Safer Wipe-Down Solvents and Eco Sandpaper Guide

I still remember the first evening I promised myself I’d stop ending shop days with a solvent headache. The project was a walnut credenza destined for our living room, and I wanted it to glow—clean pores, a silky hand, and a finish that would hold up to stray toy cars and weekend dust-offs. I reached for eco sandpaper, the vac humming softly, the pad skating from 150 to 180 grit like I’d planned. Then came the wipe-down, the moment everything either goes beautifully right or annoyingly wrong. I used to grab whatever was closest—mineral spirits, naphtha, alcohol—without a second thought. That’s when the trouble starts: reactivated dyes, smeared filler, hazing that didn’t show up until the first coat.

These days I prep differently. I pick the solvent by substrate and finish, not habit. I let flash-off times be as sacred as my grits. I consider the whole workflow—sanding, vacuum, wipe-down—and how to keep fumes low and residues out of the finish. If you’ve ever battled fisheyes, witness marks, or odd cure times, you know what I mean. Safer wipe-down choices aren’t about being precious; they’re about control. Control of what touches your material, what lingers on it, and what evaporates before you brush, spray, or wipe on that first coat. As a fabricator who works in both a small urban shop and on-job sites with limited ventilation, I’ve fine-tuned a set of wipe-down solvents and protocols that keep the air friendlier and the finish cleaner. Whether you’re tuning a guitar neck, prepping a steel handrail, or getting a waterborne topcoat to level on kitchen doors, this is how to choose smarter solvents—and pair them with prep methods and eco sandpaper—to get predictable, pro-grade results without the harsh hangover.

Quick Summary: Choose wipe-down solvents by substrate and finish, control evaporation and residue, pair with clean sanding and rags, and prioritize safer, low-odor options for consistent, flaw-free coatings.

Why wipe-down solvents matter

A wipe-down isn’t housekeeping; it’s a performance-critical step that determines whether your finish will bond, level, and cure as intended. Dust isn’t your only enemy. Skin oils, machine lubricants, silicone from polishes, and airborne shop grime all interfere with adhesion and surface tension. Get the wipe-down wrong and you’ll see fisheyes that crater your topcoat, dull patches from reflowed contaminants, or unpredictable cure times that gum your sandpaper between coats.

Safer solvent choice starts with understanding two factors: what you’re removing and what you’re about to apply. Oil-based contaminants respond well to aliphatic hydrocarbons (odorless mineral spirits) or citrus-based d-limonene cleaners. Polar contaminants—like water-soluble shop residues or shellac dust—tend to lift with alcohol or water with a mild surfactant. The wrong solvent can dissolve, smear, or embed the very contamination you’re trying to remove. Acetone, for example, flashes fast and cuts hard but can drive residues into open grain and soften plastics. Naphtha is fast and effective but higher on the flammability spectrum. Both can be overkill for many woodworking tasks.

Ventilation and residue are equally important. A “clean” wipe-down doesn’t leave behind a film that competes with your finish. That’s why I favor isopropyl alcohol (IPA, 70–91%) and low-odor mineral spirits (OMS) for general woodworking: they’re predictable and leave minimal residue when used properly. For waterborne finishes, I often use IPA or a water-and-surfactant wipe followed by a distilled water rinse to avoid surfactant bleed that can cause cratering later.

Finally, the timing matters. Wipe too close to coating and residual solvent can interfere with flow and cure. Rush the job on a cold day and evaporation slows, pulling contaminants across the surface just as you lay down your first coat. Respect flash-off and you’ll see the reward in a glassy first pass.

Match solvent to substrate and finish

The safest choice is the one that removes what you need without compromising the material or the coating system. Think in pairings.

Wood:

- Raw hardwoods (oak, ash, walnut): After sanding, vacuum thoroughly. Use IPA for a final wipe if you’re applying waterborne finishes, or OMS before oil-based finishes. Skip water wipes on open-pored woods unless you plan to raise the grain intentionally.

- Resinous softwoods (pine, fir): Pitch can smear. Use OMS to lift resin, then a clean dry towel. Alcohol can flash too quickly and redistribute resin.

- Oily exotics (teak, ipe): Wipe with naphtha or OMS to cut natural oils; allow extra flash time. For epoxy or polyurethane adhesives, scrub with alcohol after a light scuff to boost bond.

Metal:

- Bare steel: Degrease with a citrus cleaner or OMS; follow with IPA. For powder-coat prep, use a dedicated panel wipe compatible with the coating system. Avoid water-only wipes unless you dry with heat to prevent flash rust.

- Aluminum: Prefer alcohol or panel wipe. Avoid strong alkaline degreasers that can etch the surface unless you’re following a specific prep system.

Plastics and composites:

- Acrylic, polycarbonate: Use 70% IPA and a light touch. Strong solvents can craze or fog these surfaces. For epoxy laminates, IPA or acetone sparingly—test first.

- Fiberglass gelcoat: Naphtha or panel wipe works; rinse with IPA for waterborne systems.

Finish compatibility:

- Waterborne topcoats: Lean towards IPA or distilled water with a drop of dish soap, then a water rinse. Avoid heavy hydrocarbon residues.

- Oil-based varnish/poly: OMS is the safer workhorse. Naphtha if you need a faster flash and lower residue before spraying.

- Shellac: Alcohol-friendly. A final alcohol wipe is ideal.

- Lacquer: Fast-evaporation solvents (naphtha, acetone) are common, but keep exposure minimal and test for lifting on existing coatings.

Strive for the mildest effective approach: remove contamination, don’t move it around, and don’t compromise what the finish needs to adhere.

Surface prep with eco sandpaper and rags

Wipe-downs work best on a surface that’s already well-sanded and dust-managed. That’s where eco sandpaper shines—abrasives made with recycled paper backings, plant-based or waterborne resins, and stearate-free coatings that reduce gumming without leaving waxy films. I keep a dedicated stack from 120 through 320, paired with a vacuum sander and clean, low-lint rags.

My sanding method is straightforward: shape with 80–120 as needed, refine to 150–180 for oil-based finishes, and up to 220–320 for waterborne to control raised grain. Between grits, vacuum aggressively and wipe with a dry microfiber. That reduces how much your solvent wipe must do, which is the safest possible approach—less chemical, more control.

Use the right rag. Cotton T-shirt rags can shed and carry silicone from the laundry. I prefer colorfast, low-lint microfiber cloths or dedicated finishing wipes stored in a sealed bin. Fold them into a thick pad and rotate to a clean face frequently. Solvent-saturated rags can streak; barely damp is better.

Four actionable prep tips:

- Always sand a grit lower than you think on open-pore woods, then burnish with the final grit. This keeps solvent from dragging fines into the pores.

- Pre-raise the grain for waterborne finishes: mist with distilled water, let dry, then sand lightly with 220 eco sandpaper. Your final wipe can be just IPA; no need for water again.

- De-static before the last wipe: a pass with a grounded vacuum hose or an anti-static wipe reduces dust attraction, so your solvent wipe doesn’t become a dust mop.

- For metal, finish with a maroon non-woven abrasive and then 320 paper in one direction. Your wipe-down will lift the powder, not smear it.

According to a article, some modern coatings are solvent-free, which underscores the value of clean mechanical prep—you can often do more with careful sanding and less with aggressive cleaners. That shift toward lower-tox workflows is where your technique pays off.

Safer solvent lineup: my go-to picks

I sort wipe-down choices by strength, residue, and volatility. Here’s the short list I reach for first, in ascending order of bite.

Distilled water + a drop of mild dish soap: Safe and effective for water-soluble grime on sealed surfaces or pre-finish raised-grain steps. Always follow with a clean water rinse and dry cloth. Avoid on raw steel unless you can heat-dry to prevent rust.

Isopropyl alcohol (70–91%): My default for waterborne finishes and plastics. It evaporates predictably and leaves very little residue. 70% cuts salts and sugars well; 91% flashes faster. Keep away from open flames and ventilate—low odor isn’t no risk.

Odorless mineral spirits (OMS): The woodworking workhorse for oil-based finishes. Lower aromatic content means fewer fumes. Cuts oil and grease, gives you a longer working time to lift contaminants into the rag, and leaves minimal residue when applied sparingly.

Citrus-based cleaners (d-limonene): Great for heavy shop grime, adhesive ghosting, and greasy fingerprints. Apply, dwell a minute, then remove with a clean rag and follow with IPA to knock down any oily remnants. Pleasant smell, still flammable—treat with respect.

Naphtha: Fast-evaporating hydrocarbon. Good when you need a quick degrease before spraying or bonding, particularly on oily woods. Use sparingly and ensure thorough ventilation. Don’t use near adhesives that can soften or smear.

Acetone: The scalpel—powerful, super fast, and unforgiving. I reserve it for epoxy prep, stubborn contamination, or metal where paint systems recommend it. Can swell plastics and drive contaminants into wood pores if you flood. Spot test first.

Denatured alcohol (ethanol blends): Effective with shellac systems and some panel wipes for automotive finishes. Denaturants vary; pick products labeled low-methanol where available, and ventilate well.

Three practical selection rules:

- Like dissolves like: oily contamination = OMS or naphtha; polar contamination = alcohol or water/surfactant.

- Start milder, escalate only if necessary: if IPA lifts the contamination, you don’t need acetone.

- Pair the wipe to the finish: waterborne topcoats prefer IPA/water-prepped substrates; oil-based finishes tolerate OMS-prepped surfaces better.

Step-by-step wipe-down protocols

A good protocol is repeatable. I run variations of the same steps whether I’m finishing a maple tabletop or prepping a steel bracket.

Wood with waterborne finish:

- Sand progressively to 220–320. Vacuum thoroughly.

- Pre-raise the grain with distilled water; dry 30–60 minutes or accelerate with gentle heat.

- Sand lightly with 320 eco sandpaper. Vacuum and de-static.

- Wipe with 70–91% IPA using a folded microfiber, just damp, not wet. Rotate to a clean face frequently.

- Flash-off 10–20 minutes (longer in cool, humid conditions). Inspect with raking light; if you see smears, switch cloths and repeat.

- Apply the first coat within 2 hours to avoid airborne contamination.

Wood with oil-based varnish/poly:

- Sand to 180–220. Vacuum and wipe dry.

- Spot-clean resin or fingerprints with OMS; avoid flooding end grain.

- Final wipe-down with fresh OMS on a clean cloth, then lightly buff with a dry cloth to pick up any residual solvent.

- Flash 20–30 minutes until odor significantly subsides and the surface looks uniformly dry. Begin coating.

Oily exotics (teak, ipe) for adhesive or varnish:

- Sand 120–150, vacuum.

- Wipe with naphtha. Let flash fully—15–30 minutes.

- Repeat a second light wipe just before adhesive or first coat. Time your application so natural oils don’t surface again.

Bare steel for paint:

- Abrade with maroon non-woven, then 320 in one direction.

- Degrease with citrus cleaner; dwell 1–2 minutes. Wipe off.

- Follow with IPA to remove any citrus residue.

- Dry thoroughly; if humidity is high, warm the part with a heat gun briefly to prevent flash rust.

- Prime as recommended.

Powder-coated or prefinished surfaces for touch-up:

- Clean with water + mild soap. Rinse and dry.

- Lightly scuff with 320–400 eco sandpaper.

- Wipe with panel wipe or IPA, flash 10 minutes, then touch up.

Time discipline is key. Set a timer for flash-off so you’re not guessing. And always test on an inconspicuous spot when switching solvents mid-project.

Ventilation, PPE, and waste disposal

“Safer” doesn’t mean “harmless.” Even low-odor solvents demand good airflow, skin protection, and a plan for rags and waste. In my shop, I treat wipe-downs like mini spray sessions.

Ventilation:

- Move air across and out, not straight at your work. A box fan pulling through a window with a clean intake on the opposite side of the room is better than a fan blasting at your surface.

- In cold weather, cycle short bursts: ventilate hard during wipe-down and flash-off, then close up to stabilize temps for coating.

PPE:

- Nitrile gloves, not latex—nitrile resists hydrocarbons better. Change gloves when they get wet; saturated gloves smear contamination.

- Safety glasses are non-negotiable. Alcohol and acetone splash easily.

- For heavy wipe-downs in small spaces, use a half-mask respirator with organic vapor cartridges. For light IPA-only work in a well-ventilated area, I still keep the mask nearby.

Rags and spontaneous combustion:

- Oil and solvent rags belong in a sealed metal can. For oil-based finishes that cure oxidatively (linseed, tung blends), lay rags flat to dry outdoors before disposal or submerge in water inside the can until hazardous waste drop-off.

- Don’t ball rags up in a corner. That’s how you get a 3 a.m. fire call.

- Label waste containers and schedule regular drop-offs at your local hazardous waste facility.

Spills and storage:

- Store solvents in approved containers, away from heaters or pilot lights.

- Keep a spill kit with absorbent pads and a disposal plan. If you knock over a quart of naphtha, you’ll want a procedure, not a panic.

These safety habits are muscle memory after a few sessions—and they’re what allow you to use modest, effective solvents confidently instead of reaching for the harshest thing on the shelf.

Ask The Pool — Video Guide

There’s a helpful clip from the pool-building world that tackles a familiar question: why a cured surface sometimes feels like sandpaper. In it, a pro explains how an eco-style finish can develop grit-like texture when application conditions, substrate prep, or curing don’t line up, and how to address it without tearing everything back to square one.

Video source: Ask The Pool Guy: Why does my ecoFinish feel like sandpaper?

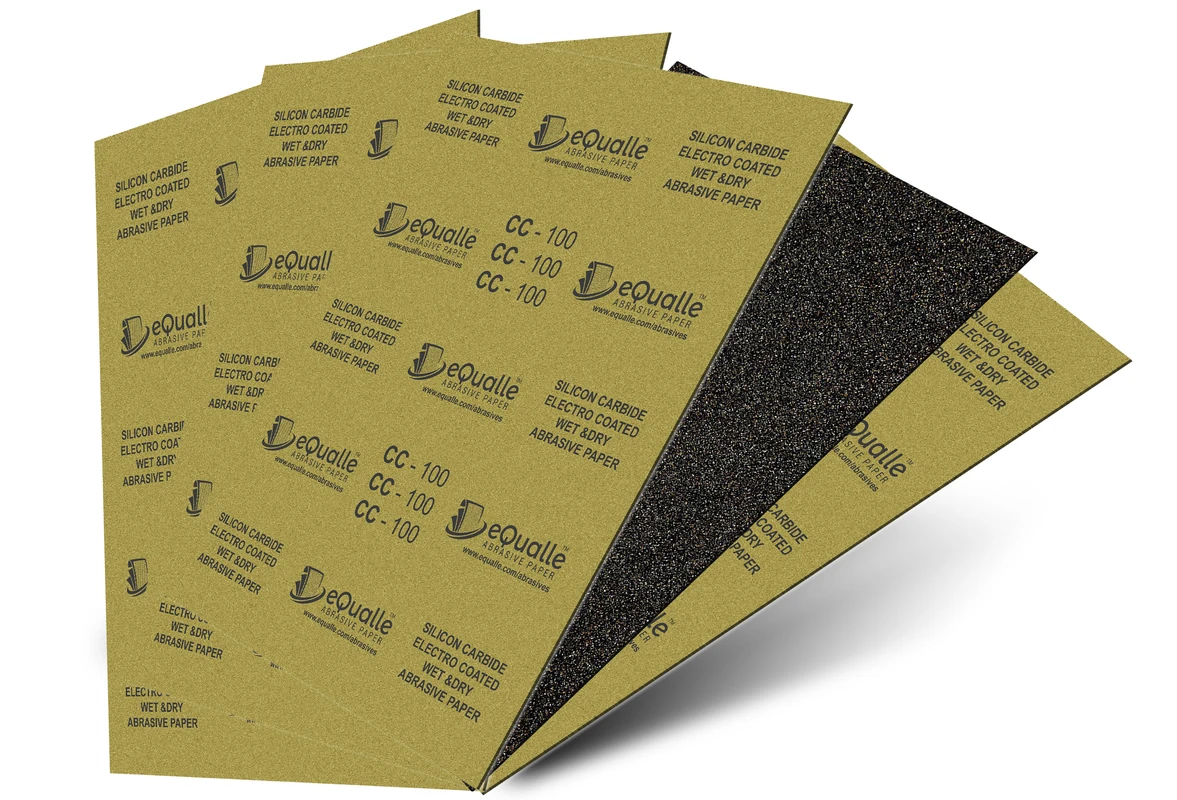

320 Grit Sandpaper Sheets (50-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Precision finishing grit that enhances clarity between paint or lacquer coats, ensuring a flawless final layer. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: Can I just use vinegar and water for wipe-downs before finishing?

A: Not recommended on raw surfaces. Vinegar is acidic and can etch metal or react with woods high in tannins, potentially affecting color. For waterborne finishes, use distilled water with a drop of mild soap followed by a clean water rinse, or go with 70–91% isopropyl alcohol.

Q: What’s the practical difference between OMS and naphtha for wood prep?

A: OMS evaporates slower, giving you time to lift oils into the rag and leaving minimal residue—great for oil-based finishes. Naphtha flashes fast and is useful on oily woods or when you’re spraying soon, but requires attentive ventilation and can be too aggressive for some plastics.

Q: Do alcohol wipes leave anything behind that can affect waterborne finishes?

A: High-purity IPA leaves very little residue when you use clean, low-lint cloths and allow full flash-off. Avoid denatured alcohols with unknown additives unless you’ve tested them. When in doubt, a final light pass with distilled water can remove trace residues.

Q: Should I wipe before or after final sanding?

A: After. Sand, vacuum, de-static, then perform your final wipe-down. If you must spot-clean mid-sanding (e.g., resin pockets), let the solvent flash fully and then sand again one grit lower to avoid witness marks.

Q: Where does eco sandpaper make the biggest difference?

A: In the final grits and between-coat scuffing. Quality eco sandpaper with consistent abrasive and clean binders reduces loading and cuts predictably, so your wipe-down removes less debris and you get fewer contaminant streaks in the first coat.