How to Avoid Rounding Edges with Detail Sander Sheets

A crisp edge is honesty you can feel. You run a fingertip along the rail of a cabinet door or the rim of a keepsake box and know immediately whether the prep was careful or hurried. The line should be true—straight, sharp, and confident—not washed out by a power sander that wobbled a hair too long at the corner. The irony is familiar: we reach for a small triangular sander to finesse tight spaces, then watch it soften what we wanted to preserve. If you’ve ever started a job with a fresh pack of detail sander sheets, only to end it with unintentionally eased profiles, this guide is for you.

Edge rounding happens fast—sometimes in a single careless pass—because detail sanders concentrate pressure and vibration at edges and points. The fix isn’t to stop using them; it’s to understand how abrasive geometry, backing stiffness, dust control, and workflow interact at the boundary between flat and void. With a tuned setup and deliberate motion, you can use power to speed the flats while safeguarding the line.

I’ve tested paper and film abrasives across species from poplar to white oak, both raw and sealed, and the pattern is consistent: sheets, pads, and pressure determine whether you cut the face or fold the edge. The techniques below focus on three pillars—surface preparation, abrasive performance, and sanding workflows—so you can move quickly without sacrificing crispness. We’ll cover how to pick the right sheets, how to stage workholding to shield edges, and how to sequence strokes to remove scratches without eroding geometry. By the end, your edges will look like they were knifed, not melted.

Quick Summary: Control pad stiffness, abrasive cut, stroke path, and workholding to keep the sander flat on faces and off edges, preserving crisp geometry.

Why Edges Get Rounded During Sanding

The physics are simple: edges are stress concentrators. On a vibrating triangular pad, the foam interface compresses more at an edge and most at a corner, tipping the abrasive into the arris. With even modest downforce, the effective contact area shrinks while unit pressure skyrockets, accelerating cut right where you least want it.

Three mechanisms compound to dull an edge:

- Pad compliance and leverage: Hook-and-loop pads sit on a thin foam layer. At an edge, that foam collapses, and the platen pivots. The apex of the triangle acts like a lever arm, shifting load toward the edge and magnifying removal.

- Grit behavior and wear: As sheets dull, friable grains fracture less and start to plow instead of cut. Plowing generates heat, the foam softens slightly, and the sheet rides high on the edge like a sled runner.

- Dust packing: Without active extraction, dust accumulates at the edge, forming a slurry that cuts unpredictably. On open-pore woods, that slurry also darkens early and tempts you to “clean up” by lingering longer—exactly the dwell that rounds.

Frequency and amplitude matter, too. Detail sanders (delta sanders, mouse sanders) generally oscillate small amplitudes. If the sheet overhangs the pad or loses adhesion at the tip, that free lip will chatter, scuffing the arris as you cross it. Even the scratch pattern orientation can bias rounding: diagonal strokes that intersect both faces near the edge carry more abrasive across the break.

The net is this: when you let the sander decide the geometry, the edge loses. To prevent rounding, the workflow must constrain pad attitude, reduce foam compliance at the boundary, maintain sharp grit cutting, and keep dust evacuated. The following sections convert that principle into control over sheet selection, support, and stroke.

Choosing detail sander sheets for control

Abrasive choice is your first edge-protection device. The right detail sander sheets cut cooler, track flatter, and resist edge-collapse. That starts with backing stiffness: film-backed abrasives (typically 3–5 mil polyester) stay flat at the pad perimeter, while C/D-weight paper flexes and telegraphs foam compression. On delicate edges, film-backed sheets deliver a narrower and more predictable contact patch, translating into easier control.

Grit and grain matter for surface integrity. For raw hardwoods, start no coarser than P120 on faces that run to an exposed edge unless you have mill marks to remove, in which case limit P80 strictly to open flats and stop short of the arris by 2–3 mm. Use sharp, consistent grain (aluminum oxide for general work; ceramic for aggressive face leveling; silicon carbide for between-coats on finishes). Premium sheets with anti-loading stearate coatings maintain cut longer and avoid heat-glazing that softens foam and overcuts edges.

Hole patterns aren’t cosmetic. With delta pads, align extraction holes precisely; a misaligned sheet shifts suction and increases dust packing at the edge. If your sander supports mesh-style sheets, they can help extraction but are more compliant; mitigate by adding a thin hard platen interface to stiffen the pad.

Two more selection tactics keep edges crisp:

- Avoid thick foam interface pads during edge-critical passes. They’re useful on contoured profiles but will round flats-to-void transitions.

- Ensure the sheet does not overhang the pad at the triangle tip or sides. Trim precisely; any flap will whip the edge.

According to a article, tactile feedback is limited with power detail sanders; your abrasive system must provide the control you can’t feel. In practice, that means retiring sheets early, especially near edges. If you push a dull P180 sheet to “just finish the corner,” you’ll burnish and round. Replace the sheet or transition to a hard block for the last two passes.

Finally, consider PSA (pressure-sensitive adhesive) delta sheets on a rigid accessory platen if your tool supports it. Removing hook-and-loop compliance further reduces tip-rock at edges. Keep a log of which sheet families track flattest on your pad; consistency across brands varies more than grit labels suggest.

Workholding and Edge Protection

Even perfect sheets cannot rescue a setup that leaves the edge exposed to leverage. Workholding that physically blocks the sander from tipping into the arris is the fastest way to prevent rounding while maintaining speed on the flats.

Start with sacrificial fences: clamp a dead-straight, flat batten flush to the edge you want to preserve. The batten becomes a height stop; the sander rides its face, and the pad can’t tilt into the void. For interior edges (like inside a frame), use an L-shaped auxiliary fence or a pair of parallel battens to create a ledge on both sides, distributing pressure and eliminating the “diving board” effect at the pad tip.

Painter’s tape is more than masking. Two layers of high-quality tape along the arris create a micro-shoulder that increases friction at the edge and signals contact before cut. On fragile veneers, pair tape with a scribed knife line: the scribe defines a hard boundary; any accidental cross-grain scratch breaks into the scribe instead of creeping across the face.

For small work, the blue-tape-and-CA trick shines: tape the bench and the workpiece, then bond the tapes with medium CA glue. The part won’t creep under vibration, so you don’t overcompensate with pressure—an easy path to rounding. Use dense foam or cork pads only away from edges; at the edge, support directly under the face with a rigid backer.

Field-proven tips:

- Clamp a 3–5 mm MDF shim flush with the edge; sand the face proud of the shim and plane/scrape the final 0.1 mm. This removes sanding from the edge entirely.

- For profiled moldings, 3D-print or carve a negative-profile block that supports the fillet while you sand the field; the fillet shoulder protects the sharp line.

- On interior corners, slip in a 1–2 mm brass ruler as a hard stop; the sander pad butts it before the triangle point can erode the corner.

- Build a “no-tip” sled: a plywood base wider than the work with two rails acting as outriggers; the sander rides on three points and stays flat at the edge.

- Use bench dogs and a planing stop to work “off the edge” so strokes end just shy of the arris; never start or stop the sander on the edge.

These measures transform edge care from wishful control to physical constraint. When the geometry forbids tipping, your hands can focus on stroke and sequencing instead of guarding against a millisecond of inattention.

Sanding Strokes, Sequence, and Pressure

The cleanest edges come from disciplined stroke geometry and grit progression. Your goal is to remove defects on the face while keeping stroke vectors parallel to the edge and the pad flat through the pass.

Sequence the job so the sander never has to “reach” into an edge:

- Flatten the broad faces first with the detail sander on a hard pad, stopping short of the edge by 2–3 mm if starting at P80–P120.

- Switch to hand sanding with a hard block (MDF, acrylic, or a precision aluminum block) for the last two grits that touch the edge. Use fresh film-backed strips wrapped tight—no cushion.

- Reintroduce the detail sander at higher grits (P180–P220) only if the pad remains fully supported and you can keep it 100% flat.

Stroke mechanics matter. Keep the pad moving before you power on, and lift off while still in motion to avoid dwell at the end of a pass. Orient strokes with the long axis of the triangle parallel to the edge; this maximizes the flat area in contact and minimizes the tip’s leverage. Never “feather” the edge by pivoting the pad—if you need to break the arris, do it intentionally with a block and two passes.

Pressure is where rounding hides. Use just enough downforce to maintain positive contact—typically the weight of your hand plus the tool, calibrated so the motor doesn’t bog and the oscillation stays free. If you feel warmth at the edge or see dust smearing, you’re pressing too hard or dwelling too long. Count strokes: two to three passes per grit per area, overlapping by one pad-width, is sufficient for most hardwoods if your prior grit did its job. Chasing a single scratch near the edge with the sander is a rounding trap; spot-fix with a block instead.

Finally, keep grit jumps modest (P80→P120→P150→P180→P220), and don’t skip the block-wrap step at the edge. A quick water wipe or denatured alcohol raise can help identify scratches before finish, but re-sand only the face zones—not the edge—unless absolutely necessary.

20 Random Orbital — Video Guide

While this article centers on delta detail sanders, many handling and pressure cues carry over from quality random-orbital use. A helpful overview is “20 Random Orbital Sander Tips for Beginners,” which distills foundational habits for controlled, scratch-free sanding. It covers pad flatness, moving before start-up, consistent overlap, dust collection alignment, and the pitfalls of too much pressure—lessons that directly inform how you manage a detail sander at the edge.

Video source: 20 Random Orbital Sander TIPS for Beginners

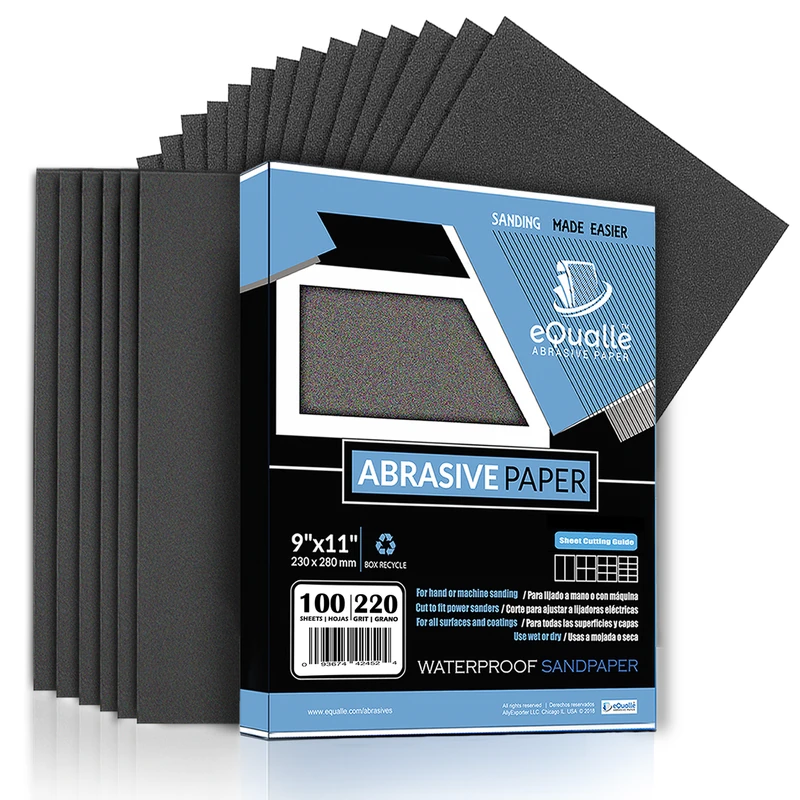

100 Grit Sandpaper Sheets (10-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Balanced coarse grit combining power and control—perfect for blending rough sanding marks before progressing to finer grades like 150 or 180. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: What grit should I stop at before touching edges with a detail sander?

A: Do not touch live edges with the detail sander below P150 unless you’re correcting mill marks on the open face and staying 2–3 mm short of the arris. Transition to a hard sanding block for P150–P220 at the edge, then optionally return to the sander at P220 only if the pad remains fully supported.

Q: Do interface pads help or hurt edge preservation?

A: Thick foam interfaces help on curved profiles but hurt crisp edges by increasing compliance and tip-rock. For edge-critical work, skip foam interfaces or use the thinnest, densest one you can, and prefer film-backed sheets on the stock hard pad.

Q: Are film-backed abrasives really better for edge control?

A: Yes. Film backings stay dimensionally stable and resist fraying at the perimeter, which keeps the contact patch consistent and reduces unintended rounding. They also shed dust more effectively when paired with good extraction.

Q: How often should I replace detail sander sheets near edges?

A: More frequently than on open faces. As soon as you feel the sheet warming or see dust smearing instead of clean particulate, swap it. Dull sheets plow and generate heat, both of which accelerate rounding at edges.

Q: What’s the fastest way to guarantee a crisp edge when time is tight?

A: Clamp a sacrificial fence flush with the edge, sand the face against that fence with a hard pad and film-backed sheet, and finish the last two grits at the edge by hand with a rigid block. This workflow physically prevents tip-in and takes guesswork out of the process.