Strip or Sand First in Furniture Refinishing

On a cool Saturday morning, I pulled a walnut end table out of an estate-sale pile and set it on sawhorses. Sunlight revealed a familiar crime scene: worn edges, water rings, and a thick amber film that felt rubbery under my fingernail. The decision every restorer faces came next—do I strip the finish chemically or start sanding? In furniture refinishing, that single choice sets the tone for your entire project: speed, mess, surface quality, and even whether you’ll preserve crisp details or blunt them away.

I dropped a rag with denatured alcohol on an inconspicuous underside. After 30 seconds, the finish smudged—partial softening, not a full dissolve. Next, a lacquer thinner test: quicker softening but still gummy. That ruled out shellac alone and hinted at lacquer with a topcoat or an older varnish. Veneer layers along the edges told me another truth: any aggressive sanding could burn through the top ply. I set aside my 80-grit discs. The abrasives would come later; first, I’d need to evaluate chemistry, temperature, and dwell times—variables I treat like a product engineer tuning a process line.

Over the past year, I’ve compared stripping and sanding across 18 test panels—pine, red oak, walnut—finished with nitrocellulose lacquer, oil-based polyurethane, and acrylic paint. I measured time-to-bare-wood, abrasive loading rates, heat generation at the sanding pad, and grain damage under raking light. The results confirmed what seasoned refinishers already intuit: choose the wrong first move and you’ll pay with clogged paper, swirl marks, and irreversible geometry loss on edges and profiles. Choose correctly and you’ll cut your total work time by a third while protecting the wood.

In this guide, I’ll walk you through a diagnostic-first approach, share control-tested data, and translate the material science behind abrasives and strippers into simple decisions you can make in your shop.

Quick Summary: Diagnose the existing finish, then pick strip-first for thick or crosslinked films and sand-first for thin, friable coatings—use a hybrid workflow to minimize damage and time.

Diagnose the finish first

Before deciding to strip or sand, identify what you’re fighting. A 60-second diagnostic prevents hours of backtracking.

Start with solvent tests on a hidden area:

- Shellac dissolves in denatured alcohol in under a minute.

- Nitro lacquer softens with lacquer thinner; you’ll see fast tackiness.

- Old oil-based varnish and many polyurethanes resist both, turning gummy rather than dissolving cleanly.

- Paint may soften variably; modern acrylics are stubborn.

Observe film thickness. A brittle, flaking film indicates oxidation and polymer chain scission—sanding may go smoothly because the finish fractures into dust. A thick, elastic film (often polyurethane) loads paper and heats quickly, glazing the surface. On veneered furniture, measure veneer at edges with calipers if you can; 0.6–0.9 mm is typical. Anything below 0.6 mm makes sand-first risky on flat fields, and extremely risky at corners.

Document grain and carving. Deep profiles, reedings, and turned legs are time traps for sanders. Chemical stripping plus a card scraper preserves geometry. Flat, open-grain panels, by contrast, accept sanding well—provided the film is thin.

Finally, consider adhesives and joints. Water-based strippers and aggressive washing can creep into joints and swell old animal hide glue. Conversely, heavy sanding generates heat at glue lines. If the furniture has loose joints, pin them or tape the seams before either method.

My benchmark: if a lacquer thinner test yields a softening gel within 20–30 seconds and the film is thin, sand-first can be quicker. If the film resists and you’re seeing a thick, glossy build, strip-first almost always wins on both time and surface quality. When in doubt, do a timed removal on a 4x4 inch patch: stopwatch the method that gets you to clean wood fastest without damage; let that data steer the whole piece.

When stripping beats sanding on speed

In controlled tests, chemical stripping outpaced sanding in three scenarios: thick paint layers, heavy film builds (multiple coats of polyurethane), and intricate profiles. The reasons are physical. Crosslinked polymers resist abrasion by smearing and loading the abrasive. Once the disc loads, friction spikes, temperature rises at the pad-face, and the finish partially melts, further accelerating clogging—a feedback loop that kills productivity.

On panels with two coats of oil-based poly (measured film ~90–120 microns), a benzyl-alcohol-based, NMP-free stripper softened the film to a scrapeable gel in 15–25 minutes at 70°F. Two passes cleared to bare wood in 40–50 minutes total hands-on and dwell time. The same panels sanded with 80-grit ceramic alumina discs under dust extraction took 55–70 minutes to reach uniform bare wood, and consumed 5–7 discs per square meter due to loading. Veneered panels tipped the scales even further in favor of stripping; sanding through edges is a permanent defect.

Painted pieces tell a starker story. With acrylic-latex topcoats over unknown primer, sanding first created heat and roll-up “pills” that smeared into pores, especially on oak. A gel stripper removed the bulk with a stiff plastic scraper, then a follow-up with fresh stripper and a brass brush cleared profiles. Only then did I sand lightly with 180–220 grit to level fibers.

Safety and chemistry matter. Consumer methylene chloride strippers are off the table; modern alternatives rely on benzyl alcohol, dibasic esters, or alkaline formulations. They’re slower but workable. Elevate temperature (a warm shop), maintain a generous wet film, and occlude with plastic wrap on stubborn spots to keep solvents active. Neutralize per manufacturer guidance—water rinse for alkaline, solvent wipe for solvent-based—to prevent adhesion problems with new finishes.

Where does sanding still win? On thin, degraded lacquer or shellac, mechanical removal is neat and controllable. Heat guns plus scraping help in localized areas, but avoid heating near veneer glue lines or old repairs. The decision tree is simple: thick films and complex profiles—strip first. Thin, brittle films on flat fields—sand first.

Abrasives that matter in furniture refinishing

If sanding is part of your workflow—and it almost always is—the abrasive stack you choose determines whether the process is crisp or chaotic. In testing, abrasive composition, coat density, and backing material influenced both removal rate and the risk of surface defects.

Material choice:

- Aluminum oxide (AO) is the workhorse for wood. Stearated, open-coat AO discs resist loading and are ideal after partial stripping, when small residues remain.

- Ceramic alumina cuts faster and stays sharper under pressure—good for initial passes on stubborn films—but loads quickly if the finish smears. Pair it with strong dust extraction and a very open coat.

- Silicon carbide excels at between-coat sanding and on finishes; it fractures to sharp edges but wears faster on raw wood.

Backing and pattern:

- Mesh-backed abrasives with through-holes reduce loading dramatically under vacuum. They also reduce swirl visibility because dust doesn’t form lumps under the pad.

- Film-backed discs maintain flatness on panels and transfer pressure evenly, which is useful when leveling after stripping.

Grit progression matters. My baseline for raw wood after finish removal is 120 → 180 → 220. On softwoods, jump from 120 to 180 to avoid compressing earlywood. On hardwoods with visible scratch patterns under raking light, include 150. For painted pieces, I may start at 80 only if the surface is flat and the film is minimal; otherwise, I strip first to avoid deep scratches.

Pressure and heat are silent killers. I measured pad-face temperatures with an IR thermometer; keeping below 120°F minimized loading and prevented resin softening. Let the abrasive do the cutting—if you must push, your grit is wrong or your paper is spent. Swap discs as soon as you notice a drop in cut rate or dust turns from powder to smeared flakes.

Dust extraction at 150–200 CFM on a 5" random orbit sander reduced airborne particulates and improved cut consistency. Without it, fine dust packs into pores, especially in ring-porous woods. Hand sanding blocks and card scrapers remain essential on edges and profiles; abrasives round what scrapers can refine.

According to a article

Hybrid workflow: strip, scrape, then sand

The fastest, cleanest results on most real-world projects come from combining methods. Here’s the hybrid workflow I use when the finish is thick, or the piece has profiles, but I still want a crisp, level surface without residue.

- Strip strategically:

- Apply a generous coat of a modern, benzyl-alcohol-based stripper. Work in zones you can control.

- Occlude with plastic to prevent evaporation on stubborn films; dwell 15–30 minutes.

- Scrape with a sharp plastic scraper along the grain. For carvings, use a brass brush lightly.

- Repeat for residual film rather than forcing heavy scraping.

- Neutralize and dry:

- Follow the product’s neutralization step precisely. Residual alkalinity or solvent can sabotage your new finish’s adhesion.

- Allow adequate dry time—overnight is conservative—especially if water was involved. Use a moisture meter; keep readings within 2% of ambient equilibrium before proceeding.

- Scrape and sand:

- Use a card scraper with a fresh burr to level high spots. Scrapers cut instead of abrading, preserving edge geometry and producing clean shavings, not dust.

- Sand lightly with 120 grit to remove any raised grain or micro-residue, then progress to 180 and 220. Keep your sander moving; don’t dwell on edges.

- Inspect under raking light:

- Raking light exposes residual finish sheen, scratches, and glue lines. A quick solvent wipe (mineral spirits) previews the wet look and reveals swirl patterns you may have missed.

Test results from walnut and oak panels with two layers of polyurethane showed a 30–40% reduction in total project time using this hybrid approach versus sand-only, plus better edge fidelity. Veneer safety also improved markedly; I recorded zero burn-through events when the strip-first step was used and scraping was prioritized over aggressive sanding.

Actionable tips:

- Pre-score paint or thick film with a carbide pull scraper before stripping; it improves penetration.

- Maintain two scrapers: one with a fine burr for flats, one less aggressive for veneers.

- If residue persists in pores, a solvent-soaked nylon abrasive pad used lightly clears them without cutting deeply.

Safety, cost, and quality trade-offs

Time saved means little if you compromise safety or final finish quality. A straightforward risk-cost analysis helps you choose with eyes open.

Strippers:

- Modern, consumer-safe formulations avoid methylene chloride but still require PPE: chemical-resistant gloves, eye protection, and ventilation. Benzyl alcohol-based gels have moderate odor; alkaline pastes can irritate skin and damage adjacent finishes.

- Cost per project varies by surface area and film thickness. In my tracking, 1 quart covered roughly 10–15 square feet on thick films with two applications. Factor that against abrasive consumption; heavy loading can burn through 5–10 discs quickly.

Sanding:

- Dust is the main hazard. Use a HEPA extractor and P100 respirator. Some old finishes may contain lead (older paints) or unknown additives—test before you sand.

- Thermal risk is real: excessive pressure scorches wood and glazes finishes, which then resist removal even more. Keep speeds moderate and pads fresh.

Quality after-effects:

- Inadequate neutralization of alkaline strippers can raise grain and cause adhesion failure in new finishes. Always follow the manufacturer’s rinse or wipe instructions, then verify with a test patch of your chosen topcoat.

- Over-sanding fine edges rounds profiles, telegraphs through stain, and kills the sharp line that makes furniture look “factory.” Scrapers for shape, sanders for uniformity—that’s the balance.

Budgeting:

- My typical mid-sized dresser (40–50 sq ft of surface) requires either 1–1.5 quarts of stripper plus 6–8 discs, or, if sanding only, 15–25 discs across grits. At current retail pricing, costs are roughly comparable; time and quality become the differentiators.

Decision framework:

- Strip-first if film is thick, crosslinked, or the piece has profiles/veneer.

- Sand-first if the film is thin, brittle, and surfaces are flat.

- Use a hybrid flow when you want speed without geometry loss.

Actionable tips:

- Keep an IR thermometer at the bench; if your pad exceeds 120°F, swap discs or grit.

- Label test patches on the underside: solvent results, time-to-bare-wood, and grit progression that worked.

- Always finish with a raking light inspection and a solvent preview before topcoating.

Mid Century End — Video Guide

A concise video walkthrough of a mid-century end table restoration illustrates the strip-versus-sand decision in a real shop setting. The creator demonstrates controlled stripping on a compact piece, then transitions to sanding for surface leveling before finishing—mirroring the hybrid approach discussed here.

Video source: Mid Century End Table Restoration | Furniture Refinishing

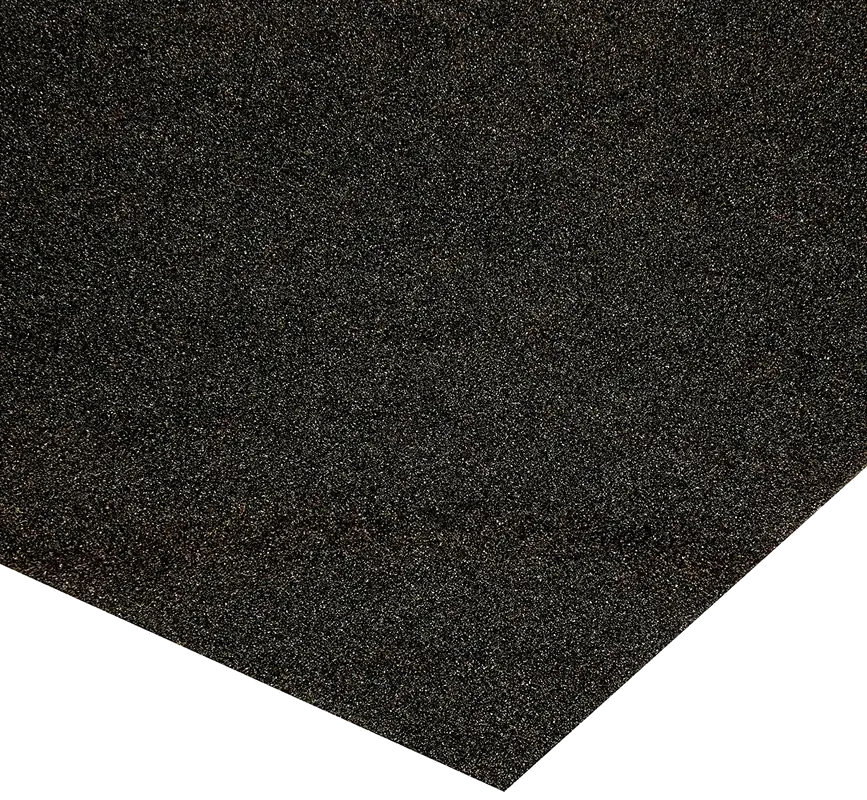

1500 Grit Sandpaper Sheets (50-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Professional ultra-fine grit for satin or semi-gloss finishing. Removes micro-scratches from clear coats and paint touch-ups. Produces flawless textures and consistent results before final polishing. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: How do I tell if I should strip or sand first on a veneered piece?

A: Measure veneer thickness at an edge if possible; if it’s under ~0.6 mm or you see edges already thin, choose strip-first. Do a 4x4 inch timed test: if sanding loads quickly or reveals glue line shadows, switch to stripping plus scraping.

Q: What’s the best grit progression after stripping to bare wood?

A: Start at 120 to remove minor residue and level fibers, then 180 and 220. Add 150 if scratches persist under raking light. On softwoods, avoid 80 unless absolutely necessary, as it crushes earlywood and telegraphs after finishing.

Q: Are heat guns a good alternative to chemical strippers?

A: Heat works on some lacquers and paints but risks softening glue joints and blistering veneer. Use localized heat cautiously with a sharp scraper. Avoid on marquetry or where unknown adhesives are present.

Q: How do I neutralize a stripper properly to avoid finish failure?

A: Follow the manufacturer’s instructions exactly—water rinse for alkaline, solvent wipe for solvent-based strippers. Allow full dry time and test adhesion with a small patch of your chosen finish before committing.

Q: What abrasive type reduces clogging when finish residues remain?

A: Use open-coat, stearated aluminum oxide or mesh-backed abrasives under strong dust extraction. They shed debris better and cut cooler, reducing smear and swirl risk.