Task Matching by Sandpaper Grit: A Practical Guide

The project usually begins with confidence: a sunny Saturday, a coffee within reach, and a table or bike part you’re finally ready to refresh. You pull out the sander, grab whatever sandpaper is on top, and get to work. Ten minutes later, the surface looks worse—deep scratches in one spot, shiny untouched coatings in another, and dust everywhere. It’s a moment most DIYers and even pros have felt: the work is happening, but progress isn’t. The missing piece is rarely effort. It’s almost always selection—specifically, matching the task to the right sandpaper grit.

“Grit” isn’t just a number; it’s your steering wheel. The right choice determines how quickly you cut through coatings, how consistently you flatten a surface, and how smooth your final finish looks and feels. The wrong grit wastes time, burns material, and can set you back multiple steps. When you understand grit ranges and how they pair with materials (wood, metal, paint) and tools (orbital sander, sanding block, belt sander), everything gets easier. Your sanding becomes purposeful instead of reactive. Edges feather cleanly. Grain rises predictably. Primer levels flat. And you stop guessing.

In this guide, we’ll map common tasks to ranges that work—starting coarse enough to be effective, then stepping through to a finer finish with as few stages as possible. We’ll also cover tool pairings, pressure, scratch patterns, and how to avoid the most common mistakes that leave swirls, lines, or dull spots. If sanding has felt like a chore, you’ll leave with a process. More importantly, you’ll finish with surfaces you’re proud of—ready for stain, paint, clear coat, or that soft, burnished touch that invites a hand to glide across.

Quick Summary: Choose the coarsest grit that safely solves the current problem, then move through logical grit jumps that erase the previous scratches without oversanding.

Start smart: reading the surface

Before you reach for any abrasive, read the surface like a checklist. Your goal is to identify the “job to be done” so you select the sandpaper that does it quickly without damage.

First, consider the material. Pine dents easily and clogs paper; oak resists cutting and shows scratch patterns; plywood has thin veneers that you can burn through; metal reveals high and low spots more dramatically; old paint can be gummy or brittle depending on age and chemistry. Each demands a different starting grit.

Second, note the current condition. Are you removing finish, flattening, smoothing, or polishing? Removing finish or leveling seams calls for coarse grits that cut quickly. Smoothing and pre-finish work call for mid-range grits that refine without deepening scratches. Polishing and intercoat work rely on fine and very fine grits that nibble rather than slice.

Third, look at defects. Deep scratches, glue squeeze-out, runs and drips, dents, and sanding swirls each point to a task. If you can feel it with a fingernail, you need a coarser grit to level it; if it’s only visible at certain angles, a mid or fine grit can likely erase it.

Finally, match your tool. An orbital sander is a versatile generalist for most wood and paint tasks. A belt sander is a fast, aggressive flattener. A sanding block gives you control on edges and profiles. For automotive finishing and clear coats, hand sanding or a soft-backed interface with an orbital helps maintain delicate curves.

Three quick tips to start right:

- Do a test pass on a hidden area with one grit. If it’s slow, step coarser; if it scars, step finer.

- Mark the surface lightly with pencil crosshatch; when the marks disappear uniformly, you’re flat.

- Keep a vacuum or brush at hand; dust hides defects and overheats paper, slowing the cut.

Decoding sandpaper grit ranges by task

You’ll work faster and more consistently if you think in grit ranges rather than single numbers. Within each range, aim to make the smallest number of passes that remove the previous scratches.

Heavy removal and flattening (P24–P60): For stripping thick finishes, leveling cupped boards, knocking down welds, or shaping edges. Choose P24–P36 for aggressive stock removal on hardwood or metal; P40–P60 for controlled removal on softer woods or paint. Expect visible scratch patterns that must be refined.

General shaping and prep (P80–P120): P80 is the “workhorse” for flattening planer marks in wood, removing light rust, or cleaning paint drips. P100–P120 refine surfaces without biting too deeply. Stop here if you’re priming paint or if the next step is a filler; you want enough tooth for adhesion.

Pre-finish smoothing (P150–P220): This is the zone where wood begins to feel smooth but still accepts stain evenly. P150 is a great transition if you started at P80. P180–P220 will erase visible scratches while preserving crisp edges. For painted finishes, P220 is often the last grit before primer.

Between coats and fine finishing (P240–P400): After your first coat of finish or primer, nibs and raised grain need a light scuff. P240–P320 removes dust bumps without cutting through. P320–P400 is common before the final color coat or clear, especially on cabinets or doors.

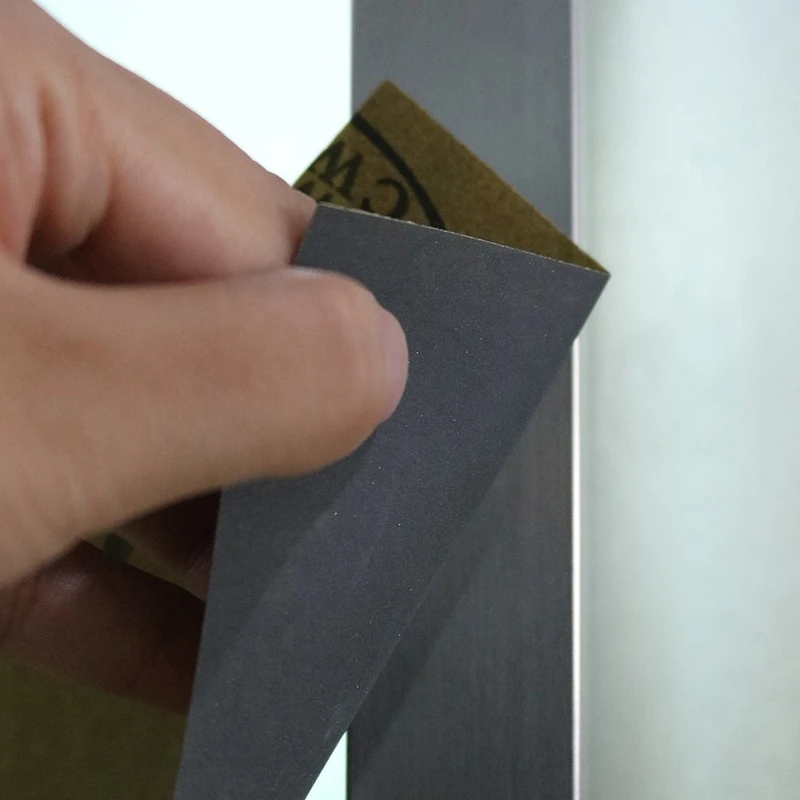

Polishing and precision (P600–P2000+): These grits serve automotive finishes, metal polishing, or lacquer work. P600–P800 feathers edges and levels orange peel; P1000–P2000 refines for high-gloss buffing. Use wet sanding to control heat and loading, especially on paint and metal.

Guideline for grit jumps: From coarse to mid, jump roughly 50–80% higher (P80 → P120 → P180). From mid to fine, tighten the jumps (P180 → P220 → P320). Each step should remove the previous scratches in 2–4 passes.

Wood projects: from rough to finish

For wood, your approach depends on species, tool marks, and final coating. Start by removing defects with the coarsest grit that doesn’t gouge, then refine efficiently.

Planed hardwood with light ridges: Start at P100 or P120 to erase machine marks. Move to P150, then P180 or P220 depending on stain choice. Dark stains highlight scratches; stop at P180 to leave enough tooth and avoid burnishing. Clear coats on light woods often look best at P220.

Rough-sawn or reclaimed boards: Begin at P60–P80 to flatten and remove aged surface fibers. Use a straightedge to detect high spots. Progress to P120, then P180. For tabletops, add a final P220 to help with even finish absorption.

Softwoods (pine, spruce): Softer fibers compress and rebound, which can create washboarding. Start at P100 to reduce risk of tearing. Move to P150 and then P180. If you go too fine before sealing (e.g., P320), you can close off pores and cause blotchy stain.

Veneers and plywood: Stay conservative. Start no coarser than P120. Move to P150 and P180. Minimal pressure protects the thin face layer. Use a sanding block or a firm pad to avoid rolling over edges.

Actionable tips for wood:

- Damp-wipe between P150 and P180 to raise grain, let dry, then resand at the same grit for a truly smooth pre-finish surface.

- Sand with the grain for the final grit stage to minimize cross-grain scratches that telegraph through stain.

- Use a soft interface pad on an orbital sander for curved chair parts; it keeps contact even and reduces flats.

- Mark defects (glue squeeze-out, dents) with painter’s tape before you start so you don’t sand past them unintentionally.

Metal, paint, and auto body tasks

Metal and coatings behave differently from wood. Heat, loading, and the tendency to skate across hard surfaces change how grit cuts. Your choices should balance speed with control.

Bare metal prep: For weld cleanup or rust removal, start around P36–P60 using a flap disc or heavy-duty paper. Step to P80–P120 to remove deep scratches. For parts heading to primer, P120–P180 gives sufficient tooth without grooves.

Paint removal and feathering: Old, brittle finishes come off cleanly with P60–P80; gummy coatings may respond better to a chemical stripper followed by P120. When feathering paint edges for repair, P180–P240 blends the transition. Avoid digging—light pressure and a firm backing pad help.

Primer leveling and between coats: After primer, sand with P320 to flatten and P400 for final pre-color smoothness. You’re correcting nibs, not re-leveling the substrate. Keep the surface clean to avoid embedding grit from previous steps.

Clear coat smoothing and polishing: For orange peel or dust nibs, use P600–P800 wet. Then progress to P1000–P1500 before compound and polish. Stay patient: too coarse at this stage leaves texture that takes more polishing time later.

According to a article, coarse grits (24–36) are reserved for heavy correction, while 600 and above make delicate paint corrections manageable—an excellent reminder to let the task dictate the grit. When in doubt, test on a masked boundary and inspect under bright, angled light. Metal and paint reveal everything; your grit choices should leave the least work for the next step.

Tools, techniques, and fixes

Even perfect grit selection can be undermined by the way you sand. Technique controls heat, scratch uniformity, and how efficiently each grit erases the one before it.

Tool pairings:

- Orbital sander: Best for general flattening and refinement from P80 to P320. Use a quality hook-and-loop pad and consider a soft interface for contours.

- Belt sander: Reserved for aggressive leveling with P36–P80. Keep it moving and flat; tip-toeing digs divots fast.

- Sanding block: Essential for edges and hand-leveling at P120–P220. A cork or rubber block distributes pressure evenly.

- Wet sanding: For P600 and above on paint and metal. Use clean water with a drop of dish soap to lubricate and carry away swarf.

Technique fundamentals:

- Pressure: Let the abrasive cut. Extra pressure dulls grit, creates swirls, and slows removal. If it feels slow, step to a coarser grit rather than pressing harder.

- Motion: With orbitals, guide the tool slowly—roughly 1 inch per second—without lingering. Overlapping passes by one-third ensures uniform coverage.

- Dust extraction: Hook up a vacuum if possible. Removing dust keeps abrasive sharp longer and reduces clogging (“loading”), especially on resinous woods and paint.

Common fixes to keep you on track:

- Swirl marks: Usually from too coarse a grit or a worn pad. Step one grit finer and replace the pad if it’s hardened. Finish with a with-the-grain hand pass.

- Pig-tail scratches: Caused by a single trapped particle under the pad. Stop, clean the pad and surface, and resand with the previous grit until the mark disappears.

- Glazing and loading: Paper turning shiny is a sign it’s full. Clean with a rubber abrasive stick or switch sheets. On gummy finishes, use stearated papers and lighter pressure.

- Over-sanding edges: Use a sanding block and fewer passes at edges, or tape them off during early coarse stages.

- Skipping grits: If P120 won’t remove P60 scratches quickly, you skipped too far. Insert the missing step (P80 or P100) to save time overall.

How Do I — Video Guide

New to furniture flips or just want a refresher on grit sequencing? This video walks through how to choose grits for each stage of a furniture refinish, from stripping and leveling to smoothing and scuff-sanding between coats. You’ll see how starting slightly coarser speeds early tasks, then tightening grit jumps creates a clean, finish-ready surface.

Video source: How Do I Sand Furniture? | Sandpaper Grit 101 - Know Which Grit to Use for Each Step of Your Flip!

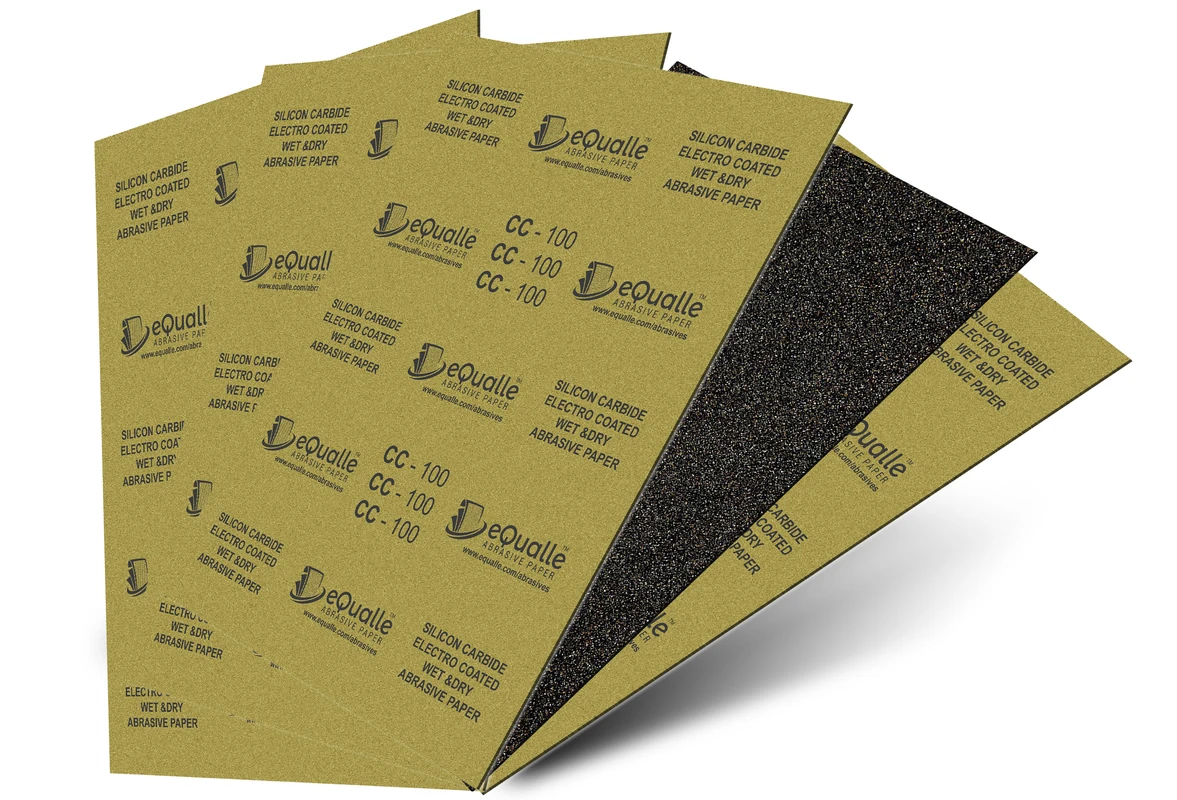

360 Grit Sandpaper Sheets (25-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Precision grit for removing haze and small surface defects. Ensures scratch-free sanding on wood, plastic, or metal. Ideal for both wet and dry use before the polishing stage. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: What grit should I start with for a scratched wooden tabletop?

A: If scratches are felt with a fingernail, start around P80 to level them quickly. Then move to P120, P180, and stop at P220 before finish. For light hairline marks only visible at an angle, start at P120 instead.

Q: How big should my grit jumps be?

A: Early stages can jump roughly 50–80% (P80 → P120 → P180). As you approach finish, tighten steps (P180 → P220 → P320) so each stage erases the previous scratches in a few passes.

Q: Do I need different grits for paint versus stain?

A: Yes. Paint benefits from a slightly coarser pre-coat surface for adhesion (often P220 before primer, P320 before topcoat). Stain highlights scratches, so wood often stops at P180–P220 to balance smoothness with even color uptake.

Q: When should I wet sand?

A: Use wet sanding from P600 and above on cured paints, clear coats, and metal to control heat and loading. Avoid wet sanding raw wood; water raises grain and can cause swelling or uneven texture.