When You Can Skip Grits: A Sandpaper Grit Chart Guide

You’ve cleared a corner of the garage, moved the bikes just enough to set out sawhorses, and wrestled a wobbly dresser onto the stands. It’s late, your playlist is humming, and there’s a small mountain of sanding discs beside you—80, 100, 120, 150, 180, 220, 320. You glance at the packaging diagram, then pull up a sandpaper grit chart on your phone, wondering if you really have to touch every single step. You’re not restoring a museum piece; you just want this dresser to look clean and feel smooth before paint. How many passes will it take? How many hours?

You start at 80 to bite through a stubborn varnish, the sander chattering a little at first until it levels into a rhythm. The wood emerges, pale and promising. But questions keep tugging at your sleeve: If the 80 did its job, can you jump to 120? Will 180 be enough before primer? Do you even need 220 for a painted finish? Time matters—so does the result. And buried in that little mountain of discs is your answer. It’s not about hitting every number; it’s about understanding what each grit does and whether the next one can actually erase the scratches you’ve just made.

The good news: once you grasp how scratch patterns work, skipping grits becomes a confident choice, not a gamble. There are safe shortcuts you can take, and moments when skipping will cost you more time later. By the end of this guide, you’ll know how to read a chart, read the wood, and read your results—so you can get to a flawless surface faster, without the guesswork.

Quick Summary: You can safely skip intermediate grits when the next grit can remove the previous scratches efficiently—usually skipping one step on sound surfaces, with fresh abrasives, reliable dust extraction, and clear inspection under good light.

Why grit steps matter

Every pass with sandpaper is a controlled scratch. Coarser grits cut deep and fast, leveling highs and removing coatings. Finer grits don’t level; they refine. The magic of a clean finish lives in the handoff between these two: the moment when the next grit can erase the previous scratches without spending ages doing it. That’s why grit steps matter more than counting discs—they’re about scratch depth and scratch spacing.

Two things shape that scratch pattern: the grit size and the abrasive system. FEPA P-grades (P80, P120, P180, etc.) used on most modern discs follow a predictable grain size progression. Abrasive type (aluminum oxide, ceramic, silicon carbide), the backing, and your tool’s motion (random-orbit vs. hand-sanding with the grain) also influence how those scratches sit in the surface. Random-orbit patterns tend to be shallow but multi-directional; hand-sanding aligns scratches with the grain, which the eye forgives more easily.

Why not jump straight from 80 to 220? Because 220 isn’t designed to plow out the trenches that 80 leaves behind. It can do it eventually—but “eventually” may mean expensive paper, heat buildup, and swirl marks that reveal themselves only after stain or topcoat. Conversely, hitting every single grit wastes time if the previous step already reduced scratch depth enough.

A practical rule emerges: change grits when you’ve fully removed the prior scratches—no sooner, no later. That means inspecting under raking light, using pencil guide marks, and stopping as soon as the marks disappear evenly. In the coarse and medium stages (80 through 150/180), you can sometimes skip a step if your scratch pattern is clean and your surface is cooperative. Above 220, especially for clear finishes, smaller jumps protect clarity and uniform sheen.

When skipping grits is safe

Skipping grits is about context: material, finish goal, tool, and abrasive condition. On bare, flat hardwood with a random-orbit sander and quality P-grade abrasives, you can often skip one intermediate step in the early progression. For example, after leveling with P80, a jump to P120 is reasonable if the P80 pass left a uniform scratch and you used dust extraction. From there, P180 can set you up for paint, or P220 for stain on open-grain species.

Here are scenarios where skipping is usually safe:

- After thorough coating removal with P80 or P100, jumping to P120 or P150 works if your P80 pass is clean (no deep grooves or pigtails) and you vacuum between steps.

- For painted finishes, a sequence like P80 → P120 → P180 often suffices, skipping P100 and P150. Paint fills micro-scratches and will be scuff-sanded before coats anyway.

- On dense hardwoods where the surface is already flat (e.g., factory-planed panels with minimal tear-out), you can start at P120 and go to P180 or P220 directly.

Moments to avoid skipping:

- When you see tear-out, deep dents, or random-orbit pigtails: those defects need the immediate next grit to remove efficiently.

- Above P220 if you plan a clear finish: larger jumps risk uneven sheen and visible scratch ghosts after finish cures.

- With worn discs: dull paper doesn’t cut cleanly, leaving erratic scratches that are harder for the next grit to erase.

Think in terms of “workload per grit.” The next grit should erase the previous scratches in a short, controlled pass. If you find yourself leaning harder, generating heat, or spending more than a couple minutes per square foot, you skipped too far. Back up one grit, clean up the scratches quickly, then advance again. Taking that tiny step back once saves multiple steps forward.

Reading a sandpaper grit chart in practice

A sandpaper grit chart is a map, not a mandate. It shows grain sizes and suggests common use ranges: coarse (P40–P80) for removal and leveling, medium (P100–P150/180) for refining shape and prepping for primer or paint, and fine (P180–P320+) for stain readiness and between-coat smoothing. But the right “route” depends on where you start and how you drive.

For bare wood, a pragmatic baseline looks like this:

- Heavy leveling or finish removal: P80 → P120 → P180 (paint) or P220 (stain)

- Lightly milled stock with minor mill marks: P120 → P180 → P220

- For clear, high-clarity finishes: add P320 before pore filling or sealer on hard, closed-grain woods

For previously painted pieces you’ll repaint, grit selection is more forgiving. Scuff with P180 to P220 after cleaning and deglossing; only drop to P80–P100 where you need to feather chipped edges. For metal, silicon carbide or ceramic in P120–P220 refines edges before primer; avoid loading by using stearated or wet/dry papers and keep jumps conservative to control visible scratch patterns under gloss.

Jump sizes matter. As a general guide, “skip one” within families is usually efficient (e.g., 80 → 120 → 180). Bigger jumps force the finer grit to “level” rather than refine, which wastes time and encourages swirl. According to a article, many finishers cap skipping at one step, especially as they approach finish-ready surfaces. The closer you get to topcoat, the smaller your moves should be.

Finally, FEPA P-grades differ from CAMI numbers on older sheets. Stick to one standard within a project; P220 isn’t identical to 220 CAMI, and mixing can throw off your expectations. If you must mix, do test patches and trust your inspection lighting rather than the label.

Common pitfalls and fixes

Even with a smart progression, a few traps can derail results—especially when you skip. Recognizing them early is the difference between a quick correction and a full do-over.

- Pigtails and swirls: Tiny spirals from a random-orbit sander signal a trapped particle, loaded disc, or too much pressure. Don’t jump ahead hoping they’ll vanish; they telegraph through stain and glossy paint. Fix by stepping back one grit, replacing the disc, and sanding with light, even pressure while the sander runs before touching down and lifts off while running.

- Cross-grain scratches: Hand-sanding across the grain or catching end grain with a coarse grit leaves scratches that later grits struggle to hide. Always finish by hand with the grain at your final grit, especially on edges and profiles, to align micro-scratches with what the eye forgives.

- Loading and heat: Resinous woods, paint, and soft materials clog paper fast. A loaded disc stops cutting, starts polishing, then burns. If heat rises or dust cakes, you’re not ready to skip; clean or replace the disc, use dust extraction, and consider stearated papers or lower speed.

- Shadow scratches after finish: The heartbreak of seeing “ghosts” after your first coat usually means you skipped too far near the end. Strip? Not necessarily. Scuff-sand the finish when cured with the correct grit (often P320–P400), spot-correct the substrate if needed, and recoat. If the ghosts originate at P120–P180, you may need to sand back to bare and climb the ladder more carefully.

- Uneven sheen on stained surfaces: This indicates varying scratch depths or patches that didn’t reach the same final grit. Use raking light and a pencil scribble grid to ensure each pass fully erases the previous stage across the entire surface before skipping.

Keep an audit mindset: each grit should do a specific job, and you “sign off” on that job before moving on. If you can’t confirm under good light, don’t skip. Two extra minutes of inspection saves an hour of correction later.

Pro tips for faster, cleaner sanding

Speed comes from control, not aggression. These practical tips help you skip smartly while protecting the finish.

- Use pencil grids: Lightly scribble a crosshatch over the surface. Sand until the marks disappear uniformly. If isolated marks linger, address those before you jump a grit. This keeps each step honest and short.

- Work under raking light: Set a bright lamp low to the surface. Shadows reveal scratches and swirls that overhead lights hide. Inspect before and after each grit; if you see uniform, fine scratches only, you can often skip one step.

- Keep discs fresh and dust extracted: A tired disc cuts poorly and leaves random scratches that force you backward. Vacuum between grits, clean the pad, and change discs at the first sign of heat or loading.

- Match pad firmness to the task: A hard or medium pad levels quickly; a soft interface pad conforms to curves but can round edges. Don’t skip on profiles without switching to a softer interface and hand-finishing the final grit with the grain.

- Wet the grain strategically: For water-based finishes, raise the grain lightly with a damp cloth after P180 or P220, let dry, then knock back the fuzz with P220–P320. This preempts roughness and lets you skip a post-sealer sanding step.

Bonus thought: think in “sets.” For many projects, you’ll use a three-grit set that fits your goal—80/120/180 for paint, 120/180/220 for stain, and 180/220/320 for high-clarity finishes on tight-grain stock. You can often skip within the set if the surface cooperates, but resist the urge to mix sets impulsively.

How Do I — Video Guide

If you’re new to furniture flips or just want a clear walkthrough, this concise video breaks down which grit to use at each stage and how to move from removal to finish-ready surfaces. It walks you through prepping old finishes, choosing starting and ending grits, and the logic behind each jump so you avoid time-wasting steps.

Video source: How Do I Sand Furniture? | Sandpaper Grit 101 - Know Which Grit to Use for Each Step of Your Flip!

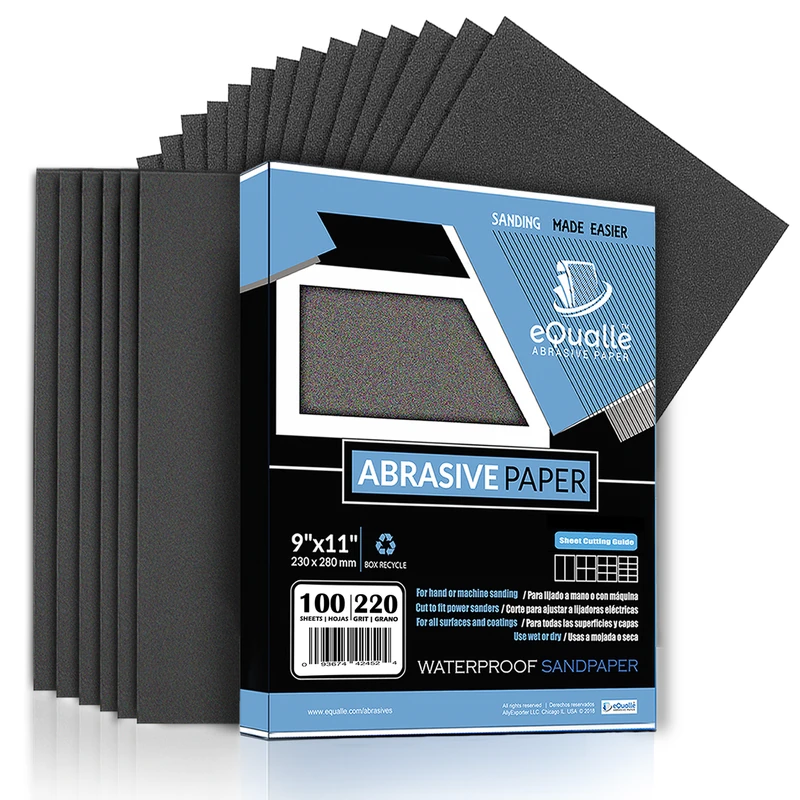

180 Grit Sandpaper Sheets (50-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Medium finishing grit that refines wood, metal, or drywall before painting. Provides even texture and cutting control. Excellent for wet or dry sanding where a uniform surface is needed. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: What’s a safe rule for skipping grits on wood?

A: In the coarse-to-medium range (P80–P150/180), you can often skip one step if your scratch pattern is uniform and you use dust extraction. Above P220, especially for stain or clear coats, avoid skipping; smaller jumps protect clarity.

Q: Can I go from P80 straight to P180?

A: It’s possible but usually inefficient. P180 is designed to refine, not level. You’ll spend more time and risk swirls. A better path is P80 → P120 → P180, or P80 → P150 if your P80 pass was very clean and the surface is flat.

Q: Do I need to sand to P320 before painting?

A: Not typically. For most primers and paints, P180–P220 is ideal. Higher grits can reduce adhesion. Reserve P320+ for clear finishes, between coats, or for very tight-grain species where sheen uniformity matters.

Q: How do I know if I skipped too far?

A: If the next grit struggles to remove the previous scratches (you’re pushing harder, generating heat, or sanding more than a couple minutes per square foot), you likely jumped too far. Step back one grit, clean the surface, and proceed.

Q: Should I mix FEPA P-grades with non-P papers?

A: It’s best to stick to one grading system per project. FEPA P220 doesn’t exactly match CAMI 220. If mixing is unavoidable, rely on raking light and test areas to judge progress rather than the printed number.