Abrasive testing to measure loading resistance over time

You only notice the fabric scuffing on a carry-on when the morning’s sprint through the airport slows down. The bag slides into the overhead, and you catch a glimpse: the corner patch is polished smooth, the weave thinning where it rubs the same ribbed aluminum edge on every trip. That glossy spot didn’t happen all at once; it’s the physical ledger of load, motion, and contact, summed over months. As a product engineer, I pay attention to those glossy spots. They tell a story about materials under repetitive stress and the slow drift of performance that can blindside even well-reviewed gear.

This is where abrasive testing earns its keep. It’s not just about how fast a sample loses weight against a grit wheel; it’s about measuring how a product’s loading resistance decays over time under realistic contact conditions. If you design luggage, footwear, upholstery, or industrial belting, the end user doesn’t experience “abrasion resistance” in isolation. They experience handle padding that packs down, textiles that fuzz and thin where straps bear against hardware, and molded parts that microcrack after thousands of cycles. The right test maps that reality to data: load, stroke, cycles, environment, and failure modes, all tied to time.

In the lab, we simulate those ribbed edges and grab points, then ask precise questions. How does coefficient of friction change during run-in? What’s the inflection point where mass loss rate spikes? Does a 12 kPa normal load predict field wear at 9 kPa with 20% higher humidity? The answers live in curves, not single numbers, and in controlled fixtures that let us vary only one thing at a time. Over months of testing, I’ve found that when our abrasion rigs log force, displacement, and roughness alongside cycles, we can predict when that glossy spot appears—and by how much.

Quick Summary: This guide shows how to design, run, and interpret abrasive testing to quantify loading resistance over time, turning wear mechanisms into actionable durability decisions.

Why loading resistance changes over time

“Loading resistance” sounds static, but it’s dynamic—the material response evolves with contact history. Three mechanisms dominate: micro-cutting and plowing (material removal), fatigue microcracking (subsurface damage), and surface conformity (densification, glazing, or pile flattening). Which one leads depends on the pairing of material, counterface roughness, and load.

At the start of a test, surfaces are “as-finished.” For textiles, loose fibers are sheared during run-in; for elastomers, asperities flatten and raise true contact area; for coatings, the topmost weak boundary layer abrades or burnishes away. This run-in can decrease friction as asperities shear off—or increase it if the surface becomes more conformal. Either way, the system’s stress distribution changes, shifting from asperity-limited to area-limited contact. That shift changes how the same load translates into local stress and thus wear rate.

Time under load also activates viscoelastic creep and consolidation, especially in foams and laminar fabrics. A handle wrap can appear intact but lose thickness and energy absorption, effectively lowering its loading resistance with cycles. Thermally, repeated frictional heating can soften polymers, alter binder properties, or dry lubricious finishes, driving a mid-test transition in wear mode. Humidity does the opposite for hydrophilic fibers: increased moisture can plasticize and reduce brittleness, delaying crack formation but sometimes increasing plowing.

The punchline: loading resistance is a trajectory. If your test reports only an endpoint (e.g., mass loss after 10,000 cycles), you miss the critical “when” and “how” of change. That’s why a useful protocol logs coefficient of friction (COF), normal load, temperature, and surface roughness over time, then aligns those with microscopy to identify the dominant mechanism in each stage. Only then can you correlate lab cycles to field service intervals.

From loads to wear: abrasive testing that matters

To measure loading resistance over time, we repurpose and tune established abrasive testing methods to emphasize time-resolved data. Common fixtures include:

- Wyzenbeek (ASTM D4157): oscillatory rubbing of fabric against a standard abradant under controlled tension and load. Great for upholstery and luggage textiles when you care about cycles-to-break or grade-based visual changes.

- Martindale (ISO 12947 / ASTM D4966): multi-directional rubbing with specified normal loads (typically 9 or 12 kPa). Useful for comparative pilling/fuzzing and thickness loss on woven/knit fabrics.

- Taber Rotary Abraser (ASTM D4060): rotating specimen under loaded abrasive wheels (e.g., CS-10, H-18) with defined vacuum. Strong for coatings, leathers, and plastics where mass loss and haze are key.

- Concrete/ceramic surfaces (ASTM C944): rotating steel cutter under load. A reminder that even hard materials’ wear rates depend on contact pressure, speed, and moisture.

What “matters” is mapping the rig to the field. Luggage corner wear resembles Wyzenbeek contact geometry more than Martindale because of the directional rubbing against an edge radius. For polymer feet on luggage, Taber with H-18 wheels under a 1,000 g load at 72 rpm may better emulate airport floors. In both cases, I log COF at ≥10 Hz to capture run-in and intermittent stick-slip; I monitor surface temperature with a 0.5 mm thermocouple taped near the contact patch; and I record thickness changes every set number of cycles using a 0.01 mm resolution gauge, not just at the end.

Beyond the rig, select relevant endpoints: cycles to first thread break; Δmass per 1,000 cycles; Δthickness; COF stabilization time; visual grade change index; and SEM-confirmed mechanism transition. With those, you can tell a product manager, “Under 9 kPa normal load, we retain 80% thickness at 15,000 cycles and hit first warp break at 22,000. The mechanism changes from fibrillation to yarn rupture around 18,000 cycles.”

Designing a repeatable wear experiment

Repeatability is hard in wear testing because surfaces evolve. Lock down the variables you can control, then let time resolve the rest. My checklist:

- Counterface control: For Wyzenbeek, replace abradant per standard cycle limits and verify its roughness (Ra) with a portable profilometer. For Taber, dress or replace wheels on schedule and precondition for 50 cycles to stabilize.

- Load and alignment: Calibrate load cells weekly. Use torque-limiting clamps to set fabric tension uniformly. Confirm parallelism with feeler gauges; even 1° tilt skews pressure distribution.

- Environment: Hold temperature to 23 ± 2°C and relative humidity to 50 ± 5%. Condition specimens at least 24 hours. Hygroscopic fibers demand consistency.

- Data acquisition: Sample COF and normal force at ≥10 Hz. Log temperature at 1 Hz. Capture cycle count and any auto-stop events. Use time-stamped files to align microscope images with data features.

According to a article

For study design, power matters. Wear data are heteroscedastic—variance increases with cycles. Plan 6–10 replicates per material and use blocked randomization for rig position to cancel spatial effects. Test to both a fixed-cycle endpoint and a failure endpoint on different replicates; the former supports rate comparisons, the latter supports survival analysis.

Metrics to compute during and after the run:

- Specific wear rate, k ≈ (Δmass)/(density × load × sliding distance). Trend k over time; a rising k indicates a mechanism shift.

- COF run-in length: cycles to reach within ±5% of steady-state COF. Shorter run-in can mean more stable interfaces—or overly brittle surfaces that skip to fracture.

- Thickness retention curve: thickness_t/thickness_0 vs. cycles. The curvature reveals densification fronts in foams and nonwovens.

- Hazard rate for failure events: d(ln S)/d cycles where S is survival probability, to locate cycle regions with heightened risk.

Actionable tips:

- Pre-screen counterfaces: Reject abradants with Ra outliers >10% from spec; they inflate scatter.

- Use marker cycles: Pause every 2,500 cycles for standardized photos; the picture log catches failure precursors.

- Normalize sliding distance: Report per meter rubbed, not just per cycle; stroke length varies across rigs.

- Add dummy loads: If the product includes hardware, mount it; absent hardware, add equivalent mass to match contact pressure.

Interpreting curves, not just endpoints

A single number—mass loss after 10,000 cycles—rarely predicts field life. Curves show you the transitions that matter. The COF curve usually has three phases: initial run-in (COF trending down as asperities shear or up as conformity rises), steady-state (plateau), and late-stage instability (COF spikes as debris accumulates or fibers rupture). Aligning those phases with thickness and mass loss curves gives mechanism-level insight.

Thickness retention curves for textiles often show a concave-down shape early (rapid flattening), then a linear region, then an inflection when yarns break. If thickness loss slows but mass loss accelerates, you’ve shifted from compressive consolidation to micro-cutting—time to re-examine fiber denier or finish chemistry. For elastomeric pads, thickness loss may be monotonic with little mass change: that indicates viscoelastic compaction rather than abrasive removal, and suggests tuning polymer crosslink density instead of adding hard fillers.

Statistically, model progressive wear with piecewise linear or segmented regression. Place breakpoints at the transitions you see in the curves, not at arbitrary cycle counts. Report confidence intervals for each segment’s slope. For failure events, use Kaplan-Meier survival curves and log-rank tests to compare materials; it’s more honest than cherry-picking “best case” replicates.

Mechanism confirmation matters. Use 50× optical microscopy each pause; annotate where fibrillation, pill formation, or matrix cracking starts. For critical points, capture SEM images at 500×. In many luggage textiles, I’ve seen a clear shift at 12–18k cycles—from binder abrasion within coated yarns to filament pull-out—accompanied by a COF uptick of ~0.1. That’s a signal to change coating chemistry rather than weave pattern.

Finally, translate curves into maintenance or warranty guidance. If 80% of samples drop below 70% thickness retention at 20k cycles, and your field data equate 1,000 cycles to roughly 2 weeks of business travel use, you can set a service interval or spec a reinforcement patch with a replacement threshold grounded in time-resolved data.

Field validation and scaling up

No lab rig perfectly reproduces the field, but you can calibrate. Start with usage profiling: instrument a few products with accelerometers and load cells to estimate contact pressures and sliding distances. For luggage, that might be corner loads during curb drags, handle loads during pulls, and fabric-edge contacts inside overhead bins. Compute distributions rather than single values; median loads and 90th-percentile cycles are both useful.

Next, build a mapping between lab cycles and field time. If an average airport day subjects a bag corner to 200 cm of rubbing at ~10 kPa, and your Wyzenbeek rig delivers 10 cm stroke per cycle at 12 kPa, then 20 field strokes approximate 2 lab cycles after adjusting for pressure using Archard’s law proportionality (wear volume ~ load × distance × k). Validate with small field-return cohorts: measure thickness, fuzz grade, and mass loss, then find the lab cycle count that yields the same indices.

Scale testing with design-of-experiments. Evaluate two loads (9 and 12 kPa), two environments (30% and 65% RH), and two abradants; you’ll capture interaction effects. Reserve a third of your samples for confirmatory tests using the “best” settings. It’s tempting to lock on a single test, but confidence comes from convergence: when Martindale, Wyzenbeek, and Taber rank materials similarly and your field mapping agrees, you can spec with fewer caveats.

Communicate in service language: “At 12 kPa, fabric A retains 75% thickness at 25k cycles; equivalent to ~30 weeks of daily travel. Fabric B retains 62%—a 20% reduction in loading resistance over the same time.” That frames trade-offs clearly for stakeholders. And keep version control on test rigs—abrupt shifts in results often trace to unnoticed abradant batch changes or wheel wear, not the material.

Oscillatory Cylinder Abrasive — Video Guide

If you want to see oscillatory abrasion in action, check out a demonstration of an oscillatory cylinder fabric tester configured to ASTM D4157. The video walks through the Wyzenbeek method: clamping the specimen, setting normal load, selecting abradant, and logging cycles until a defined end point. You’ll see how the fixture creates a repeatable back-and-forth rub that mirrors many real contact geometries, like luggage fabric against seat rails.

Video source: Oscillatory Cylinder Abrasive Machine to measure abrasion resistance for fabric as per ASTM D4157.

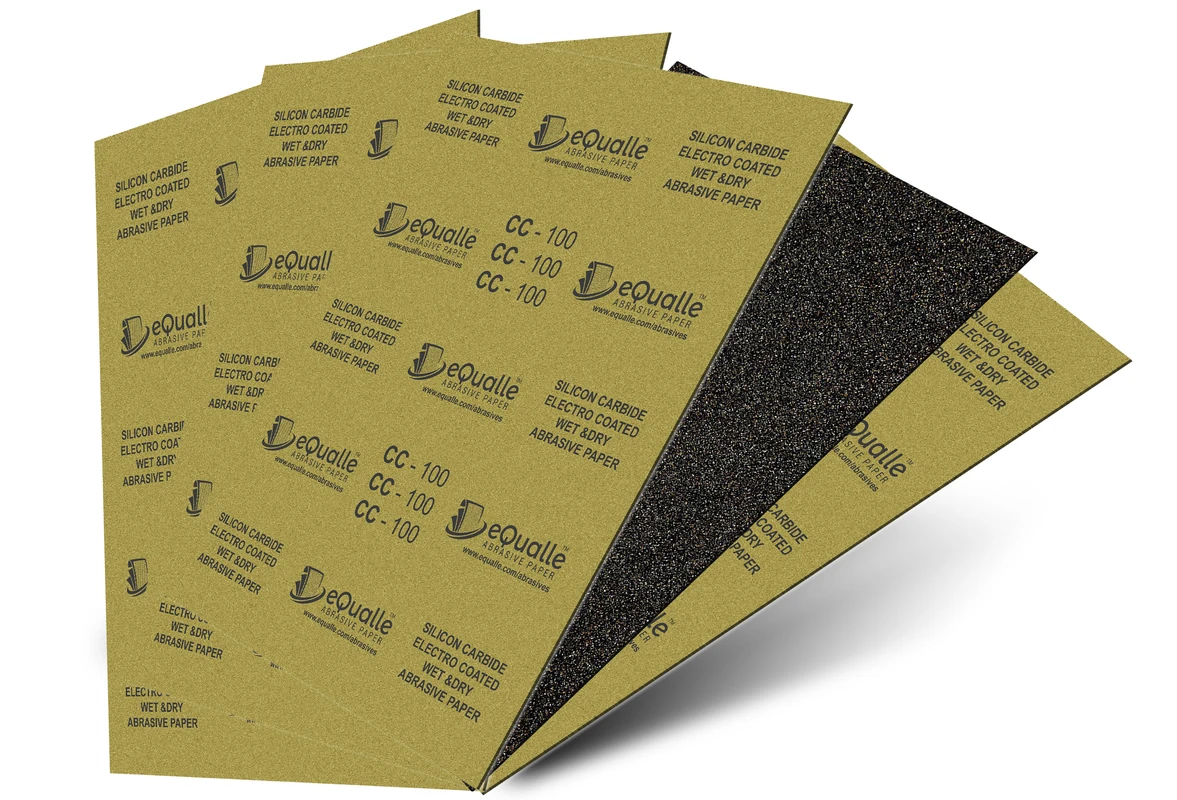

500 Grit Sandpaper Sheets (50-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Fine precision sandpaper for detailed primer and surface smoothing. Removes light scratches and prepares for higher-grit polishing. Suitable for plastic, resin, and metal work in wet or dry conditions. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: What’s the best single test to predict loading resistance over time?

A: There isn’t a universal best test; choose the rig that matches your contact geometry and load. For luggage fabrics, Wyzenbeek often maps better than Martindale; for polymer feet or shells, Taber Abrasion is more indicative. Always supplement with time-resolved metrics (COF, thickness) and field mapping.

Q: How many cycles equal one year of real use?

A: It depends on the product and user profile. Instrument short field studies to estimate daily sliding distance and contact pressure, then map to lab cycles via wear proportionality (wear ~ load × distance × k). Validate the mapping with a small set of field-returned samples to avoid over- or underestimation.

Q: Should I prioritize mass loss, thickness loss, or cycles to break?

A: Track all three if possible. Thickness loss captures compaction and conformal changes, mass loss captures material removal, and cycles to break captures catastrophic failure. Their relationships over time reveal mechanism shifts and provide a fuller picture of loading resistance decay.

Q: How do humidity and temperature affect abrasive testing results?

A: Humidity can plasticize hydrophilic fibers (delaying brittle failure) or increase plowing by softening finishes; temperature from frictional heating can soften polymers or dry lubricants. Control environment (23 ± 2°C, 50 ± 5% RH) and log temperature near the contact to interpret inflections in wear and COF.

Q: What’s an actionable way to reduce late-stage wear spikes?

A: Target mechanism transitions: upgrade finish chemistry to maintain lubrication, increase fiber denier in high-stress yarns, add corner reinforcements with higher crosslink density polymers, or reduce counterface roughness at hardware interfaces. Validate changes with segmented regression on wear curves to confirm slope reductions in late cycles.