Rust Repair 101: Grind, Feather, and Patch Like Pro

The moment you notice it is rarely dramatic. Maybe you’re pouring your first cup of coffee, the driveway still cool in the morning shade, when a small bubble on the wheel arch catches your eye. It wasn’t there last summer. You press lightly; the paint flexes and flattens like a blister. It’s a tiny flaw, easy to ignore while the engine warms and the day rushes in. But you know how rust works. It doesn’t wait. It keeps chewing, one quiet day after another, under glossy paint where you can’t see it.

That’s when rust repair becomes more than a task; it’s stewardship. You don’t need a restoration shop or a welder to make a meaningful difference. With the right approach—grind out the corrosion completely, feather your paint edges to a soft, invisible transition, and choose the right patch method—you can keep the body strong, the lines clean, and the fix reliable. The work is tactile and focused, a series of careful steps that favor patience over force. The first time you reveal clean, bright steel beneath the flaky brown, it’s oddly satisfying. You’re not just removing damage; you’re reclaiming structure and shape.

On good days, the process becomes a ritual. Tape a neat boundary. Spin up the grinder. Work in arcs. Stop and check heat with the back of your hand. Switch to finer abrasives and watch the sharp ledge of paint soften into a gentle slope. Prime, fill, sand, repeat—each pass quieter than the last. This is how you turn a small blemish into a finish you can be proud of, one that holds through winter, salt, and time. If you’re new to rust repair, the steps below are designed to help you move steadily from diagnosis to a clean patch that blends in, lasts, and looks right in the sunlight.

Quick Summary: Remove every trace of active rust, feather surrounding paint into a smooth taper, then build a properly sealed patch with the right materials for a long-lasting, nearly invisible repair.

Rust’s root causes and hidden spread

Rust doesn’t just happen where you can see it. Steel rusts when iron, oxygen, and moisture meet, and road salt acts like a catalyst by speeding up the electrochemical process. Capillary action wicks salty water under paint and seam sealer, and once corrosion starts, the expanding oxide lifts the finish, creating bubbles that draw in more moisture. That’s why a nickel-sized blister can hide a quarter-sized hole or a palm-sized patch of weakened metal.

Understanding how rust spreads helps you set realistic boundaries for repair. If you grind only the visible spot, you often leave an “orange halo” of pitted, compromised steel that will creep back through your finish. The fix is to chase the rust outward until your grinder exposes uniform, shiny metal. Expect to remove paint and primer several inches beyond the bubble—two to three inches is a common taper for small repairs, and more for panels that have seen multiple seasons of salt.

Also consider the geometry of the panel. Lower door skins, wheel arches, rocker panels, and pinch welds trap mud and water. Drains clog, seams crack, and inner and outer skins rust from the backside first. When you open a spot, look for layered corrosion: the top surface may look clean while the inner lip is brittle. A small inspection mirror and flashlight can reveal under-lip damage and guide whether you patch from the back, reinforce with fiberglass cloth, or cut and weld.

In short: rust hides. Your plan should assume that the damage extends beyond what you can see. The grinding phase is not just about removal; it’s also your diagnostic tool. Let the metal tell you where to stop.

Tools and safety for rust repair

Good results come from the right tools used safely. You don’t need a full body shop, but thoughtful choices make each step cleaner and more controlled.

Core tools:

- Angle grinder (4.5") with variable speed if possible

- Flap discs: 40–60 grit for removal, 80 grit for refining

- Surface conditioning discs (non-woven) for smoothing and scuffing

- Dual-action (DA) sander with 120, 180, 220, and 320–400 grit discs

- Wire cup or wire wheel (stainless or brass) for seams and crevices

- Carbide burr or small cutoff wheel for precisely opening holes

- Body hammer and dolly for gentle reshaping of thin panels

Measuring and masking:

- Automotive masking tape (3/4" and 1.5")

- Flexible spreader and contour gauge or a simple index card to pattern curves

- Straightedge and a scribe or permanent marker to set boundaries

Chemicals and coatings:

- Wax and grease remover for clean surfaces at every stage

- Epoxy primer (2K) for bare metal sealing

- Fiberglass-reinforced filler (short-strand) for structural shaping

- Lightweight finishing glaze for final surfacing

- Rust converter or encapsulator for inaccessible internal cavities only

Safety essentials:

- P100 respirator or half-mask with particulate and organic vapor cartridges

- Safety glasses and hearing protection

- Nitrile gloves and long sleeves

- Good ventilation and a shop vacuum with HEPA attachment to control dust

A few selection tips: Flap discs cut quickly but can dish thin sheet metal if you bear down; use light pressure and keep a shallow angle (10–15 degrees). A DA sander with 120–180 grit helps create a consistent feather edge without gouges. Reserve rust converters for areas you truly can’t reach with abrasives—converters are helpful, but they’re not a substitute for removing active corrosion. Lastly, prioritize epoxy primer over rattle-can primers for bare metal; epoxy seals better and resists moisture migration, giving your patch a strong foundation.

Grind smart: expose solid, shiny steel

Grinding is where you win or lose the longevity of your repair. The goal is simple: remove every trace of active rust and stop only when you’re into solid, uniform steel.

- Map the boundary

- Use masking tape to outline a perimeter two to three inches beyond the visible bubble or scab. This gives you space to feather paint later and ensures you’re not grinding in a tight box.

- Strip paint and rust

- Start with a 60-grit flap disc at low-to-medium speed. Hold the grinder at a shallow angle and keep it moving in overlapping arcs. Work outward in layers: paint first, then primer, then the oxidized metal. If heat builds, pause. Excess heat warps thin body panels; check with the back of your hand—warm is fine, hot is not.

- Inspect and chase the orange

- Wipe with wax and grease remover, then look closely. Orange tint, pitting, and black shadows in the grind marks suggest remaining corrosion. Probe with a pick; if the metal flakes or crumbles, you’re not done. Continue grinding until the area shows consistent, bright silver with no dark pits.

- Define the hole cleanly

- If the rust has perforated the panel, open the hole to solid metal with a carbide burr or small cutoff wheel. Jagged edges trap moisture and make patches fail. A smooth, slightly beveled edge bonds better to fiberglass or filler and welds cleaner if you’re going that route.

- Smooth the cut and prep for feathering

- Switch to 80 grit to refine grinder marks. You want shallow scratches that a DA sander can blend. Vacuum dust and wipe clean.

Practical cues that you’re there: the grinder throws bright silver sparks instead of red/orange; your pick doesn’t find soft spots; the surface reflects light evenly. If the area keeps expanding, step back and reassess whether a welded patch is necessary. Never bury questionable metal—rust is relentless and will telegraph through even the most beautiful paint.

Feather the edges for seamless paint

Feathering is how you make your repair vanish. The aim is to taper the layers—bare metal, primer, old paint, and any remaining clear—into a gentle slope rather than a hard ledge, so the new coatings lie flat and your eye doesn’t catch a line in the sun.

- Create a gradual taper

- With a DA sander and 120 grit, overlap your grinder boundary by an inch, blending the sharp edge of remaining paint into bare metal. Work in crescents and keep your pad flat; tilting digs valleys. You’re sculpting a smooth transition, not chasing every last speck of old primer.

- Step through grits

- Move to 180 grit to refine the taper, then 220. By 320, your fingertip should feel almost no step between old and new surfaces. Use a dry guide coat or a quick mist of contrasting paint and sand lightly; low spots will show immediately.

- Clean and seal

- Vacuum and wipe with wax and grease remover. Apply two medium coats of 2K epoxy primer over all exposed metal and onto the feathered paint—think of it as your moisture lock. Follow the manufacturer’s flash times; rushing primer traps solvents and can cause lifting later.

Feathering also sets you up for blending color. Modern finishes are layered, and an abrupt paint edge is what makes many DIY patches shout “repair.” A well-feathered boundary gives you room to blend basecoat and then fade clearcoat outward, so the transition disappears when buffed.

Feathering may sound like a cosmetic step, but it directly affects durability. Paint that bridges a hard ledge chips easily; a tapered edge holds up to washing, road grit, and seasonal expansion. If you’re new to this, practice on a scrap panel to learn how the DA “feels” when the edge is right. Precision here saves time later in sanding and polishing. According to a article, feathering the sprayed edges helps hide the transition between old and new paint, which is exactly what you want for a near-invisible finish.

Patch options: filler, fiberglass, or metal

Once the rust is gone and your edges are feathered, choose how to rebuild the surface. Your decision depends on hole size, access to the backside, and whether the area is cosmetic or structural.

Small pits and no perforation

- After epoxy primer cures, use a thin layer of fiberglass-reinforced filler (short-strand) to bridge minor pitting and restore the panel’s contour. Block-sand with 80, then 120, and finish with a lightweight glaze. The fiberglass strands add stiffness and resist pinholes.

Small holes (up to a nickel) with backside access

- Epoxy, then back the hole with fiberglass cloth wetted with resin, extending at least one inch beyond the opening. Once cured, skim the front with short-strand filler to tie everything together, then switch to lightweight filler for final shaping. This method resists moisture better than using body filler alone.

Larger holes or stressed areas

- Cut out to clean metal and weld in a patch of matching gauge steel. If you don’t weld, consider a metal patch bonded with panel adhesive designed for structural repairs. It requires clean, bare metal on both sides and precise clamping but offers strong, corrosion-resistant results.

Edges, seams, and complex curves

- Build structure with layers: fiberglass cloth first for strength and shape, then reinforced filler, and finally a finishing glaze. Avoid thick applications of any one product; multiple thin layers cure better and sand more predictably.

Sealing is non-negotiable. After shaping, apply epoxy primer again, then high-build primer. Block-sand with 220–320 to flatten and 400–600 before basecoat and clear. Inside cavities, fog cavity wax through access holes so the back of your repair isn’t left bare. Water finds unprotected edges; wax keeps it moving.

Pro tips for durability

- Extend your epoxy primer at least one inch onto scuffed old paint so the seam is well sealed.

- Keep filler thickness under 1/8 inch; if you need more, re-evaluate the metalwork or add fiberglass cloth for strength.

- Warm the panel and materials to room temperature; cold resin and fillers cure weak and sand poorly.

- After paint, apply cavity wax behind the repair and along seams; reapply annually in rust-prone climates.

- On rocker panels and wheel arches, add a thin stone-chip or flexible underbody coating over paint to resist chips.

How to Repair — Video Guide

If you don’t own a welder, you can still fix small perforations cleanly. A helpful walkthrough demonstrates how to use fiberglass cloth and resin to bridge a rust hole, then build the surface with reinforced filler and finish with standard body filler and primer. It covers surface prep, layering technique, curing times, and sanding steps so the patch bonds well and looks smooth.

Video source: How to Repair a Rust Hole with Fiberglass - No Welding!

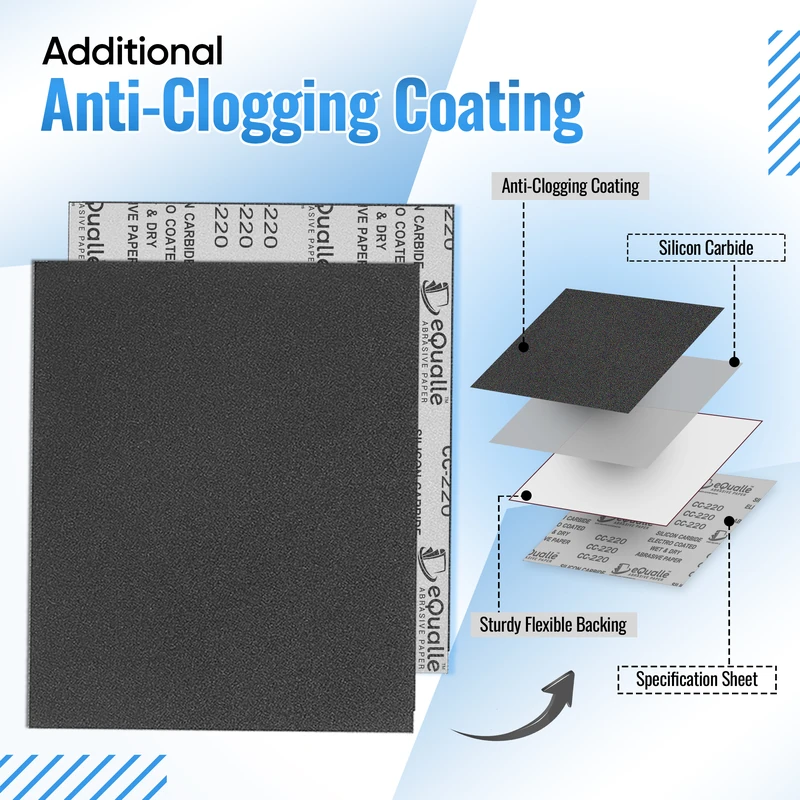

1000 Grit Sandpaper Sheets (25-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Gentle polishing grit that removes swirl marks and fine scratches on automotive or resin finishes. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: How far beyond the rust spot should I grind?

A: Grind until you reach bright, uniform steel with no dark pits, plus at least 2–3 inches into surrounding paint to give space for feathering. The boundary is set by clean metal, not by what you wish to keep.

Q: Can a wire wheel replace grinding with a flap disc?

A: No. Wire wheels can clean light surface rust but won’t remove deep pitting effectively. Use a flap disc to cut back to solid metal, then a wire wheel for seams and texture. Think of the wire wheel as a cleaner, not a primary remover.

Q: What’s the correct grit sequence for feathering edges?

A: After initial grinding, use a DA with 120 grit to soften the edge, then 180 and 220 to refine. Finish feathering with 320–400 before epoxy and primer-surfacer. Use a guide coat to verify the transition is smooth.

Q: Do I need epoxy primer, or can I use rattle-can primer?

A: Use 2K epoxy primer on all bare metal. It seals against moisture far better than most aerosol primers. You can apply high-build primer over epoxy for sanding, but always ensure epoxy is your first coat on steel.

Q: How long will a no-weld fiberglass/filler repair last?

A: If you remove all active rust, seal both sides (including cavity wax inside panels), and keep chips touched up, a cosmetic repair can last several years—even in salty climates. Skipping rust removal or sealing shortens its life dramatically.