Resin Polishing: Clean Pads, Zero Micro Marring

I’ve watched the same scene a hundred times: you finish a long day of shaping, sanding, and dialing in the gloss. The shop is quiet, the floor swept, your coffee cold. You swing the work light across the panel—maybe it’s a black hood, a river table, or a batch of resin bangles—and your stomach sinks. There it is: a faint gray haze of tiny trails that weren’t visible under the shop lights. That’s micro marring, and nine times out of ten it’s not your machine, polish, or even your technique—it’s what’s happening at the pad face. This is where cleaning while you work becomes the difference between “almost” and “absolutely flawless,” whether you’re finishing paint or doing resin polishing on jewelry and tabletops.

If you’ve ever said, “I don’t get it, I did everything right,” you’re not alone. Micro marring sneaks in as pads load up with spent abrasive, resin dust, and oils. The pad goes from cutting cleanly to skating and dragging. Heat builds, fibers mat down, and the working face smears more than it refines. The solution isn’t magic—it’s a workflow that keeps the pad cutting clean: frequent cleaning, smart pad rotation, and the right match of pad density to surface hardness.

I’m Lucas in the shop, and I want you to get consistent, repeatable clarity from your finish. This piece breaks down what causes micro marring and gives you a hands-on plan to stop it. You’ll get a maintenance rhythm that keeps finishes sharp on vehicle paint, acrylic shields, and epoxy resins alike. You’ll also see how a few small changes—like cleaning every section or two—return the gloss you thought you’d bought with expensive compounds. The goal is simple: turn the light across your work and smile instead of sigh.

Quick Summary: Micro marring comes from dirty, overloaded pads—clean and rotate pads frequently, match pad and polish to the surface, and maintain pad health to lock in a swirl-free finish.

What Makes Pads Cause Micro Marring

Micro marring is the fine, uniform haze that robs depth from otherwise polished surfaces. It’s not deep enough to feel, but under a strong LED you’ll see a matte bloom or faint trails. The main culprit is pad contamination and transition—when a pad moves from “fresh, open-faced foam or microfiber” to “loaded, hot, and smeary.”

Here’s what’s happening at the pad face:

- Spent abrasives and cut-off material accumulate. This slurry acts like ultra-fine sand but with uneven particle size that drags instead of refines.

- Heat softens the surface—particularly true for fresh clear coat and epoxy—and the pad smears softened material across adjacent scratches, creating a haze.

- Pad fibers or foam pores mat down. Instead of holding abrasives evenly, the pad becomes a slick puck that skates and scuffs.

- Oils and fillers in compounds reduce bite. With no fresh faces exposed, the pad pushes product around, leaving uniform micro haze.

On compliant or soft materials like epoxy and acrylic, micro marring shows up fast with aggressive pads or too much pressure. On cured automotive finishes, the same effect creeps in as compound dries and the pad goes dry-drag. The fix is proactive: clean the pad often enough that it never enters the smeary zone.

Three core checkpoints to prevent the problem:

- Temperature: If the pad feels hot to the touch, back off, cool, and clean. Heat accelerates smearing and marring.

- Face condition: If the pad face looks shiny or glazed, it’s time to brush or blow out—shiny foam is marring foam.

- Product film: If you’re seeing oily streaking or dry dusting, adjust your priming and dosing, then clean. Either condition promotes haze.

This is less about chasing the perfect product and more about controlling the working interface—your pad—throughout the session.

Cleaning As You Go: Methods That Work

In a real workshop, you don’t have time to tear everything down after every pass. You need quick, repeatable pad-cleaning methods that keep the face open without soaking your workflow.

Field‑tested ways to clean on the fly:

- Compressed air: My first choice for microfiber and foam. After each 18”×18” section, run low to moderate air across the face while spinning the DA at slow speed (1–2). This lifts spent abrasive and fluffs fibers.

- Pad brush or nylon detailing brush: With the machine off, support the pad and brush from the center outward to re-open pores. Ideal mid-pass if you don’t have air.

- Microfiber towel “grab”: Hold a clean microfiber edge lightly against a slow-spinning pad. It wicks off excess product and residue quickly.

- Dedicated pad washer: Great for shop setups with lots of panels. Just remember to spin‑dry thoroughly; a waterlogged pad will sling and can mar.

Practical timing that prevents haze:

- Compound step: Clean every section or at most every other section. Compounds shed more residue.

- Polish/jewelry finish step: Clean every section; finer abrasives load pads quickly, especially on soft resin.

- After any hot spot or heavy pressure: Stop and clean immediately.

Actionable, shop-floor tips:

- Use two of each pad type and alternate. While one cools and dries post-clean, the other works—heat control is haze control.

- Mark pad edges with a Sharpie to track rotation and wear. Retire pads as they glaze; a tired pad is an instant haze-maker.

- Prime once, then use small product drops. Overloading is the gateway to build-up and micro marring.

- Keep a “finishing only” set of pads bagged and clean. Cross-contamination from compound to finishing pad creates uniform haze.

- If a pad feels bouncy or smeary, swap it—don’t fight it. The two minutes you save now will cost you two hours later.

Pad Choices And Surface Safety

Matching pad and polish to the material matters as much as cleaning. Soft surfaces—fresh clear coat, acrylic, cast resin—show micro marring earlier, so choose gentler pad interfaces and run cleaner.

For cutting on paint or hard, fully cured epoxy:

- Microfiber cutting pads with a DAT or SMAT compound handle defect removal fast. Keep air on hand; MF loads quickly.

- Medium foam cutting pads are safer on edges and curves. They hold a clean face longer but still need frequent brushing.

For refining/finishing:

- Closed-cell, soft foam finishing pads pair well with finishing polishes on cured paint and acrylic shields, minimizing residual haze.

- Ultra-soft foam or one-step polishing pads are ideal when you plan to jewel the finish. Keep pressure low and machine speed moderate.

Speed and pressure rules of thumb:

- DA polishers: Speeds 3–4 to cut, 2–3 to finish. Too fast creates heat and smearing; too slow can chatter and scuff.

- Pressure: Use firm, even pressure for cutting, but lighten up on the last 2–3 passes until the pad just kisses the surface. Micro marring often appears when you fail to reduce pressure during the refining phase.

Inspection matters:

- Use a high-CRI inspection light, not just overhead shop LEDs. Move the light at a low angle to reveal haze directionally.

- Wipe panels with a dedicated panel wipe or isopropyl mix (10–25% IPA in distilled water) to strip oils that can mask micro marring.

According to a article, even seasoned DA users see swirls when pad cleanliness slips. That’s your reminder: the clean pad is your “third hand” stabilizing the finish.

Pad Care For Resin Polishing And Paint

Resin polishing has unique challenges. Epoxy and cast resin warm quickly, clog pads with ultra-fine dust, and mark easily if you rush. The cure is deliberate sanding sequences and hyper-clean pad discipline.

Foundation: flatten and refine first

- Sand wet through a full grit ladder: 400/600/800/1000/1500/2000/3000. Don’t skip grits. Each step removes the previous scratches so your polishing pads don’t overwork and smear.

- Keep the surface cool. If water runs warm, swap it; warm resin smears under pressure and primes a pad for haze.

- Wipe between grits with a fresh microfiber to remove slurry. Cross-grit contamination is marring fuel.

Polishing workflow that prevents haze:

- Prime a medium foam polishing pad lightly with your chosen plastic/resin polish. Work a small area and keep speeds moderate (DA 2–3).

- Clean the pad after every small section—resin dust is ultra-fine and loads fast. Air blowouts or a microfiber grab work great.

- Transition to a softer finishing foam and a jeweling polish. Reduce pressure to near-zero for final passes.

- If you see uniform haze, don’t chase it with more pressure. Stop, wipe with panel cleaner, clean or swap the pad, and take one clean, slow pass.

Pro tips for resin and paint alike:

- Dedicate pads by material: “Resin Only” and “Paint Only” bins. Resin dust left in a pad will create ghosting on paint.

- Work smaller areas on resin than paint. Heat density matters on small pieces like jewelry.

- If you’re finishing a deep-black epoxy river table, use a fresh finishing pad for the final two passes—don’t reuse the one from the previous section.

The overlap between automotive finishing and resin polishing is strong: both reward cleanliness and punish shortcuts. Treat the pad like a consumable, not a forever tool, and your clarity will jump.

Maintenance Between Jobs And Storage

Clean-as-you-go is half the battle; the other half is how you deep-clean and store pads so they start the next job ready to perform. A pristine-looking pad can still cause micro marring if loaded with dried polish or embedded dust.

Post-job deep cleaning:

- Pre-rinse pads in lukewarm water to release loose residue. Hot water can set some binders and stiffen foam.

- Use a dedicated pad cleaner or a mild APC diluted per label. Massage foam with your fingers; for microfiber, brush before and after soaking.

- Rinse until water runs clear. Any lingering suds or discoloration means residue remains that can transfer and haze.

- Spin-dry on the machine in a bucket to contain sling, then blot with a clean microfiber.

Drying and storage:

- Air-dry face-up on a clean rack. Avoid high heat or direct sun that can warp backing or harden foam.

- Label and bag by stage: “Cut,” “Polish,” “Finish,” with separate bags for paint and resin.

- Retire pads early. If the face looks glazed, torn, or permanently matted, it’s cheaper to replace than to rework a hazed finish.

Actionable maintenance tips:

- Keep a simple bin system: “Dirty,” “Washed,” “Ready.” Move pads through in one direction only to avoid accidental reuse.

- Log pad cycles with a marker on the backing—after 6–10 heavy uses, reassess performance.

- Avoid fabric softeners and harsh degreasers; they leave residues that smear and can weaken adhesives.

- Inspect hook-and-loop backing. Lifted edges cause wobble, wobble causes heat, and heat invites marring.

Start every job with truly clean, dry pads and you’ll notice how much less product you need—and how much faster you land a crisp, swirl-free finish.

Different Polishing Options — Video Guide

There’s a helpful short video that walks through several approaches to finishing resin jewelry, comparing hand and machine methods, and showing how different compounds and pads affect clarity. You’ll see how simple changes—like pad choice and cleaning frequency—shift results from cloudy to glassy.

Video source: Different Polishing Options for Resin Jewelry

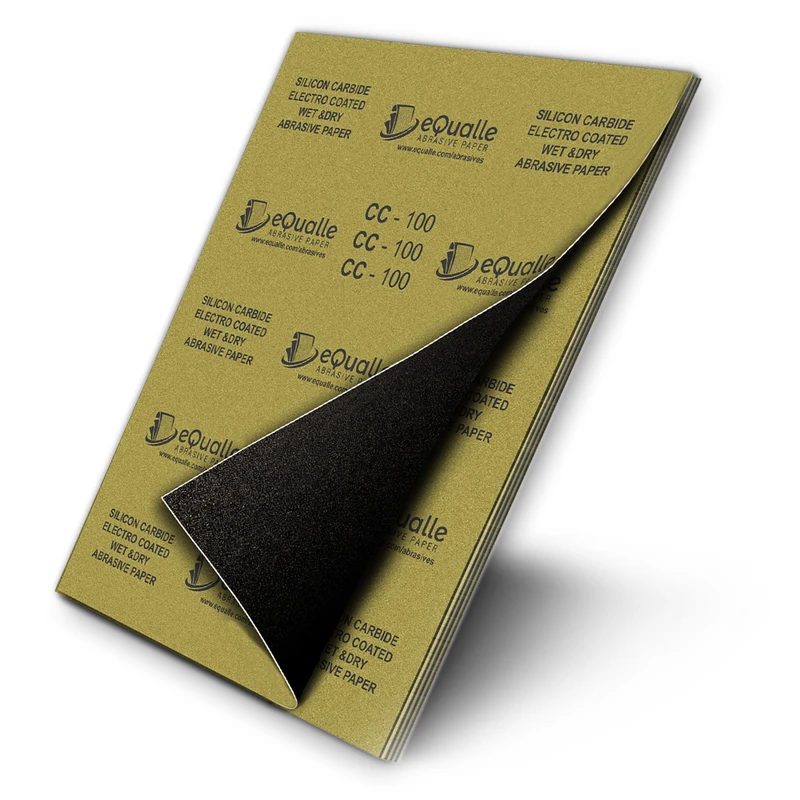

1000 Grit Sandpaper Sheets (10-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Gentle polishing grit that removes swirl marks and fine scratches on automotive or resin finishes. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: How often should I clean my pad during polishing?

A: Clean every section during finishing and at least every other section during compounding. If the pad feels hot or looks shiny, clean immediately.

Q: What’s the best way to clean pads without a compressor?

A: Use a nylon pad brush between sections and a microfiber “grab” against a slow-spinning pad. For deeper cleaning, soak in a dedicated pad cleaner and rinse thoroughly.

Q: Why does micro marring show up more on resin than paint?

A: Resin warms and smears faster, and fine resin dust loads pads quickly. Smaller sections, lower speeds, frequent pad cleaning, and cooler work temps reduce haze.

Q: Can I use the same pad for compound and finish if I clean it?

A: It’s safer to dedicate pads by step. Even well-cleaned pads can hold compound residue that induces uniform haze during finishing.

Q: Does pad speed matter for preventing micro marring?

A: Yes. Excessive speed builds heat and smears; too slow can chatter. Aim for DA speed 3–4 to cut, 2–3 to finish, and lighten pressure on final passes.