Surface Leveling: Sanding Uneven Wood Panels Flat

On a cool Saturday morning, your glue-up looks perfect from three paces away. The seams are tight, the grain lines match, and you’re already picturing the finish. Then the raking light hits—tiny ridges, a clamp bump here, a cup there. You run a straightedge across and hear that hollow tick in the middle. No planer, no drum sander, and only the shop basics on your bench. This is where the craft begins, not where it ends. With deliberate handwork, smart tool choice, and disciplined grit progression, you can achieve precise surface leveling using sanding alone. The key is to treat the panel like a system: track where the highs are, remove stock only where you must, and lock in flatness before you chase scratches. If your project is an heirloom tabletop or a cabinet door set, your workflow doesn’t change much—what changes is your patience and how clearly you can “see” the surface as you sand. I’ll show you my repeatable process for flattening panels by hand, with nothing more than sandpaper, a few blocks, and a healthy respect for dust control and measurement. You’ll learn to read the wood, choose the right grit sequences, and avoid common traps like rolling edges or leaving a subtle dish that ruins your finish. This is hands-on, no-nonsense surface leveling tailored for real shops and real projects.

Quick Summary: We’ll flatten uneven wood panels with sanding only, using targeted abrasion, rigid blocks, pencil mapping, and smart grit progressions to achieve dead-flat, finish-ready surfaces.

Know Your Panel and Its Problems

Before you sand, diagnose. Two panels can look equally “wavy” but require very different strategies. Your first pass is all about mapping high spots, understanding wood movement, and choosing the direction that fights the fewest grain issues.

Start with measurement:

- Straightedge check: Lay a reliable straightedge across multiple diagonals and along the length. Note where it rocks and where gaps appear.

- Pencil map: Scribble light pencil crosshatching over the entire face. Each pass will erase pencil on the highs first, giving instant feedback.

- Winding sticks: Place them near the ends, sight across, and check for twist. If you see a step, you’ve got torsion to address.

Now take stock of the glue-up. If you alternated growth rings and matched grain direction, sanding will be friendlier. If boards switch grain sharply, you’ll need to adjust stroke direction or choose grits that are less prone to tearing fibers.

Choose the right approach:

- If the panel is crowned (high in the middle), you’ll target the center in measured strokes with a long, rigid block.

- If it’s dished (low in the middle), you’ll work the perimeter lightly, then unify the field—resist the urge to overwork the low spot.

- For ridged glue joints, concentrate on knocking down each ridge selectively before blending.

Three field-proven tips:

- Always sand along the dominant grain direction for leveling passes, then cross-grain very lightly only if needed to blend; return to with-grain strokes immediately.

- Keep your pressure even and your block flat—your body position matters. Stand so your shoulders are square to the stroke, and push with your torso, not just your arms.

- Vacuum between grits; dust packs scratches and keeps you blind.

Your diagnosis is your roadmap. Get it right, and every stroke has a job.

Dialing in Surface Leveling by Hand

The heart of surface leveling is controlling the shape of the panel as you remove material. Your sanding block is your “mobile plane sole,” and your technique turns random grit into geometry.

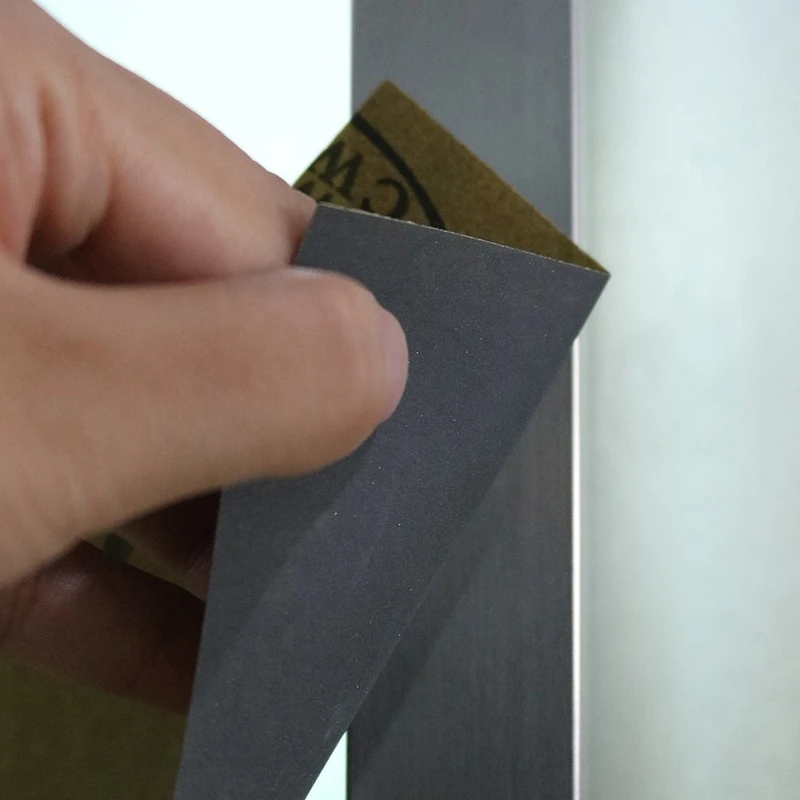

Start with a rigid, flat block. I like a 16–18-inch MDF stick with cork or PSA interface pad. The length bridges valleys and shaves down the highs without telegraphing your fingertip pressure. Wrap it with quality paper—no creases. If you have a known-flat slab or tool, check the block’s face occasionally.

The first passes are targeted. Use your pencil map as a live readout:

- Make 6–10 controlled strokes over each high glue line, long enough to overlap into the field.

- When ridge tops dull, shift to long with-grain strokes, working the crown first if present.

- Re-map with pencil after every short cycle; your goal is uniform pencil fade, not speed.

Don’t chase low spots. Sanding the low areas harder only deepens the bowl. Instead, bring the surrounding highs down until the low begins to disappear in your pencil map and straightedge checks. For twist, concentrate on the two opposite high corners with a rigid block until the winding sticks read true.

Practical leveling tips:

- Use a “cap and carry” stroke: start on the panel, end off the panel to avoid creating a rounded exit lip.

- Slightly bias your grip toward the high side—just a touch—to focus removal without tipping the block.

- Count strokes. For example, three cycles of 10 strokes on each marked high will keep your approach symmetrical.

Patience pays. Each leveling cycle should be short and deliberate, followed by vacuuming and a fresh pencil map. When your straightedge no longer rocks and the gaps disappear under raking light, you’ve earned the right to think about scratch refinement.

Grit Progressions That Actually Work

The right grit sequence is your insurance against swirls, dishing, and wasted effort. Start coarse enough to move wood, then step cleanly so each grit erases the previous scratches without reintroducing waves.

For most panel leveling:

- Begin at 80 grit if you have measurable ridges or a stubborn crown. If the panel is close, start at 100 or 120.

- Move in these jumps: 80 → 120 → 150 → 180 → 220. Skip 100 if 80 cleans up quickly; add 320 only for film finishes that highlight every scratch.

- Don’t advance grits until all previous scratches are gone. Use crosshatch pencil lines to verify you’ve erased the earlier pattern.

A few realities:

- 60 grit is tempting but dangerous by hand; it removes fast and can dish the panel. Use it only for severe glue misalignment, and confine it to the highest spots with a long block.

- Cheap paper loses bite quickly and burns time. Quality stearated paper keeps cutting and sheds dust instead of clogging.

Step-by-step scratch control:

- Level with your coarsest chosen grit using a long block, with-grain strokes.

- Vacuum and re-map with pencil. If the pencil erases uniformly with a light pass, you’re flat.

- Rotate your block orientation 10–15 degrees during mid-grits (150–180) to reveal lingering coarse scratches, then finish the set with dead-with-grain passes.

- After 220, stop. Further grits can burnish early and interfere with finish adhesion.

According to a article

Two professional habits:

- Change paper early. If you’re pushing harder to get the same cut, the paper is dull, and you’re sculpting, not sanding flat.

- Use raking light at each grit change; low-angle LED lights expose scratches and subtle dips better than overhead lighting.

Your progression should feel like downshifting methodically, not meandering. The panel should look uniformly matte at each stage, with no shiny divots or ghost ridges.

Tools, Blocks, and Shop-Made Aids

You don’t need a machine park to get a panel flat; you need a few tuned helpers that magnify your skill. Build or buy these once, and your sanding results get predictably better.

Essentials:

- Long rigid block: 16–18 inches, MDF or Baltic birch with a thin cork face to distribute pressure without rounding. PSA-backed paper keeps the face dead flat.

- Mid-size block: 8–10 inches for local touch-ups around knots or end-grain transitions.

- Hard card scraper: While we’re “sanding only,” a sharp scraper is still useful for removing hardened glue before sanding—think of it as prep that saves your paper from clogging.

- Straightedge and winding sticks: Aluminum level works in a pinch; dedicated winding sticks make twist visible.

- Pencil and vacuum: Your feedback loop. A soft graphite pencil shows contact; a shop vac shows honesty.

Shop-made helpers:

- Sacrificial sled: A flat plywood board with 80-grit paper spray-glued on top. Move the panel across the sled like a jointer pass for precise spot-flattening of edges and corners.

- Dust shroud and hose clip: Keeps the vac hose parked at the bench edge so you actually use it between cycles.

- Raking light stand: A scrap board with a clamp light at knee height. Aim it across the surface to highlight defects.

Actionable setup tips:

- Elevate the panel on bench dogs or low risers so your strokes clear the bench and your wrists stay neutral.

- Keep two identical long blocks loaded with different grits (e.g., 120 and 150). Switching blocks keeps momentum without peeling paper.

- Mark the block face with the grit number in big digits—saves accidental cross-contamination.

As you refine, your tools should become quieter: less coarse raspiness, more controlled whisper. That’s how you know you’re letting the block do the geometry and the paper do the cutting.

How to Sand — Video Guide

There’s a practical walk-through I recommend: a hand-sanding demonstration focused on getting truly flat panels without any fancy machinery. It shows how to use long blocks, body position, and pencil maps to achieve that crisp flatness and clean edges.

Video source: How to Sand a Surface Perfectly Flat by Hand

500 Grit Sandpaper Sheets (100-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Soft-action abrasive for micro-smoothing metal, resin, or primer coatings where precision and uniformity are key. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: How do I know when to stop leveling and start refining scratches?

A: When your straightedge no longer rocks, your pencil map erases uniformly with a light pass, and raking light shows no localized highs, you’re flat. That’s your signal to move to the next grit and focus on scratch removal.

Q: Can I use a random-orbit sander for leveling a panel?

A: For heavy leveling, a random-orbit sander tends to follow contours and can dish the surface. Use a long rigid block to establish flatness first, then the ROS at mid-to-fine grits for scratch refinement while keeping strokes light and even.

Q: What’s the best grit to start with on a lightly uneven panel?

A: If ridges are faint and the surface is close, start at 120. It cuts cleanly without removing too much stock. If you still see ridges after a few cycles, back up to 100 or 80 for targeted high-spot work, then resume the sequence.

Q: How do I avoid rounding the edges while sanding?

A: Keep the block fully supported on the panel, use a “cap and carry” stroke that starts on the surface and exits off the edge, and avoid finger pressure at the ends. A chamfered block edge and light passes around the perimeter also help.

Q: My panel is flat but still looks wavy under finish. Why?

A: That’s scratch pattern telegraphing. You likely jumped grits or didn’t fully remove the previous scratches. Re-sand with raking light: go back one grit, erase all visible lines, then step up again, finishing with consistent with-grain passes at 180–220.