protection options:

- 2K urethane clear: Best long-term durability (12–24 months or more). Spray two light coats with proper PPE; isocyanates are hazardous. Aim for thin, even film to preserve optics.

- Wipe-on polymer/UV sealer: Easier and safer, but shorter life (6–12 months). Apply thin, allow full cure per product, and avoid moisture during cure.

- Ceramic topcoats: Provide hydrophobicity but minimal UV absorption on their own; use only over a UV-blocking layer.

Validation:

- Beam test: After cure, project headlights against a wall at dusk. Look for tight cutoffs without halo and confirm aim hasn’t shifted from masking or sanding.

- Gloss and haze: Use a gloss meter if available, or evaluate under a raking light. You’re looking for uniform specular reflection with no linear residuals.

- Water behavior: A uniform, slow sheeting pattern often indicates an even coating film; erratic beading suggests application inconsistency.

Maintenance:

- Wash with pH-neutral soaps; avoid abrasive cleaners.

- Top up wipe-on sealers periodically per manufacturer guidance.

- Keep an eye on early signs of UV fatigue (mild haze); a light P3000 and polish refresh can extend life before full rework is needed.

How To Restore — Video Guide

For perspective on sanding discipline, see a walkthrough that restores a badly pitted glass headlight lens using progressive sanding and polishing. The presenter demonstrates a grit ladder, continuous lubrication, and inspection between stages—good habits that translate directly to plastics, even though glass needs different abrasives and can tolerate more heat.

Video source: How To Restore Your Glass Headlight Lenses? Sanding And Polishing!

1500 Grit Sandpaper Sheets (25-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Refining grit that bridges polishing and buffing—perfect for restoring a subtle satin or semi-gloss look on painted finishes. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: Can I dry-sand plastic headlights to go faster?

A: Avoid dry sanding on polycarbonate. Wet sanding controls heat, carries debris away, and reduces random deep scratches. Dry sanding raises temperature and smear risk, which can permanently haze the lens.

Q: My lens shows “crazing” lines under the surface. Will sanding fix it?

A: No. Crazing is subsurface stress cracking within the polycarbonate. Sanding can remove surface oxidation but cannot eliminate internal fractures. You can improve clarity, but lines may remain faintly visible.

Q: What if I can still see scratches after polishing?

A: That indicates an earlier grit didn’t fully replace the previous scratch pattern. Backtrack one step in the sequence (e.g., from P3000 to P2000), re-establish a uniform matte, then proceed through finer stages and repolish.

Q: Is the sequence different for glass headlights?

A: Yes. Glass uses different abrasives (often ending with cerium oxide) and tolerates higher temperatures. The sequencing logic is similar, but grit ranges and polish chemistry differ. Do not use plastic-specific coatings on glass without compatibility checks.

Q: Which UV coating lasts the longest?

A: A properly applied 2K urethane clear typically outlasts wipe-on sealers. It provides robust UV absorption and chemical resistance. Use appropriate PPE and follow curing protocols to ensure adhesion and longevity.

Q: How often will I need to redo the restoration?

A: With a 2K clear, expect 12–24 months or more depending on climate and care. Wipe-on UV sealers generally last 6–12 months. Gentle washing and periodic top-ups extend service life.