Clear Coat Leveling: Flatten Texture, Save Basecoat

You know the moment: the car looks incredible under garage lights, glossy and deep. But then you pull into bright midday sun and see the texture—orange peel, a few dust nibs, maybe a mild wave on a hood that deserves to be glass-smooth. Your stomach drops. You want that mirror finish, yet the fear of sanding through the high spots into basecoat is real. It’s not just about shine; it’s about preserving the integrity (and value) of the paint system. That’s where clear coat leveling comes in—methodical, careful, and entirely achievable with the right approach.

I still remember a client who had babyed their vehicle through a full repaint. The color was stunning, but the clear had just enough texture that the car didn’t “read” as premium in sunlight. Their biggest worry matched most DIYers: “I’ve seen horror stories of burn-throughs on edges. Is it safer to just leave it?” We walked the line together—literally—taping every edge, mapping the high spots, and creating a plan to flatten texture without compromising the base. When we finished, the panel didn’t just look glossy; it felt tension-free to the eye. No waves, no orange peel—just a calm, uninterrupted reflection. That experience informed the process you’re about to read.

Think of this as craft more than correction. You’re not removing defects at any cost; you’re managing risk, protecting film build, and achieving precision. We’ll cover how to read the surface, select tools that lower your margin of error, and follow a step-by-step system for sanding and polishing that stops short of danger. Done right, clear coat leveling is less about aggression and more about restraint.

Quick Summary: You can safely flatten clear texture by measuring film, mapping risk zones, using cushioned abrasives and controlled passes, and stopping as soon as the texture is leveled—not when all scratches are gone.

Reading the surface without risking through-cuts

Before a single abrasive touches paint, your goal is to understand what the surface is telling you. Texture isn’t uniform; some panels will show tight, pebbly orange peel, while others have larger, rolling undulations. High spots—ridges, edges, body lines, and raised details—are where burn-throughs happen. Reading them clearly is the difference between masterful leveling and costly repair.

Start with lighting. Use a high-CRI handheld light at a shallow angle to exaggerate texture and track your work. A polarized light or even sunlight reflection can reveal high ridges. Mark the danger zones with removable wax pencil or low-tack tape—edges, sharp creases, emblem surrounds, and any area with prior repair.

Next, measure. A paint thickness gauge (ideally one that reads microns on both steel and aluminum) is essential. While gauges don’t isolate clear coat thickness, trends matter. If the hood averages 120 µm and a corner reads 85 µm, that’s a warning. Many OEM clears fall around 40–60 µm of the total stack; safe, targeted leveling often removes 3–8 µm. That isn’t much margin.

Use a guide coat. A dusting of a contrasting dry guide coat—or a wax pencil grid—helps visualize high/low areas as you sand. The highs lose color first; if a high fades quickly, adjust pressure or skip to a softer interface.

Actionable tips:

- Tape all edges, badges, and body lines with 3–4 layers of high-quality masking tape; remove a layer only for the final refinement.

- Use a cushioned interface pad with your DA sander to soften pressure on peaks.

- Begin with 3000 grit in test spots; only step coarser if leveling stalls.

- Keep a running tally of passes and micrometer readings for each zone.

Remember: flattening texture is a stop-early exercise. It’s perfectly fine to leave a hint of peel near edges if it preserves your basecoat.

Tools and media for clear coat leveling

The right tools make the process predictable and forgiving. Your core kit should include a dual-action (DA) sander with variable speed, quality sanding discs and foam-backed abrasives, interface pads, a paint thickness gauge, masking tape, and controlled lighting. For hand work, have soft foam blocks and micro-sanding sticks for tight areas.

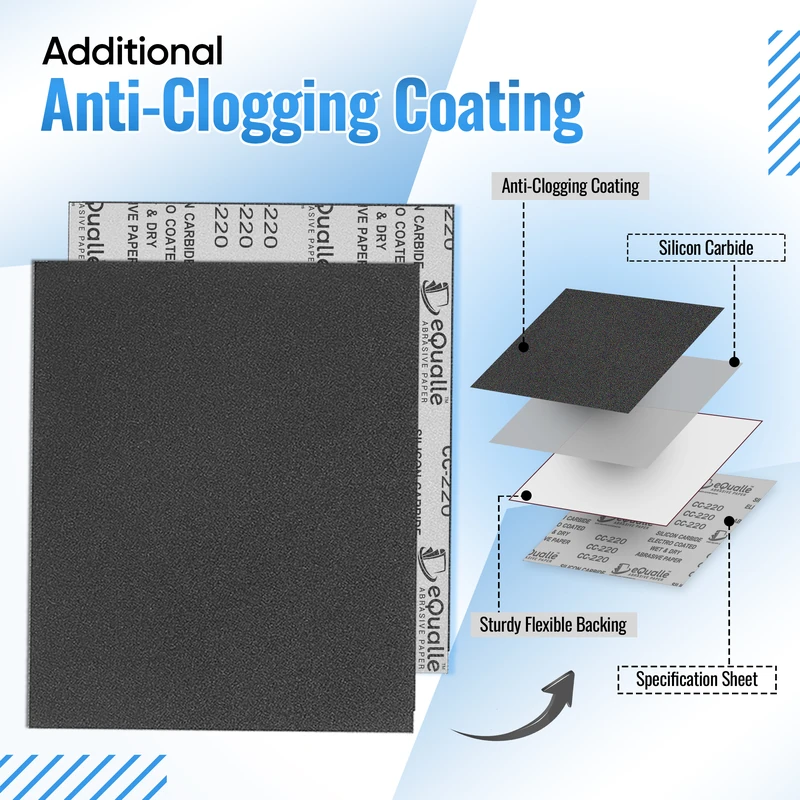

Abrasive selection sets the tone. Start as fine as you can while still seeing progress. Foam-backed 2000–3000 grit discs and 3000–5000 finishing films reduce cut at high spots because their cushion conforms slightly. For stubborn orange peel on thick clears (e.g., some repaints), you might test 1500 foam-backed on a small, safe area—but only after measuring and taping aggressively. Always follow coarse cuts with 3000–5000 to reduce scratch depth, which makes polishing safer and quicker.

Lubrication matters. Use clean water with a drop of car wash soap or a dedicated sanding lubricant to keep the paper cutting cool and uniform. Frequently rinse discs and wipe the panel to prevent loading and rogue scratches. A soft squeegee is invaluable: it pulls water away so you can inspect the surface after each short set of passes.

Interface pads are your insurance. A 5 mm foam interface on a DA spreads pressure, so the disc doesn’t bite peaks too hard. For flatter zones needing more cut, a thinner interface (2–3 mm) balances safety with effectiveness. For hand sanding, a dense foam block keeps contact even across a small area.

According to a article. The insight is universal: the smoother you make a surface before finishing, the less work it takes to achieve a flawless final appearance—and the lower your risk during refinement.

Practical setup:

- DA sander at low-to-medium speed (3–4 on many units) to prevent edge digging.

- 5-inch discs for most panels; 3-inch for pillars and bumpers.

- Foam-backed 2000, 3000, and 5000 grits; finishing films for consistency.

- Two buckets: one for clean lube solution, one for disc rinsing.

Step-by-step sanding that stops before the base

This is a conservative, repeatable sequence designed to flatten texture while preserving the basecoat. Adjust only after testing and measuring.

- Map and protect

- Wash and decontaminate the panel (iron remover and clay if needed).

- Tape edges, creases, seams, and adjacent trim with multiple layers.

- Mark high-risk zones and apply a dry guide coat or wax pencil grid.

- Test spot with the least cut

- Start with 3000 foam-backed discs on a DA with a 5 mm interface.

- Light, even pressure; 2–3 slow overlapping passes in a crosshatch pattern.

- Squeegee dry and inspect. If the guide coat and topmost peel peaks are reducing, continue with 3000 and be patient.

- Step coarser only if needed

- If 3000 barely moves the texture and you have film build to spare, test 2000 foam-backed on a 12" x 12" area, still with a cushion pad.

- Re-measure after one set of passes; track removal. Remember that 1–2 µm can be the difference between safe and risky near edges.

- Refine and blend

- Once the texture is flattened to your satisfaction, move to 5000 grit to refine scratches for easier polishing.

- Feather toward edges with hand sanding on a soft block using 3000, then 5000, keeping tape in place. You’re blending, not cutting.

- Special handling for high spots and nibs

- For a dust nib, a nib file or tiny 2000-grit sanding square on a soft stick targets the defect without thinning surrounding clear.

- Avoid direct machine sanding on sharp peaks; use hand methods and leave micro-texture if film is thin.

- Inspection cadence

- After every short set (2–3 passes), stop, squeegee, and read the surface under angled light.

- If you see the texture islands almost gone, switch to refinement even if some micro-peel remains. The goal is flatness without over-thinning.

Actionable tips:

- Use a paint depth gauge trend line: if one area drops more than 5–7 µm compared to neighbors, stop cutting there.

- Keep working sections small (no larger than 2’ x 2’) for control.

- Replace discs the moment they lose bite; dull abrasives push heat and risk.

Polishing and protection after leveling

Once the clear is leveled and refined to 3000–5000, polishing restores optical clarity. Choose compounds that match your scratch profile and pad system, then proceed with temperature, pressure, and speed in mind.

Start with a medium-cut compound on a dual-action polisher and a microfiber or foam cutting pad. Test light pressure and moderate speed first; modern diminishing abrasives can remove 3000–5000 grit marks efficiently without resorting to aggressive rotary action. If your test spot needs more bite, try microfiber; if it finishes with haze, follow with a fine polish on a soft foam finishing pad.

Heat control is vital. After leveling, the clear is thinner than before. Keep the machine moving, avoid lingering on edges, and touch the panel often—warm is fine, hot is not. If you taped edges for sanding, keep them taped for compounding; remove a layer only for the final finishing step and use hand application near body lines.

After polishing, wipe down with an IPA panel prep to remove fillers and confirm true clarity. Inspect under varied lighting—sunlight, handhelds, and indoor ambient—to ensure no haze or holograms.

Protection choices:

- Sealant: Easy to apply, adds slickness and short-term protection.

- Ceramic coating: Greater chemical and UV resistance; highlights the glassy look you just created.

- Paint protection film (PPF): For high-impact zones; apply only on fully cured finishes and after a clean, polish-free surface is confirmed.

Final checks:

- Verify uniform reflections across the panel; small “saddle” distortions can signal uneven leveling.

- Re-measure film thickness for your records; note areas where you intentionally stopped early for safety.

- Schedule gentle maintenance: pH-neutral washes, soft mitts, and minimal mechanical abrasion to preserve the leveled surface.

Actionable tips:

- Two-step polish is often enough after 5000 grit: medium cut + fine finish.

- Clean pads frequently; loaded pads run hot and haze.

- Use a finishing foam cone by hand around door handles and mirror bases to avoid thin-spot risk.

How to Clearcoat — Video Guide

If you’d like to see careful leveling in practice—on a surface where precision is everything—there’s a helpful video that documents repairing an electromechanical pinball playfield with a two-part clear. The creator demonstrates how to build and level clear over inserts, showing the same patient pacing and inspection rhythm required on automotive panels.

Video source: How to Clearcoat a Playfield Pt 4 - Leveling Inserts with 2PAC - How To Repair EM Pinball Machines

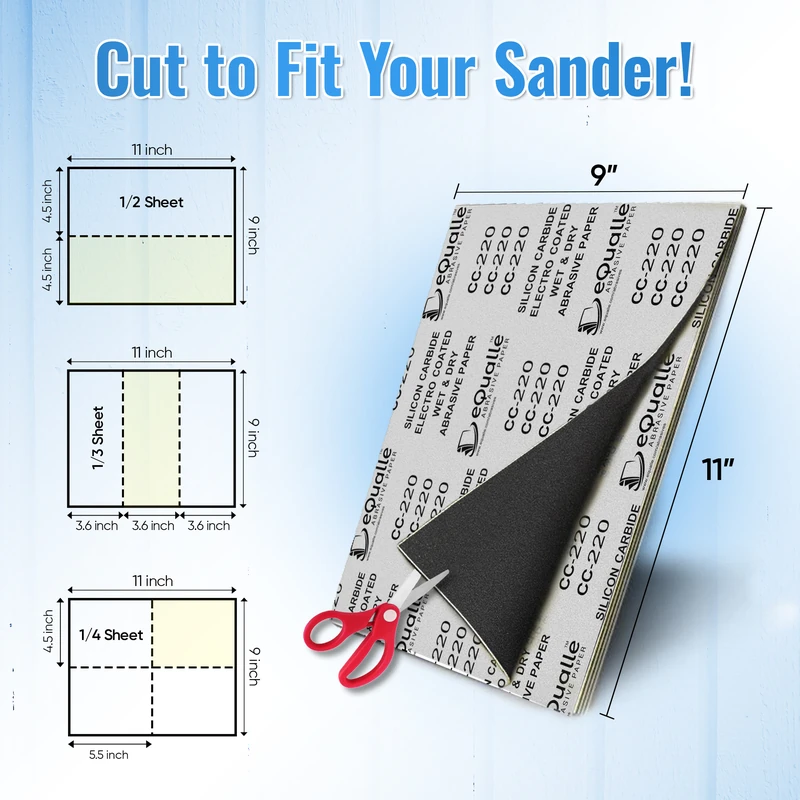

100 Grit Sandpaper Sheets (25-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — General-purpose coarse sandpaper for smoothing rough surfaces and removing old coatings. Works well on wood, metal, and resin projects. Designed for wet or dry sanding between aggressive 80 grit and finer 150 grit stages. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: How do I know if I have enough clear to level safely?

A: Use a paint thickness gauge to establish averages for the panel and compare readings across zones. If you see unusually low values or large variation (e.g., 120 µm average but 85 µm at an edge), avoid aggressive cutting there. Assume clear is 40–60 µm of total film; plan to remove the least amount needed—often 3–8 µm—with extra caution on edges and body lines.

Q: Is it ever safe to start at 1500 grit on orange peel?

A: Only after testing with 3000 and 2000 shows inadequate progress and your measurements confirm generous film build. If you do start at 1500, choose foam-backed discs with a soft interface, limit to small sections, and refine promptly to 3000–5000. For thin areas, prioritize 3000 and patience over speed.

Q: Can I level by hand instead of using a DA sander?

A: Yes—hand sanding with a soft foam block gives excellent control near edges, creases, and tight zones. Keep strokes short, use a guide coat, and work in crosshatch patterns. However, a DA with an interface pad provides more uniform results on larger flat areas and typically leaves a more consistent scratch that polishes faster.

Q: How do I prevent burning through on high spots?

A: Stack protection: double or triple tape edges, use cushioned abrasives, lower machine speed, and minimize pressure. Approach peaks and body lines with hand sanding only, refine more than you cut, and leave a hint of texture at the thinnest zones. Inspect after every 2–3 passes.

Q: After leveling, what polish system should I use?

A: Match to your refinement. After 5000 grit, a medium-cut compound on microfiber or firm foam followed by a fine finishing polish on soft foam typically restores full clarity. Always test least aggressive first, watch panel temps, and confirm with IPA wipe-downs under multiple light sources.