Glass Sanding Insights for Perfect Tile Edges

You notice it first with your fingertips. The bathroom is almost finished—the new vanity, the grout drying to a warm gray, the light bouncing off fresh ceramic. But as you reach to wipe away a stray haze line, a sharp corner catches your skin. It’s tiny, the sort of edge that doesn’t look like much, yet it steals the comfort from the space an inch at a time. Uniformly honed tile edges are what make a shower niche feel intentional, a kitchen backsplash look built-in rather than glued on. The margin between “nice” and “nailed it” often lives right there—at the line where glaze, clay, and air meet.

If you’ve ever watched a craftsperson finish a glass tumbler, the care is unmistakable: slow, wet passes; a measured angle; and a precise sequence of abrasives. That’s the mindset behind professional glass sanding, and it translates surprisingly well to ceramic tile. Both materials are hard, brittle, and unforgiving of shortcuts. Get the pressure or the grit wrong and you create chips that bloom into cracks, a dull halo that won’t polish out, or a bevel that wanders from piece to piece. Get it right and edges feel soft without losing their crisp geometry, grout transitions tighten up, and the whole installation reads as one continuous surface.

This guide distills the know-how from studio glass finishing and tile trade best practices to help you hone ceramic tile edges uniformly—consistently, cleanly, and safely. You’ll learn how to choose the right abrasives, set an angle you can hold, work wet, and confirm your progress with simple visual checks. By the end, those touchy corners will turn into smooth, resilient edges that invite the hand rather than warn it away.

Quick Summary: Use a wet, progressive-grit approach—borrowed from glass sanding—plus angle control, light pressure, and repeatable checks to hone ceramic tile edges uniformly.

Why uniform edges matter

Uniformly honed edges do more than save fingertips. They influence how your tile field aligns, how grout seats, and how light travels across a wall. Consider a shower niche lined with porcelain. If the perimeter tiles have inconsistent bevels—some sharp, some softened—the eye reads the opening as slightly out of square, even when your measurements are perfect. A consistent chamfer or round-over creates a visual frame that feels deliberate.

Safety is a quieter benefit. Sharp factory edges, especially on rectified porcelain, can be knife-like after cutting. In high-traffic areas or kid-friendly spaces, easing that edge reduces accidental scrapes. Even a subtle 0.5–1.5 mm micro-bevel makes daily use more comfortable without changing the clean, modern look most people want from ceramic and porcelain.

Performance matters too. Grout bonds and compacts more predictably against a uniform edge. When one tile has a steeper bevel than the next, grout depth varies, which can lead to micro-cracks or premature wear. Around corners—benches, curb tops, shelving—honed edges reduce the risk of small fractures that start at tiny chips and travel inward over time. The result is a longer-lasting installation with fewer callbacks for edge touch-ups.

Finally, finishing edges is your chance to “tune” the feel of a design. Traditional stone often carries a soft, tactile lip; contemporary ceramic tends to present a crisper line. By controlling the edge geometry, you can keep the character you want—sharp enough to read as precise, softened enough to feel refined. With a repeatable honing process, every piece contributes to that intent, and the whole room benefits.

Lessons from glass sanding for tile edges

If you’ve tried glass sanding, you already understand the core recipe for uniformity: progressive grits, water management, angle control, and pressure discipline. These four elements also make ceramic edges consistent from the first tile to the last.

Progressive grits: Start coarse enough to establish the shape quickly, then move through mid-grits to remove scratches, and finish with fine grits that close the surface. For ceramic tile edges, a typical sequence might be diamond 120 → 200 → 400 → 800 → 1500. Skip too many steps and the previous grit’s scratches telegraph through; start too fine and you’ll spend forever chasing shape with a polish-only abrasive.

Wet work: Water carries away swarf, cools the edge, and reduces airborne silica. In glass, heat can cause checks; in ceramic, it can pull micro-chips from the body or glaze line. Keeping the surface wet also helps you see scratch patterns: a uniform sheen is your cue to move up in grit.

Angle and geometry: Glass finishers often lock their wrists and move their bodies to maintain a constant angle. Do the same on tile. Decide on your geometry—a light 45° chamfer, a shallow 30° ease, or a small pencil-round—and hold it. Consistency matters more than the exact angle, as long as it fits your design and grout plan.

Pressure and dwell: Let the abrasive do the work. Pressing harder doesn’t speed shaping; it enlarges scratches and invites chips. Instead, use even, overlapping strokes with a steady rhythm. If you hear the tone change or feel the piece chatter, back off, add water, and check the surface.

A simple way to gauge uniformity is to measure the chamfer width at three points on the tile edge—both ends and the center—using a small caliper or a marked card. Glass workers do similar checks with optical reflections; you can also hold the edge to a raking light and look for flat spots or waviness. When your scratch pattern looks even and the bevel measures consistently, you’re ready to move up a grit. Repeat until the edge is smooth to the touch and visually coherent with the rest of the installation.

Tools for clean, consistent chamfers

You don’t need a full shop to produce uniform edges; you need the right abrasives, a way to control water, and a few simple guides.

Diamond hand pads: Foam-backed diamond pads (often in 60/120/200/400/800/1500 grits) are the backbone for tile and glass edge work. They’re rigid enough to hold an angle but forgiving over minor waves. Wet/dry pads let you keep working with a spray bottle or small tray of clean water. Keep one coarse pad (120) for shaping and two or three finer pads (400–1500) for refining.

Profiling and polishing tools: For long runs or production work, a variable-speed polisher with diamond sheets or a tile profiling wheel provides speed and uniformity. On mitered edges or consistent bevels, “jolly” profiling machines act like a fence, helping you maintain an exact cut and finish. Even if you’re working by hand, a simple angle block or a scrap piece cut to your preferred bevel can act as a reference.

Support and guides: A flat, non-slip pad keeps tiles steady. Masking tape can serve as a visual stop line along the face to protect glaze and define your bevel width. Some installers use a permanent marker on the edge to reveal where material is removed; once the ink is gone uniformly, the pass is complete.

Water and cleanup: A small tray or a squeeze bottle delivers enough water to keep the edge cool and the dust down. Change water frequently; slurry can scratch. Keep microfiber towels nearby to dry and inspect between grits.

Measuring and lighting: A pocket caliper or a simple card marked in millimeters helps you spot variations. A headlamp or a movable task light gives you the raking light needed to see scratch direction and low spots.

According to a article, good workmanship shows in the details—edges that are true, grout that seats properly, and finishes that hold up. The tools above are there to make that level of quality easier to repeat, tile after tile. Choose a set you can manage comfortably; consistency beats complexity every time.

Step-by-step honing workflow

This repeatable process turns sharp, inconsistent edges into uniform, refined chamfers. Adjust the grit numbers to match your tile’s hardness and glaze.

Prep and protect: Clean the cut edge. Tape the tile face 1–2 mm from the edge to guard the glaze and to act as a visual stop. Stabilize the tile on a non-slip pad.

Set your geometry: Decide on the chamfer width—common targets are 1 mm for a crisp ease or 2–3 mm for a softer feel. Draw a light pencil line along the edge as a guide if helpful.

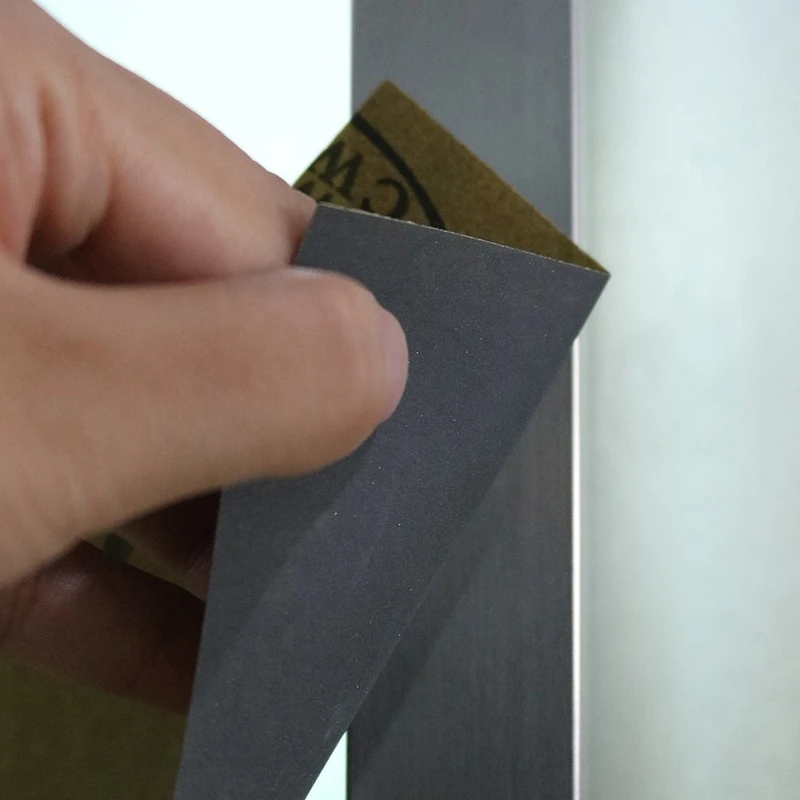

Shape with 120 grit: With the pad wet, set your angle (e.g., 45°) and make even, overlapping strokes from one end to the other. Work in passes rather than spots. Measure the bevel at both ends and the center; adjust your pressure and angle, not your speed.

Refine with 200 and 400: Rotate your stroke direction slightly at each grit to cross-hatch the scratch pattern. Don’t move up until the previous scratches are uniformly replaced. Keep the surface wet and the pressure light.

Close the surface with 800 and 1500: These grits remove haze and give a satiny finish. On glazed ceramic, you’re finishing the edge body, not trying to match the gloss of the face. Aim for a uniform sheen that looks intentional, not polished like glass.

Break the arris: Lightly ease the two tiny edges where your chamfer meets the tile faces to eliminate micro-sharpness. One or two feather-light passes with 800/1500 grit is enough.

Check and standardize: Dry the tile and inspect under raking light. Measure the bevel width. If one tile differs, go back one grit and correct. It’s faster to fix now than when tiles are installed.

Install smart: When edges meet—on a niche, bench, or curb—keep your bevel geometry consistent across all pieces. Align grout joints so the eased edges mirror each other.

Seal if needed: Most ceramic bodies don’t need edge sealing. For porous bodies or cut edges near frequent water exposure, a penetrating sealer can reduce staining. Apply sparingly and wipe the face immediately if tape was removed.

Clean and label: Rinse pads, change water, and label finished tiles by area so matched pieces stay together.

Actionable tips

Use a simple feeler gauge: A thin coin or a 1 mm plastic card makes a quick check for consistent bevel width across tiles.

Mark start/stop: Draw two small pencil marks on the tile face to show where your strokes begin and end; this prevents “over-honing” the ends.

Control speed on power tools: Keep polishers at low RPM (typically 1,500–2,000) with water feed to avoid burning and micro-chipping.

Pre-hone before cutting miters: On miters, lightly ease the raw edge after cutting to reduce chip-out during handling and grouting.

Keep a test tile: Every time you change pad brands or grit sequences, test on a scrap from the same batch to confirm the finish matches.

Troubleshooting cues

Tiny edge chips: You’re pressing too hard or working dry. Add water, lighten up, and step back one grit to remove damage.

Gray haze won’t leave: You skipped grits. Return to the last step that produced a uniform scratch and progress again in smaller jumps.

Uneven bevel width: Your angle is wandering. Use a simple angle block as a reference and slow your stroke.

Glaze scuffing: The tape line is too close or worn. Retape with a slight setback, and keep the pad square to the edge so it doesn’t roll over the face.

How To Sand — Video Guide

Hand-sanding glass is slow and demanding, and a recent tutorial on how to sand and polish a bottle shows why technique matters. The presenter highlights a realistic timeline, the value of water, and the patience needed to move through grits without skipping steps. You see careful angle control, consistent pressure, and the way each grit’s scratch pattern must fully replace the last before moving on.

Video source: How To Sand And Polish A Glass Bottle

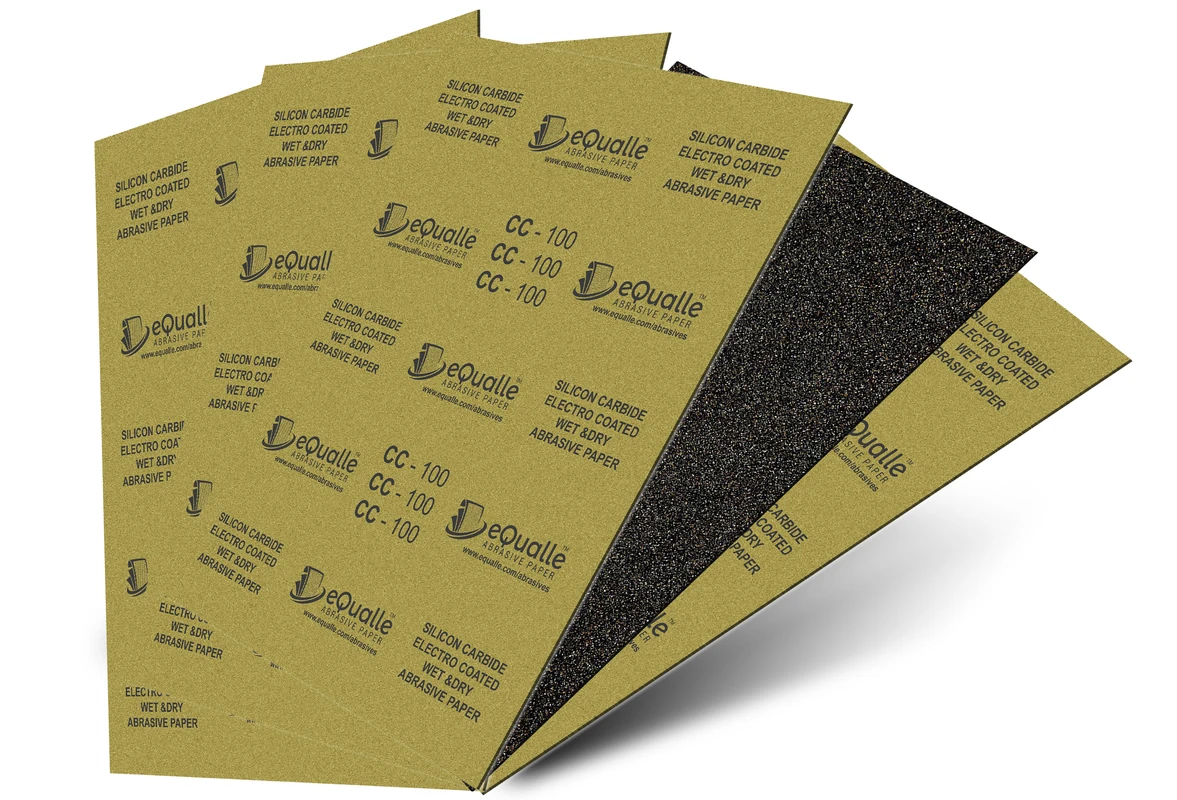

120 Grit Sandpaper Sheets (100-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Refines surfaces after coarse sanding by removing scratches from lower grits. Consistent performance on wood, drywall, and metal. Ideal for wet or dry finishing before applying primer or stain. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: What grit should I start with on ceramic tile edges?

A: Start with 120-grit diamond for shaping, then progress to 200, 400, 800, and 1500. Very hard porcelain may need a brief 80-grit pass to establish shape, but use it sparingly to avoid deep scratches.

Q: Can I achieve a uniform bevel without power tools?

A: Yes. Foam-backed diamond hand pads, water, and a stable work surface are sufficient for crisp, consistent results. Power tools help on long runs but aren’t required.

Q: How do I avoid dust and chips during honing?

A: Work wet, keep pressure light, and refresh clean water often. Wet methods reduce airborne silica and cool the edge, limiting micro-chipping along the glaze line.

Q: Should I seal the honed edges of ceramic tile?

A: Most glazed ceramic edges don’t need sealer. For porous bodies or cut edges in wet zones, a penetrating sealer can help resist staining—apply lightly and wipe immediately.

Q: How wide should my chamfer be for a modern look?

A: A narrow, consistent 0.5–1.5 mm bevel reads clean and contemporary while removing sharpness. Use a small caliper or a marked card to keep that width repeatable across tiles.