How to Swap Detail Sander Sheets Fast and Clean

The moment always arrives at the worst time—on a stubborn corner where paint gathers like drifts of snow, and your sander starts to hiss instead of bite. You glance down: the grit is glazed, the tip is frayed, and your pace stalls. Swapping detail sander sheets should be quick and clean, but if you’re peeling at the edges, misaligning dust holes, or leaving residue on the pad, it becomes the dreaded task that derails flow. Whether you’re reviving an old window sash, smoothing a toy chest lid, or easing a cabinet door into a perfect close, that triangular sheet is the tiny workhorse that makes sharp edges and tight spaces feel easy—if you manage it well.

Maybe you’ve tried to coax one more pass out of a dull sheet and wound up clogging the next grit with dust. Maybe you’ve tugged too hard at the point and lifted foam from the pad. Or maybe grit changes scatter your bench with offcuts, mislabeled sleeves, and mystery holes that don’t line up with your vacuum port. The truth is, replacing triangle sheets cleanly and quickly isn’t just about speed—it’s about preserving the pad, keeping dust under control, and staying on a consistent grit path so the finish looks intentional from start to final touch.

The good news: once you understand the mechanics—hook-and-loop vs. adhesive, hole patterns, pad savers, and how to align by feel—sheet changes become a 15–30 second rhythm that supports your craft rather than interrupting it. In this guide, we’ll walk through the why and how, demystify formats and fit, and share a handful of small, practical habits that add up to big gains in precision and efficiency.

Quick Summary: A clean, fast triangle-sheet change depends on the right format (hook-and-loop, hole pattern), simple alignment habits, pad protection, and a tidy, repeatable workflow.

Why speed and cleanliness matter

Every sanding task has a finish line defined by touch: you can feel proud grain, an even edge break, or a joint that disappears. Getting there efficiently depends on changing abrasives at the right moments—not five minutes late. When you keep changes fast and clean, three things happen immediately:

- You maintain a true grit progression. Jumping from 80 to 220 to “make up time” usually backfires with scratches that reappear under finish.

- You reduce heat and clogging. A dull sheet runs hot and smears resins; swap earlier and your cuts stay crisp.

- You protect the sander’s pad. Wrestling with stuck paper, especially at the tip, can tear foam or weaken hook-and-loop.

Clean changes also improve dust extraction. Triangle sanders are small, but their dust port matters. If holes in the sheet are even slightly off, you reduce airflow and load the abrasive faster. That’s true on raw pine, painted trim, and especially on resinous hardwoods where dust can cake. Proper alignment prolongs sheet life and keeps your workspace clearer—and, more importantly, your lungs safer.

Good timing is another part of cleanliness. If you wait for a sheet to fail visibly, you’ll grind dust into the next grit and contaminate surfaces. Develop a feel: when the cut rate drops and you need more passes to achieve the same result, change. It’s usually sooner than you think. Because triangle tips work hardest, rotate a fresh sheet during use to spread wear, then replace before the tip overheats and curls. Seconds saved in swaps compound across a project, and the end result shows it.

Fit and formats: triangle sheet basics

Triangle sanding sheets come in a few standard sizes and attachment styles, and getting the match right is step one to speedy changes. The most common shape is the “delta” triangle with a long point—often 93 mm or 140 mm on a side—used by many detail sanders. Some manufacturers (like “mouse”-style sanders) use proprietary tips and hole counts, while others accept universal patterns. The wrong fit slows you down: holes don’t align, the tip overhangs and frays, and you spend time trimming or repositioning.

Attachment matters as much as size. Hook-and-loop (often marketed as “Hookit” or “Velcro”) dominates for detail sanders because it’s fast to remove and reapply without solvents. Pressure-sensitive adhesive (PSA) sheets exist and stick firmly, but they require more care to remove cleanly and can leave residue that shortens pad life. For frequent grit changes—shaping, then smoothing in quick succession—hook-and-loop is the hands-down winner.

Hole patterns affect dust control and ease of alignment. You’ll see 6-hole, 8-hole, and multi-hole “universal” designs. More holes can improve dust pickup and make alignment less critical; the multi-hole layouts often move enough air even if you’re off by a millimeter. If your sander connects to a vacuum, choose sheets that match the pad’s pattern or go universal to keep things simple.

Finally, consider accessories that simplify swaps. A thin “pad saver” or interface pad sits between your hook pad and the sheet. It takes the brunt of heat and wear, especially at the tip, and can be replaced cheaply when its hooks tire. It also reduces the risk of tearing pad foam when you remove a sheet—an underrated time-saver when you’re in a groove.

Choosing detail sander sheets for fast swaps

If you want to change abrasives in seconds, start with sheets designed for easy handling and low clogging. High-quality hook-and-loop backers grab firmly yet release without pulling at the foam underneath. Look for stearate coatings and open-coat designs on wood to shed dust and resist loading; on paint and varnish, anti-clog coatings help the sheet cut longer so you’re not swapping every few minutes.

Hole patterns are your friend here. Multi-hole “clean sanding” styles create an airflow map that’s forgiving when you’re working quickly. Even a slight misalignment won’t choke your vac. And because dust leaves the cut zone faster, the sheet runs cooler and lives longer—meaning fewer changes overall. Grit ranges that cover shaping to finish (80, 120, 150, 180, 220, 320) let you keep a compact, consistent set at hand.

If you have a sander with a delicate or pricey pad, invest in pad savers. They add a sacrificial layer of hooks that takes the abuse of frequent changes. The bonus is smoother removal: you can peel the sheet from the pad saver, not the bare foam.

Materials matter too. Ceramic and precision-shaped grains cut faster and maintain sharp edges longer than traditional aluminum oxide, which translates to fewer, cleaner swaps. You’ll feel the difference in drag and hear it in the cut sound—steady, crisp, not squeaky.

According to a article

Practical choices make your station faster: pre-sort sheets by grit in labeled, dust-proof envelopes; keep a small brush to clean hooks between swaps; and choose “universal fit” triangle sheets if you own multiple sanders. That way, you’re never hunting for an exact-hole pattern before you can keep moving.

Clean removal without wrecking the pad

The quickest change is the one that doesn’t damage anything. Pad foam and hook fields are easy to harm with the wrong technique, especially at the triangle’s point where leverage invites tearing. A few simple habits protect your tool and keep changes tidy.

- Power down and wait for a full stop. If you’re using a corded sander, unplug; with cordless, pop the battery if your model allows. It’s safer, and the pad won’t “walk” as you align.

- Peel from the base, not the tip. Start lifting a corner midway along one edge with a thin, smooth plastic scraper or an old loyalty card. Ease the sheet back across the surface to release hooks evenly, then lift the tip last. This prevents point curl and foam lift.

- Clean hooks regularly. Dust trapped in hook fields reduces grip and forces you to press harder to seat a sheet, which makes later removal harder. Use a soft nylon brush or low-pressure air to clear hooks every few changes.

- Use pad savers. They’re inexpensive and take the wear, especially if you swap grits often or work with heat-prone finishes. When hooks on the saver get tired, replace the saver—your main pad stays fresh.

- For PSA users: warm, not hot. If you’re removing adhesive-backed triangles, a few seconds of gentle warmth with a hair dryer softens adhesive without melting foam. Roll the sheet off steadily. Remove residue with a citrus-based adhesive remover sparingly applied to a cloth (never soaked into the pad). Let the pad dry fully before the next sheet.

Lastly, don’t yank. The extra second to lift methodically saves minutes—and the cost of a replacement pad. If you’re working all day, budget one mini clean every hour: peel, brush hooks, wipe dust from the pad face, and seat the next sheet carefully. Your swaps will stay smooth and your cuts more consistent.

Workflow tips to change sheets in seconds

Speed is a system. Set up your bench so changing triangle sheets takes the same small sequence every time—no thinking, no searching. These practical tips keep swaps under 30 seconds while protecting your finish quality.

- Build a grit ladder. Keep 3–5 envelopes or trays labeled 80, 120, 150/180, 220, 320+. Pre-stack two or three sheets in each. As you dull one, peel, clean the hooks with a quick brush stroke, and grab from the next slot. No rummaging.

- Index your alignment. Put a tiny paint dot at one corner of your sander’s pad and a matching dot on each sheet stack. When you apply a sheet, line up the dots first, then feel for hole alignment with gentle pressure. This “index” gets you close enough that multi-hole patterns always work.

- Rotate the tip. Triangle tips wear first. Mid-use, peel the sheet halfway, rotate it 120 degrees, and reseat to present a fresh tip. You’ll double its life and spend less time swapping.

- Keep a hook brush and card ready. Store a soft brush and a plastic card right where you dock the sander. After every change: two brush swipes across the hooks, one across dust holes, then seat the next sheet. It takes five seconds and pays off all day.

- Protect the pad with a saver. If you swap often, a 1–2 mm pad saver is essential. It spreads pressure and resists heat at the tip. When its hooks tire, snap on a new saver—no downtime, no foam repair.

You can further streamline by pairing grit changes with task milestones: shape hardware recesses at 80, refine edges at 120, remove scratch pattern at 180, then smooth to 220/320. As soon as you feel drag increase or see dust loading, change before the sheet overheats. A clean, cool abrasive cuts faster and leaves fewer swirls, so you spend less time revisiting defects down the line.

KraftFix by Einhell — Video Guide

This short product demo showcases an electric detail sander bundled with ten triangular sheets. You’ll see how the hook-and-loop pad lets the sheets snap on and peel off quickly, and how the pointed tip reaches into tight corners without fuss. The presenter moves through grits and contours to highlight how a small sander can handle trim, furniture edges, and craft projects.

Video source: KraftFix by Einhell Electric Detail Sander with 10 Sanding Sheets on QVC

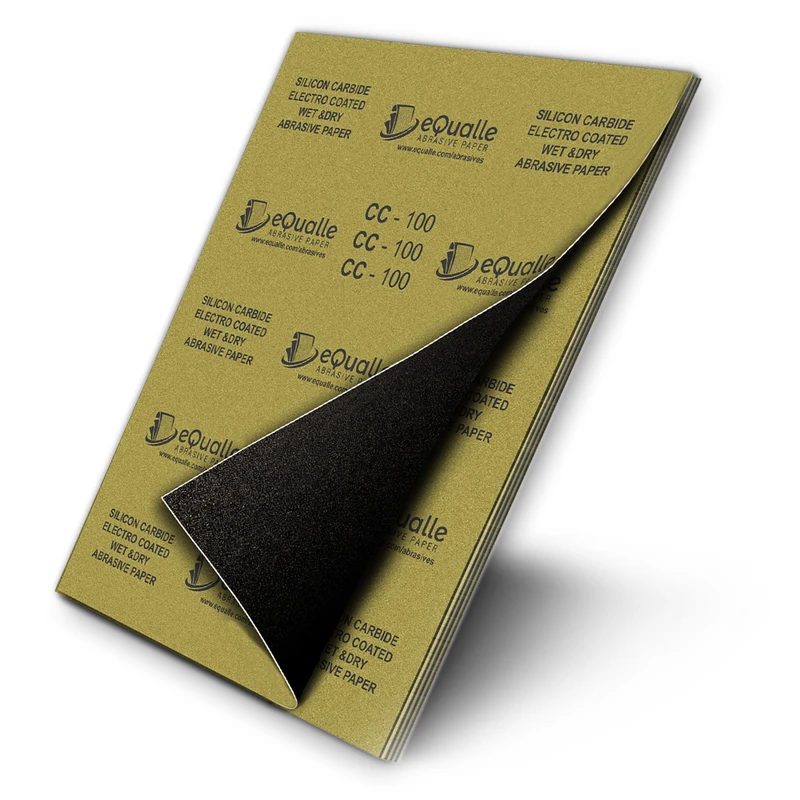

220 Grit Sandpaper Sheets (100-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Fine finishing grit for final surface preparation before painting or coating. Offers uniform cutting on wood, metal, and plastic. Leaves a smooth, paint-ready finish suitable for wet or dry sanding. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: How often should I change a triangular sanding sheet?

A: Change as soon as cut rate drops—typically when you need extra passes to get the same result, or when the sheet looks shiny rather than gritty. On resinous woods and paint, that might be every 5–10 minutes; on clean hardwood with dust extraction, sheets last longer. Rotate the sheet 120 degrees once to extend life before replacing.

Q: Do I need to match the exact hole pattern on my sander?

A: If your sander has a specific pattern and you rely on dust extraction, yes—match it or use multi-hole “universal” sheets that maintain airflow even with slight misalignment. Good dust pickup keeps the abrasive cooler and cleaner, which shortens change time and improves finish.

Q: What’s the best way to avoid damaging the pad when removing sheets?

A: Don’t pull from the tip. Lift a corner along a flat edge with a plastic card, peel across the surface to release hooks evenly, and clean the hook field with a soft brush before the next sheet. Using a thin pad saver adds a protective layer so the sander’s original pad lasts longer.

Q: Should I choose hook-and-loop or adhesive-backed triangles?

A: For most users and frequent grit changes, hook-and-loop is faster and cleaner. PSA (adhesive) sheets can hold very firmly but take longer to remove and can leave residue. If you do use PSA, warm the sheet gently to release and clean any residue with a small amount of citrus-based remover on a cloth.

Q: Can I cut my own triangle sheets from a roll?

A: Yes—if you have a template and a hole-punch guide. Trace your pad, cut cleanly with sharp scissors, and punch holes to match. It’s economical for high-volume work, but ensure the backing matches your pad (hook-and-loop vs. PSA) and that holes align well for dust extraction.