Microscope Scratch Inspection for Abrasive Testing

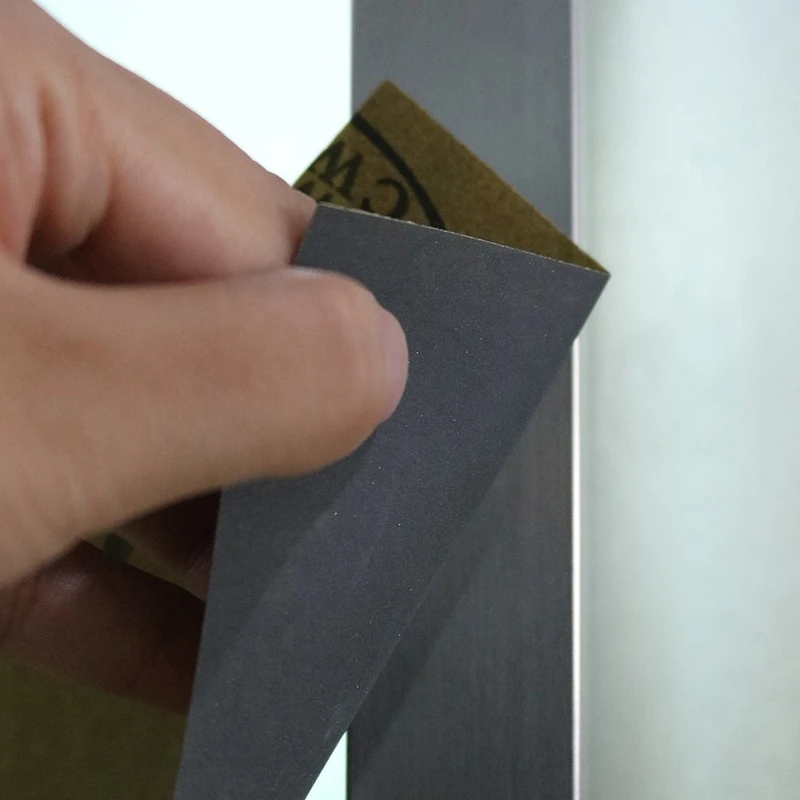

You know the feeling: the shop is quiet, the extractor hums, and that last pass felt right. You lift the part—maybe it’s a glass coupon, a knife bevel, a sanded guitar neck, or a brushed aluminum panel—and for a second it looks flawless. Then you slide it under the microscope, roll the focus, and the story changes. The surface that looked satin-smooth at arm’s length shows a lattice of scratches, smeared streaks from a loaded belt, and the ghost of an earlier grit you didn’t fully erase. That’s where abrasive testing and disciplined microscope work pay for themselves.

I’m Lucas Moreno, and I live for these moments when craft meets proof. In the shop, “good enough” gets exposed brutally by optics. Microscopy doesn’t lie: you’ll see whether you’re cutting or just plowing material, whether your coolant is helping or hurting, and whether your grit is consistent or full of stray boulders. Over time, quick microscope checks turn into second nature. You’ll start predicting the scratch pattern from the feel in your hands and the sound of the stroke—and then you’ll confirm it under glass.

This guide demystifies the microscope inspection of scratch patterns so you can act on what you see. We’ll connect the dots between your abrasive choice, technique, and the micro-evidence on the surface. Whether you’re polishing glass for optical clarity, flattening woodworking panels for a flawless finish, or chasing a crisp knife apex, the approach is the same: build a repeatable workflow, test your abrasive, read the scratch tracks, adjust pressure/chemistry/sequence, and document the results. The more consistent you make your process, the faster you become at fixing problems before they show up in the final piece.

Quick Summary: Use a microscope to read and measure scratch patterns, tie those observations to structured abrasive testing, and tune grit, pressure, and lubrication for dependable, high-quality finishes.

Why scratch patterns matter

Scratches aren’t just cosmetic; they’re an audit trail. Under magnification, a “finish” becomes a map of what your abrasive did: cutting, plowing, micro-chipping, or smearing. That map affects real outcomes—adhesion of coatings, optical clarity, friction and wear behavior, and even fatigue life on stressed parts.

- For glass and ceramics, a scratch’s cross-section tells you whether your abrasive is causing brittle micro-fractures or ductile flow. Chatter marks and lateral cracks signal too much force or too coarse a grit for the material’s toughness. On a polished glass coupon, a clean, uniform, shallow scratch field suggests controlled cutting; spiky, branched damage means rework.

- For metals, especially soft alloys, smeared “ribbons” alongside a scratch line point to built-up edge or a loaded belt. You’ll see side flow ridges and welded debris if the lubricant is wrong or pressure is too high. In hardened steels, a dense, straight scratch array can be good—unless mixed with stray deep cuts from rogue particles.

- For wood, microscopes reveal torn fibers hidden by dust. What looks like a uniform 320-grit finish on maple can show compressed earlywood with residual 150-grit valleys. Those valleys telegraph through stain and clearcoat later.

- For knife edges, the scratch angle relative to the edge tells you if your stroke is consistent. You can track burr formation, micro-chipping, and the transition from coarse to fine grits by the scratch width and density at the apex.

In short, scratch patterns are performance indicators. They tell you whether your process is under control, whether your abrasive is behaving, and whether you’ve truly reset the surface with each grit. With a microscope, you get feedback in minutes—before you commit hours to polishing or a costly finishing step.

Abrasive testing and microscope workflow

If you want consistent finishes, treat this like a mini lab. A bit of structure goes a long way. Here’s a repeatable workflow I use across materials.

- Prepare control coupons

- Choose a material sample that matches your job (same alloy, hardness, or glass composition).

- Flatten or lap the coupon so it starts uniform.

- Clean with isopropyl alcohol and lint-free wipes; compressed air for dust. Handle with nitrile gloves.

- Define your test matrix

- Variables: grit size, abrasive type (AlOx, SiC, diamond, CBN), speed (SFM), pressure (N), lubricant (water, oil, surfactant), and stroke count/time.

- Change one variable at a time. Record everything—even ambient temperature and humidity if you’re chasing very tight finishes.

- Baseline microscope setup

- Use a 10–50× view for general scratch fields and 100–200× for edges and micro-fractures.

- Lighting matters: start with oblique (low-angle) light to highlight topography; try darkfield to pop scratch edges; use cross-polarization on glass or shiny metals to reduce glare.

- Calibrate your measurement: a simple stage micrometer lets you convert pixels to microns and add scale bars later.

- Execute and inspect

- Run each condition for a fixed number of strokes or time, cleaning the surface before imaging.

- Take images at the same magnifications and orientations each time.

- Measure scratch width, spacing, and outliers (rogue deep cuts). Note defect types: plowing, smearing, micro-chipping.

- Compare, decide, lock it in

- Pick the recipe that gives the narrowest scratch width distribution and the least defect types for your target finish and throughput.

- Save the images and notes so you can repeat it next month, or hand it to a teammate.

Five practical tips that save hours:

- Break-in new abrasives: run a few strokes on scrap to knock down oversized grains so they don’t carve random deep trenches in your part.

- Keep a “witness mark” habit: always orient the last grit at a distinct angle (e.g., 45°), then switch to 90° for the next grit. Under the microscope, leftover scratches from the previous grit stand out immediately.

- Control pressure with numbers: clamp a luggage scale or inline force gauge to your fixture to keep hand pressure consistent across tests.

- Clean between grits with purpose: rinse, wipe, and air blast—one stray 80-grit particle in your 400-grit stage will show up as a railroad track under the scope.

- Track abrasive age: label belts and stones with run time; aging, friability, and loading change scratch morphology even when grit numbers match.

Interpreting what you see

Once you have decent images, it’s time to read them. Think like a detective: morphology, frequency, and anomalies.

- Cutting vs. plowing: Cutting produces clean, V-shaped scratch profiles with minimal side flow. Plowing shows raised ridges and smeared material alongside the groove—often due to dull grains or excess pressure.

- Fracture signatures: In brittle materials (glass, ceramics), look for lateral cracks branching off a primary groove. These mean your grit is too coarse, your force too high, or the lubricant is not mitigating heat and stress.

- Loaded abrasive: If you see broad, shiny swaths instead of discrete lines, your abrasive is skating on packed debris. Clear it with a dressing stick (for stones) or cleaning stick (for belts), and confirm the scratch field tightens up.

- Rogue boulders: Occasional deep trenches indicate oversized particles or contaminants. Sieve new media when possible, or switch lots.

- Grit transition completeness: After stepping to a finer grit, the earlier scratch angle should fully disappear. If you still count earlier-angle scratches at 5–10% prevalence, you haven’t reset the surface; extend time, add cross-hatching, or reduce pressure to let finer grains cut.

Measure scratch width to sanity-check grit claims. As a rule of thumb, the average scratch width is a fraction of the abrasive particle diameter and varies with hardness and lubrication. Track minimum, average, and maximum scratch widths. If the maximums are consistently double the average, you either have poor grading or excessive force.

On glass specifically, optical microscopy reveals whether you’re in a microabrasive regime (predominantly polishing with micro-cuts) or causing larger-scale damage. According to a article. The takeaway for the shop: tiny changes in force and particle size distribution translate into big changes in the scratch pattern and downstream performance.

Tie behavior to materials:

- Aluminum: easy to smear; water with a dash of surfactant helps carry swarf; keep pressure low to avoid galling scratches.

- Hardened steel: stays crisp; watch for micro-chipping at the apex when too aggressive; diamond and CBN leave narrower, more uniform tracks.

- Glass: keep force light and distribution tight; a wayward large particle is immediately visible as a prominent gouge and lateral cracking.

Dialing in grit, pressure, and lube

Optimization is not guesswork. Use the microscope to establish a feedback loop and tune three levers: grit progression, applied force, and lubrication/coolant.

- Grit progression: Jumping from 120 to 600 sounds efficient, but microscopes expose the lie. Use ratio steps of roughly 1.5–2× in particle size (e.g., 120 → 180 → 240 → 320 → 400 → 600). At each step, orient your strokes differently to verify the previous scratches vanish entirely.

- Pressure: Too light and you burnish; too heavy and you plow or fracture. Start by targeting the narrowest, most uniform scratch field that appears with minimal side ridges. In hand work, use timed sets with a scale feedback: if your “normal” push is 25–30 N and that yields ridges on stainless, back off to 15–20 N and recheck.

- Lubrication: Water reduces heat but can promote loading on some metals; light oil improves cutting for fine stones on steel; a tiny amount of surfactant in water breaks surface tension and clears debris on glass. Watch how the scratch edges change—sharper edges indicate effective chip evacuation and cooler cutting.

A short, shop-ready routine:

- Start coarse enough to reset the surface quickly, but not so coarse that you create deep valleys that take forever to chase out.

- Dress or condition your abrasive whenever the scratch field starts to widen or smear.

- Don’t be afraid to add an intermediate grit if the microscope says you’re spending too long erasing a pattern. Time saved downstream beats saving one abrasive change.

Three targeted tips for faster wins:

- Map your “pressure window” for each material: do a three-step pass—light, medium, heavy—on one coupon, image all three, and circle the range that produces clean, narrow scratches without side ridges.

- Tune lubricant in micro: run 30 seconds dry, 30 seconds water, 30 seconds water + a drop of dish soap on identical coupons; compare scratch edge sharpness and debris trails to pick your winner.

- Set a strict acceptance criterion: “No prior-angle scratches at 50×, no smeared streaks at 100×.” Stop only when the microscope says so.

Documenting and sharing results

Your memory is good; your records are better. Consistent documentation turns one-off wins into a repeatable system—especially when you’re training a team or revisiting a finish months later.

- Standardize images: Same magnifications (e.g., 20× overview, 50× detail, 100× critical zone), same lighting angle, and a scale bar on every shot. Add a North arrow; orientation helps you spot previous-grit leftovers fast.

- Capture context: Store photos alongside parameters—grit, abrasive type/brand/lot, speed, pressure, lubricant, time/strokes, material specs, and teardown notes. A simple spreadsheet or shared note system works.

- Name with intent: Try “2025-01-18_304SS_320SiC_20N_Water_50x.jpg.” You won’t waste time guessing what you’re looking at six months later.

- Build before/after pairs: For every grit change, take a quick “last pass of old grit” and a “first pass of new grit” image. Reviewing these pairs accelerates training and tightens your intuition.

- Create a reference library: Keep a set of “golden” images for your standard finishes. New hires can calibrate their eyes by matching to these references under the microscope.

If your work touches QA or contracts, wrap it together as a one-page report: objective (target Ra or appearance), materials, abrasive lot, method, images with annotations, and a go/no-go statement. It’s not busywork; it’s insurance—and it shortens the path to consistent quality when variables creep in, like a new abrasive shipment or a seasonal humidity shift.

Abrasive Particle Size — Video Guide

A short, practical clip worth your time walks through testing abrasive particle size using a dedicated test kit. The host breaks down why consistent grading matters and how to verify the size distribution with a straightforward, shop-friendly method. You’ll see the process for confirming your media matches the label—before it touches your part.

Video source: Abrasive Particle Size Testing

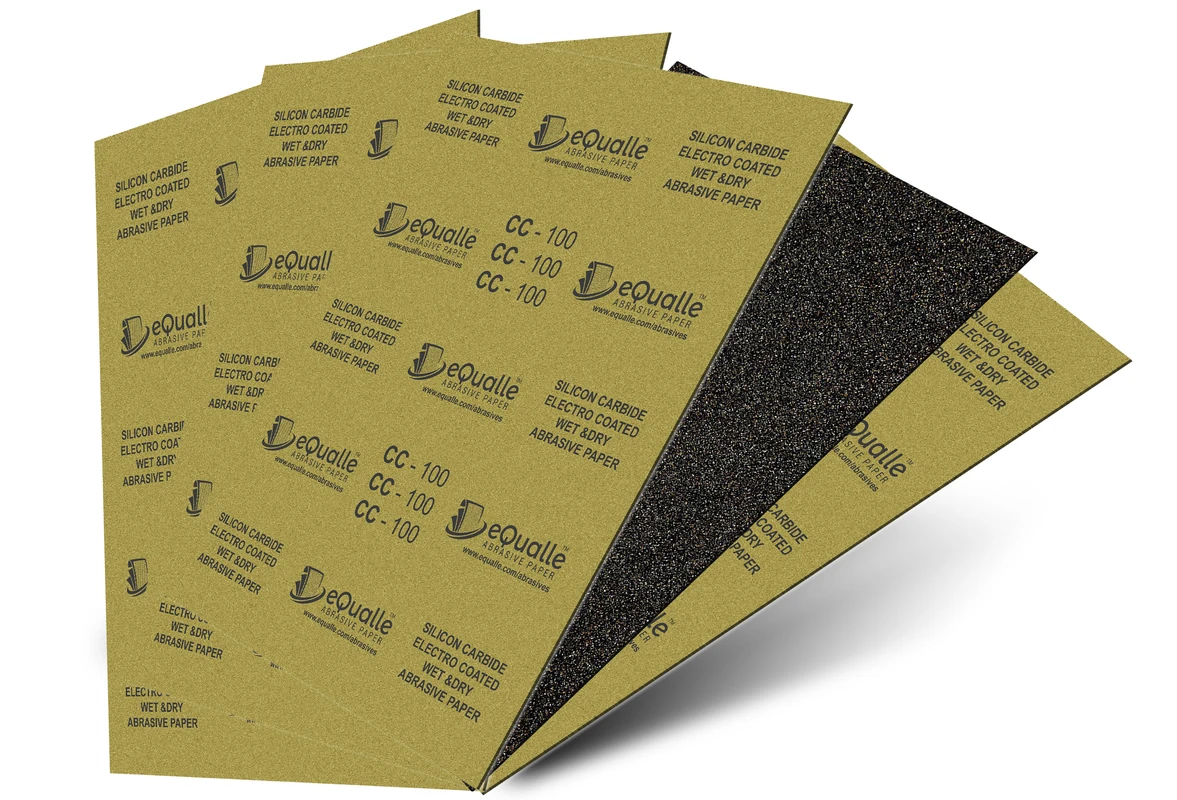

240 Grit Sandpaper Sheets (50-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Light refinement grit that blends sanding marks and smooths primer layers. Perfect for wood, resin, or plastic before lacquer application. Produces consistent scratch patterns and controlled results when used wet or dry. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: What magnification should I use to inspect scratches?

A: Start at 10–20× for overall pattern and uniformity, then use 50–100× to confirm removal of the previous grit and spot defects like plowing, loading, or micro-chipping. For knife edges or glass microfractures, 150–200× helps, but only after you’ve assessed the broader field.

Q: Can a cheap USB microscope do the job?

A: Yes, for most shop checks. Look for stable focus, adjustable illumination, and at least 50–100× optical (not just digital) magnification. Add a stage micrometer to calibrate measurements, and use oblique lighting to make scratches pop.

Q: How do I avoid false readings from contamination?

A: Clean between grits with a rinse, lint-free wipe, and air blast; switch to fresh gloves; and keep your bench and microscope stage dust-free. One stray coarse particle can create tracks that look like process failure.

Q: How many samples do I need for reliable abrasive comparisons?

A: For shop decisions, test at least three coupons per condition and average the scratch width and defect counts. If variability is high, stabilize your pressure and lubrication, then retest.

Q: Can scratch patterns predict surface roughness (Ra)?

A: They correlate, but not one-to-one. Narrow, uniform scratch fields generally yield lower Ra. Use microscopy to verify complete grit transitions and defect absence, then spot-check Ra with a profilometer to build a correlation for your specific material and process.