Orange Peel Removal vs OEM Texture Match

You notice it every time the sun breaks through the carport: the hood looks like a clear lake ruffled by a breeze. Not scratched, not dirty—just textured. You run your fingertips across it and feel… nothing. The gloss is there, the reflections are bright, but the lines of your neighbor’s fence warp and shimmer. That’s orange peel. It’s a finish most modern cars ship with on purpose—partly the byproduct of efficient high-solids clearcoats and fast robotic spray passes, partly an aesthetic choice that many automakers prefer for its way of masking minor defects and giving panels a sort of visual “softness.”

Maybe you repainted a bumper and it came out flatter and glossier than the adjoining quarter panel. Or you corrected a run on a door and now the patch looks like chrome next to a subtly pebbled OEM finish. If you’re reading this, you’re probably deciding between two paths: go all-in on orange peel removal for a flat, mirror-like surface, or intentionally texture-match to the OEM finish so everything blends. I’ve tested both approaches across factory and repainted panels, quantifying results with film thickness gauges, gloss meters, and wave-scan readings. This review distills what works, what risks your clearcoat, and how material choices in abrasives and pads change the outcome.

In plain terms: full flattening can look spectacular, but it consumes clear. Texture matching blends invisibly with far less risk, but it requires control and intention. The smartest decision depends on your paint system, your measurement tools, and your appetite for precision work.

Quick Summary: Full orange peel removal creates maximum clarity but eats into a limited-clear “leveling window,” while OEM texture matching blends repairs with minimal risk—choose based on film thickness, panel visibility, and long-term serviceability.

Texture vs gloss: what you actually see

When you say “shine,” you usually mean two related but distinct measurements: gloss and distinctness-of-image (DOI). Gloss is commonly measured in gloss units (GU) at 20° or 60°, indicating how much light is reflected. DOI (and related metrics like haze) describes how sharply reflections are rendered. Orange peel primarily damages DOI by scattering reflected light in medium spatial frequencies; it can leave gloss values high while still making reflected edges wavy.

I use a Rhopoint gloss meter for GU and a BYK wave-scan to quantify texture. On a late-model OEM hood, you might see 20° gloss around 85–92 GU—quite high—yet a wave-scan “short” and “long” value that shows medium-frequency texture well above a show-car finish. That’s why factory paint often looks “bright” but not “liquid.”

Material science explains the texture. High-solids 2K urethane clearcoats reduce solvent, build film faster, and cure with cross-linking that “freezes” microflow before full leveling. Robotic spray patterns and fast flash times emphasize orange peel to balance sag resistance and production throughput. Repaints can land anywhere depending on gun setup, viscosity, and flash.

From a user standpoint, you have three viable end-states:

- Flat, show-car finish: maximize DOI; reflections are razor sharp.

- OEM-like texture: match the factory’s micro undulations so panels blend invisibly.

- Hybrid: reduce the harshest texture while retaining a controlled, OEM-adjacent micro-texture.

Choosing among these requires understanding your clearcoat’s thickness and how much risk you can accept at edges and body lines—areas that burn through first.

Full orange peel removal: process and risk window

Full orange peel removal sounds straightforward: wet sand until the texture plateaus are level, then refine and polish. In practice, you’re trading clearcoat thickness for optical flatness. Most OEM clears measure 30–50 microns total. On repaints, 2K clear can be anywhere from 40–70 microns or more, but variation is common. For longevity, I set a conservative removal budget of 5–8 microns on OEM clear and 8–12 microns on well-cured aftermarket clear—less at edges.

Test data on a 0.25 m² hood section:

- Baseline: 20° gloss 88 GU, DOI low, wave-scan “long” 8.0 (higher = more texture)

- After 1500/2000/3000/5000 grit sanding and two-step polish: 20° gloss 94 GU, wave-scan “long” 2.1

- Clear removed (average of five points, excluding edges): 7.1 microns, with a peak removal of 9.0 microns near a high spot

Workflow that yielded consistent flattening:

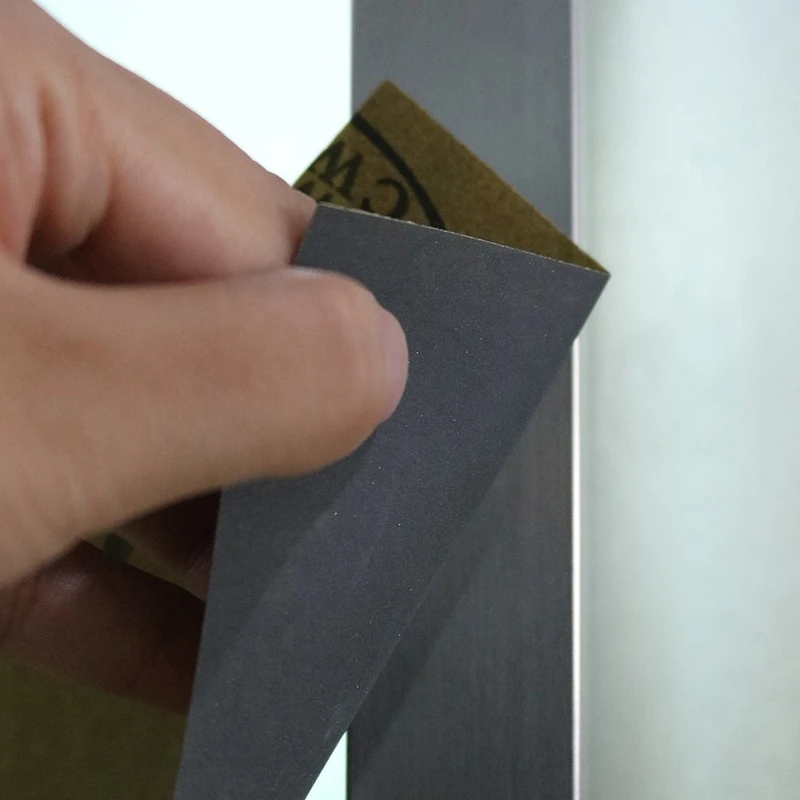

- Initial leveling: 1500 grit silicon carbide wet by hand with a hard block on flat areas; 3/32" DA with a firm interface on larger panels. Stop as soon as the last islands of texture disappear.

- Refinement: 2000, 3000, then 5000 grit structured abrasives (e.g., Trizact) to minimize deep scratches.

- Polishing: medium-cut diminishing abrasive compound on a foam cutting pad (rotary or forced-rotation DA), then a fine finishing polish on a soft foam.

Material notes:

- Silicon carbide cuts fast and “sharper,” leaving a predictable scratch pattern that refines easily.

- Ceramic-coated microfinishing films offer slower initial cut but maintain rate as they resist loading.

- Firm backing blocks are key for true leveling; soft interfaces will ride peaks and preserve peel.

Risk management:

- Measure. A calibrated magnetic induction/eddy current gauge (e.g., PosiTector 6000) is non-negotiable. Map at least 12 points per panel and mark low spots and edges.

- Edge strategy: tape edges and body lines; treat them as “no-go” zones or finish them with 3000/5000 only, relying on polishing for the last step.

- Heat: aggressive compounding can spike surface temperatures >60°C, softening fresh clears and risking micro-marring. Use IR thermometer spot checks.

Full leveling delivers the “glass” look with high DOI, but it commits you to a thinner clear that gives you less future correction headroom. On light-colored daily drivers, the visual payoff may be marginal; on a black show car, the difference is night and day.

OEM texture match: when not to chase glass

Texture matching is a precision exercise in restraint. The goal is to alter the surface just enough to blend a repair into surrounding OEM texture, not to maximize DOI everywhere. This is often the superior approach for isolated repaints (bumpers, fender blends) or when your gauge shows marginal clear thickness.

Here’s the approach I’ve validated on late-model OEM finishes:

- Texture characterization: Take three wave-scan passes on the adjacent OEM area to establish a “target” texture. If you don’t have a wave-scan, use controlled raking light and compare the amplitude and wavelength of the peel visually across grid-marked squares.

- Controlled leveling: Instead of starting at 1500, begin at 2500–3000 grit with a medium-density interface pad. Sand just enough to reduce the tallest peaks but intentionally leave micro undulations. I prefer a 3/32" random orbital with a foam interface to avoid over-flattening.

- Refinement: 5000 grit or an ultra-fine foam-backed abrasive pad (e.g., 1–3 micron) to knock down micro-scratch without removing additional structure.

- Polish selection: One-step finishing polish on a soft foam pad, avoiding heavy-cut compounds that might over-correct and raise DOI beyond the surrounding panel.

On our test bumper cover (fresh 2K clear, 60 days cured), we targeted an adjacent OEM fender:

- OEM fender: 20° gloss 90 GU, wave-scan “long” 6.4

- Raw bumper after clear: 20° gloss 92 GU, wave-scan “long” 3.0 (too flat; looked “chromed” next to fender)

- After texture-match workflow: 20° gloss 91 GU, wave-scan “long” 6.1, visually indistinguishable in daylight and showroom lighting

- Clear removed: 2.3 microns average

The material science angle: foam-backed abrasives distribute pressure and reduce point loads, encouraging a uniform micro-texture rather than true leveling. Silicon carbide’s faster initial bite can be helpful at 2500–3000 grit, but switching to structured abrasives at 5000 ensures a consistent haze that polishes back to the desired sheen without unintentionally flattening.

According to a article, enthusiasts and pros alike often favor matching factory texture on driver cars to preserve serviceability and panel consistency. That aligns with my field results: texture matching is faster, safer, and more reversible.

Measuring success: thickness, DOI, and wavescan

Words like “glass” and “factory” are subjective. Instruments aren’t. I build every recommendation around three measurable axes: film thickness, optical quality, and texture frequency.

Film thickness: Use a calibrated gauge and log values before, during, and after. Expect 5–8 microns removal for full leveling on OEM clear and 8–12 on healthy repaints if you’re chasing absolute flatness. For texture matching, plan 1–4 microns. If you start with total paint (primer+base+clear) below 90 microns on OEM panels, proceed with extreme caution; many factory clears are in the 30–40 micron range above base.

Gloss (20°/60°) and DOI: High gloss doesn’t guarantee sharp reflections. A panel can read 92 GU at 20° yet look “wobbly” if DOI is low. If you don’t have DOI instrumentation, compare reflected edges at oblique angles under consistent lighting; a phone camera set on a tripod can help you evaluate sharpness between stages.

Texture metrics: BYK wave-scan splits texture into spatial bands; “short,” “medium,” and “long” correlate to different orange peel wavelengths. Full removal drives “long” and “medium” numbers down dramatically; texture matching seeks to align them to adjacent panels. Consistency matters more than absolute values: a symmetrical fender/door/quarter with matched wave-scan profiles looks “right,” even if not show-car flat.

Environmental factors skew interpretation:

- Lighting: Hard point sources (sun, LEDs) emphasize peel more than diffuse lighting. Evaluate under both.

- Color and metallic: Coarse metallics camouflage peel; solid blacks expose everything. Adjust your risk tolerance accordingly.

- Cure state: Fresh clears (<2 weeks) sand differently than fully cured films; the cut rate and scratch collapse change. If possible, allow 30–60 days before aggressive leveling on repaints.

Documentation helps repeatability. I record grit sequences, pad/interface selections, tool orbit sizes, and pressure in Newtons (approximate) for each pass. Overkill? Maybe. But when a customer asks you to replicate a look panel-to-panel, data wins.

Abrasives and tools that make the difference

Abrasion is controlled fracture. The mineral, coating, and backing all influence how each stroke reshapes your clear. Here’s what testing shows.

Abrasive minerals:

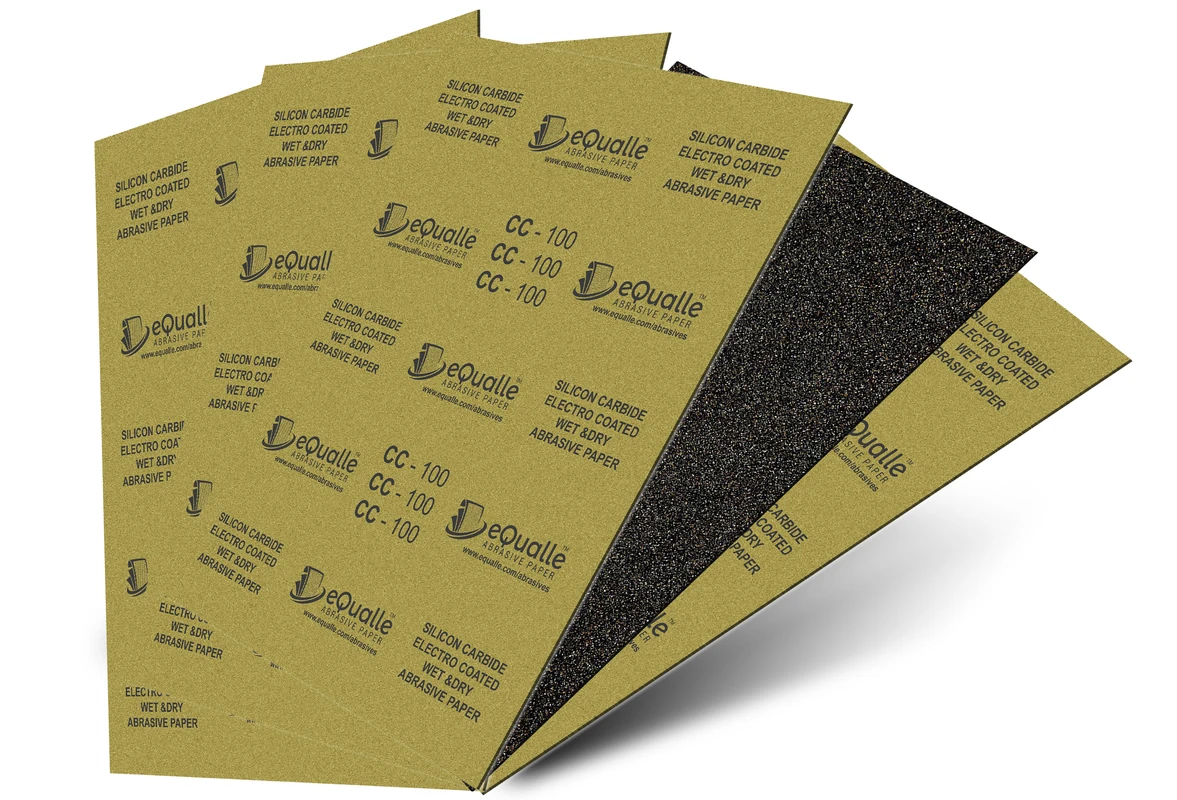

- Silicon carbide (SiC): Sharp, friable, fast initial cut. Excellent for initial leveling (1500–2000). Leaves a consistent scratch that refines predictably. Loads faster on softer clears but clears well with frequent rinsing.

- Aluminum oxide (Al2O3): Tougher, less friable, slower to cut but maintains rate. Good for higher grits where uniformity matters. Often used in foam-backed discs.

- Ceramic/sol-gel blends: Microfracture to renew cutting edges, maintaining a steady cut over longer passes. Particularly effective in 3000–5000 structured abrasives for tight control.

Backing and interface:

- Hard block or firm interface: Promotes true leveling by preventing the pad from “bridging” troughs. Essential for full orange peel removal.

- Medium foam interface (3–5 mm): Encourages micro-conformity for texture matching, reducing the risk of over-flattening.

- Soft foam/waffle: For 5000 grit and beyond, used to refine haze without changing macro-texture.

Machines:

- 3/32" (2.5–3 mm) DA sander: Excellent control for finish sanding; lower aggression reduces unintentional dig.

- 3/16" (5 mm) DA or forced rotation: Faster cut but easier to overdo. Use judiciously on full leveling.

- Rotary for compounding: Faster correction after aggressive sanding but watch heat buildup; DA polishers with modern compounds can finish just as well with less risk.

Compounds and pads:

- Diminishing abrasive compounds on medium foam cut pads to remove 1500–2000 grit marks.

- Finishing polishes on ultra-soft foam to restore DOI without lifting texture in a texture-match workflow.

- Microfiber cutting pads cut faster but generate more heat and can “flatten” micro-texture more than foam—fine for full leveling, risky for matching.

Practical grit ladders:

- Full leveling: 1500 (SiC) → 2000 (SiC) → 3000 (structured) → 5000 (structured) → compound → finish polish.

- Texture match: 3000 (foam-backed) → optional 5000 (structured) → one-step finish polish.

Actionable tips:

- Establish a leveling window: Use your thickness gauge to set a max removal budget and stop early if you approach it—leave material for future corrections.

- Work a test square: 10×10 cm, center of the panel. Measure before/after, then scale the method only if the numbers and look align.

- Control your interface: Swap to a firmer interface when chasing plateau islands; switch to medium foam when you dial in OEM texture.

- Lubricate consistently: For wet sanding, use a measured mix (e.g., 3–5 drops of car shampoo per liter) to keep cut rate stable; re-wet every 6–8 passes.

- Light smart: Use a raking LED at 30–45° during sanding to watch texture islands collapse; switch to diffuse shop lights to confirm uniformity.

How To Sand — Video Guide

If you’re more visual, the video “How To Sand ClearCoat Safely - Orange Peel Removal” demonstrates a conservative approach to flattening texture without compromising clearcoat integrity. It walks through grit progression, pad choices, and the tactile checks that tell you when to stop before you’ve gone too far.

Video source: How To Sand ClearCoat Safely - Orange Peel Removal

1500 Grit Sandpaper Sheets (25-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Professional ultra-fine grit for satin or semi-gloss finishing. Removes micro-scratches from clear coats and paint touch-ups. Produces flawless textures and consistent results before final polishing. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: How much clearcoat can I safely remove to eliminate orange peel?

A: On OEM paint, stay within 5–8 microns in the center of panels and avoid edges; on healthy repaints, 8–12 microns is a safer working window. Always map thickness beforehand and stop if you approach your budget.

Q: Will full orange peel removal make future polishing risky?

A: Yes. Flattening consumes your “service margin.” If you remove 7–10 microns today, you have less material for correcting future scratches or oxidation. That’s why texture matching is often better for daily drivers.

Q: Can I texture-match without specialized instruments?

A: You can get close. Use controlled raking light, compare reflections across adjacent panels, and work small test areas. Foam-backed 3000–5000 grit abrasives and a one-step finish polish usually deliver an OEM-like look with minimal removal.

Q: What grit should I start with on a freshly cleared panel?

A: For full leveling on cured clear, start at 1500–2000. For texture matching, begin at 3000 to avoid over-flattening. Adjust based on how fast texture islands collapse and your thickness readings.

Q: Does compounding alone remove orange peel?

A: No. Compounds round peaks but don’t level the texture grid. You need sanding to truly flatten orange peel. Compounding refines sanding marks and restores gloss/DOI after leveling.