Feather-Edging Old Paint: Pro auto body sanding

Saturday morning, the garage is cool and quiet except for the soft hiss of the compressor winding down and the rattle of a block sander in my hand. The old pickup in front of me has stories baked into every panel—sun-faded lacquer, a few driveway dings, and a repair line from years ago that catches the light like a ridge on a map. If you’ve ever repainted a panel only to see a ghost ring around your repair, you know the sting. You steal a glance sideways under the shop light and there it is—the “step.” That’s the moment when real craftsmanship starts. The difference between an amateur patch and a pro-level finish often comes down to feather edging: the controlled, patient art of tapering layers of old paint so the transition becomes invisible. This is the heart of auto body sanding—hands, eyes, and feel coming together—where you earn that invisible blend long before the spray gun ever leaves the rack.

As a workshop guy, I’ve been in this exact spot more times than I can count: finger pads dusted with guide coat, elbow telling me when the block’s loading up, and that little voice reminding me to let the paper do the work. Feather edging is not just “sanding until smooth.” It’s understanding how coatings stack—OEM primer, color, clear, re-sprays on top—and controlling the slope where one ends and the next begins. Picture a small chip surrounded by paint build; our job is to erase the hard cliff and replace it with a long, gentle shoreline. When you get it right, you can run a fingertip across your repair with your eyes closed and not feel a thing. Today, I’ll give you the exact setup, grit choices, and block techniques I use to knock down edges without telegraphing lines into the final paint, whether you’re tuning up a daily driver or prepping a full restoration.

Quick Summary: Feather edging is the controlled tapering of old paint layers using the right grits, blocks, and guide coats to create a smooth, step-free foundation for primer and paint.

What Feather‑Edging Really Means

Feather edging means tapering old coatings so the edge between damaged or removed paint and surrounding finish transitions gradually—no cliffs, no ridges, no halos. Think of your panel as layers: substrate (metal or plastic), OEM primer, color, clear, plus any previous repair materials. A chip or sand-through creates a “hard edge” where one layer stops abruptly. Our goal is to stretch that edge into a long bevel, distributing the change over distance so your eyes, fingers, and eventually the paint film can’t detect it.

The most common reason you see steps after painting is an abrupt grit jump or a bevel that’s too short. If you cut a chip with 80 grit and jump straight to 320, you’ve removed the edge but left deep scratches under a finer finish. Under paint, those scratches swell and catch the light. Likewise, if you feather only 1/8 inch around the damage, the transition is too abrupt, and you’ll see a ghost line after primer shrinks.

Two senses matter more than any sanding chart: feel and light. After a first pass, close your eyes and sweep a clean fingertip across the repair. If you can locate the edge instantly, it isn’t feathered enough. Then, use raking light—move the panel under a low-angle light source to hunt for ridges and “islands” of uncut paint. Finally, use a dry guide coat. Dusting a contrasting powder over the area highlights highs and lows; as you sand in a crosshatch pattern, the guide coat reveals where you’re touching and where you’re not.

A proper feather edge has three traits:

- Length: The bevel extends far enough to hide the transition (often 1–3 inches around the defect).

- Progression: Each grit removes the previous grit’s scratches completely—no skipping.

- Control: Shape is driven by block choice and pressure, not finger dents or wobbles.

Master those, and your primer will lay flat, sand quickly, and paint will flow without telegraphing old edges.

Dialing in grits for auto body sanding

Grit choice is where most feather-edge issues start. You need enough bite to flatten the high edge quickly, then a sensible progression to erase scratches and refine the bevel. Here’s a reliable framework I use in the shop.

For old paint edges and chips:

- Start with 120 or 150 grit on a firm yet slightly cushioned block to shape the bevel without gouging. If the coating is very hard or thick, you can begin at 100–120 but stay off the bare metal until you soften the edge.

- Progress to 180 grit to even out the slope and remove 120 scratches.

- Refine with 220–240 to prep the area for filler or epoxy if needed.

- Before primer, step to 320–400 to keep primer film build efficient and prevent scratch telegraphing.

For filler or glazing putty:

- Shape with 80–120 on a block that matches the panel curvature.

- Smooth with 180–220.

- Finish at 320 before primer to avoid loading and to keep the feather clean.

For primer surfacer:

- Dry sand 320–400 on a block for flat areas, 500–600 on contours or for wet-sanding before basecoat.

Key principles for grit progression:

- Don’t skip more than 1–2 steps. 120 → 180 → 240 → 320 is safer than 120 → 320.

- Keep a consistent crosshatch. Change direction 45–90 degrees with each grit so you can confirm you’ve removed the previous pattern.

- Use interface pads on a DA only when you’re beyond 180 grit and want to prevent edge-bite; avoid DA on the initial cut close to edges to prevent waves.

- If you expose metal, stop with coarse grits. Seal with epoxy before building primer to prevent corrosion and edge swelling.

Three quick tips:

- Dry guide coat every step. It’s cheap insurance that you’re not dragging hidden scratches into primer.

- Change paper sooner than you think. Dull abrasive heats the panel and polishes instead of cuts, exaggerating edges.

- For plastic bumpers, step one grit finer at each stage (e.g., start 180 instead of 120) to avoid furrowing soft substrates.

Dialed-in grits give you the invisible slope you need and save you time later when primer sands effortlessly instead of fighting buried scratches.

Tools, Blocks, and Backing That Keep Edges Invisible

Your blocks and backing control the shape; your hands simply steer. Choose blocks that match the panel’s geometry and maintain contact across the bevel without digging. For feather edging, I keep three categories nearby:

- Rigid/long blocks (11–16 inches): Perfect for doors, hoods, and quarter panels. They flatten and stretch the bevel so the transition is longer and gentler. Great for initial shaping with 120–180 grit.

- Medium-density, flexible blocks: Conform to mild curves without rolling over the edge. Use them in the 180–320 range to refine without creating ripples.

- Soft foam or interface-backed pads: Ideal for delicate final passes (320–600), especially on crowns and complex shapes.

A DA sander is fine—strategically. Avoid using a DA with coarse grits right up to an edge; the rotation can chew a hollow or burn a sharp “lip.” Instead, let the block do the edge work, then feather the surrounding area with the DA on low speed with a 3–6 mm orbit and an interface pad to smooth the transition.

Backing matters as much as grit. A thin, semi-firm interface behind your paper spreads pressure so you’re cutting a wide slope, not a trench. On tight radiuses, swap to a thinner pad or a smaller block to keep your face flat to the panel.

Dust control helps you see. Hook up extraction when you can, or at least brush and blow off between passes. Clogged paper will make you press harder, which polishes highs and digs lows.

Work in straight, overlapping strokes; avoid tiny circles with a block. Think long, even passes across and beyond the edge, not on top of it. If you stay centered over the chip, you’ll cut a crater. Instead, park your block so only a third of it overlaps the edge and sweep through in both directions to lengthen the bevel.

According to a article, feathering is about distributing that transition over distance—great validation for building a longer taper rather than trying to hide a short step with thick primer.

Pro tips:

- Use a pencil line around the damage. Sand until the line disappears evenly; it’s a quick visual for edge roll.

- Keep a “clean hand.” Always feel the surface with a glove-free fingertip; dust can trick your eyes but not your skin.

- If you shave through to metal on the outer slope, stop, spot epoxy, and continue once cured—don’t fill that with polyester putty alone.

Feather‑Edging Workflow: Step‑By‑Step

Here’s a repeatable process you can run on anything from rock chips to bigger blend zones.

- Map and degrease

- Wash the panel and wax/grease remove. Outline defects with a pencil. Mark the intended feather zone, typically 1–3 inches beyond the damage.

- Initial cut and edge softening

- With 120–150 grit on a medium-firm block, sand from the outside in, crossing the edge to stretch the bevel. Keep your strokes long. Don’t camp on the center of the chip.

- Dust on guide coat, crosshatch, and repeat until the cliff edge is gone and a gentle taper appears.

- Refine the bevel

- Move to 180 grit. Sand at a 45-degree crosshatch, reapply guide coat, and ensure there are no deep 120 scratches left. Feel with eyes closed; you should barely detect a transition.

- Fill (if needed)

- If there’s a low, mix filler or glazing putty. Spread thinly, extending just beyond the low so you don’t build another hard edge.

- Shape filler with 120, refine with 180–220. Keep the slope long; don’t make a sharp filler ledge.

- Pre-primer finishing

- Sand the total blend zone with 220–240, then 320. Avoid over-polishing; a lightly abraded surface promotes primer adhesion.

- For larger areas, feather the surrounding paint with a DA at 320 with an interface pad just to unify texture.

- Seal and prime

- If bare metal is exposed, seal with epoxy. Once cured, apply 2–4 coats of 2K primer surfacer, extending beyond the feather edge.

- Dry guide coat the primer and block with 320–400; finish at 500–600 for basecoat.

- Inspect under light

- Use raking light and a tack rag. If you can’t feel or see the edge and the guide coat clears evenly, you’re ready for color.

Edge-control techniques:

- Keep the block bridging the edge, not sitting entirely on either side.

- Reduce pressure as you move to finer grits; let the paper refine the taper instead of cutting new shape.

- Rotate your stance and block angle often; this averages out your pressure and prevents channels.

When to stop:

- If you’re chasing a ghost line and the bevel is already 2–3 inches, primer and block-sanding will finish the job. Don’t keep thinning good OEM material; build it back with surfacer and sand it flat.

Avoiding and Fixing Edge Lines

Even experienced techs see the occasional halo after primer or paint. Here’s how to prevent and correct the most common culprits.

Causes and cures:

- Too-short bevel: If your transition is less than an inch around a chip, extend it. Go back to 180, stretch the slope to 2 inches, re-refine to 320, then reprime.

- Skipped grit scratches: If you see narrow, linear scratches after primer, you likely jumped a step. Guide coat, re-block with the missing grit, and step back up. Under base/clear, you may need to spot sand and re-prime.

- Edge swell: Solvent or moisture can swell edges, especially on old repaints. Allow adequate flash times, use epoxy sealer over sensitive edges, and avoid soaking wet-sanding before primer is fully cured.

- DA edge-bite: If the DA creates a divot at the edge, block it out. Use a firmer backing, lower DA speed, and keep the interface pad installed for grits over 220.

Actionable tips:

- Aim for a bevel at least the width of your block’s half-length. If you’re using a 6-inch block, don’t be shy about a 2–3 inch feather.

- Always guide coat primer and paint-edge transitions. If any specks of guide coat remain after a pass, don’t advance grits yet.

- For crowned panels, switch to a slightly narrower block and roll your wrists to keep full-face contact without tipping an edge.

- On plastics, preheat the part slightly with ambient shop warmth (not a heat gun) to normalize flexibility; cold plastics are easier to gouge.

Fixing a painted-in ghost:

- If a ring appears after color, allow the coating to cure, then wet sand the area with 1500–2000, reapply a blending coat or an extra clear pass that extends farther than the original edge, and polish. If the step is physical, you’ll still need to address it in primer—don’t expect clear alone to hide a ridge.

Work patiently here. Edges are where paint jobs are won or lost, and nothing beats a clean, invisible transition that stays invisible six months later.

The Best Sanding — Video Guide

This short video breaks down different sanding block styles used in restoration and repair, showing how flexibility, length, and face shape influence your results. You’ll see why a long, rigid block flattens panels and stretches bevels, while softer or curved options conform to crowns and complex contours without digging.

Video source: The Best Sanding Blocks for Autobody and Restoration

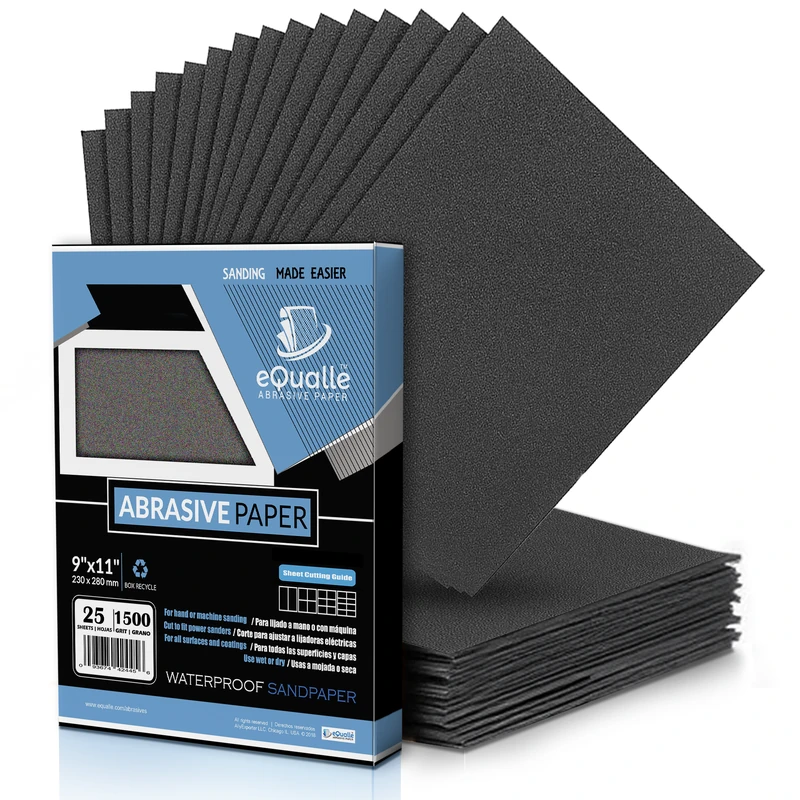

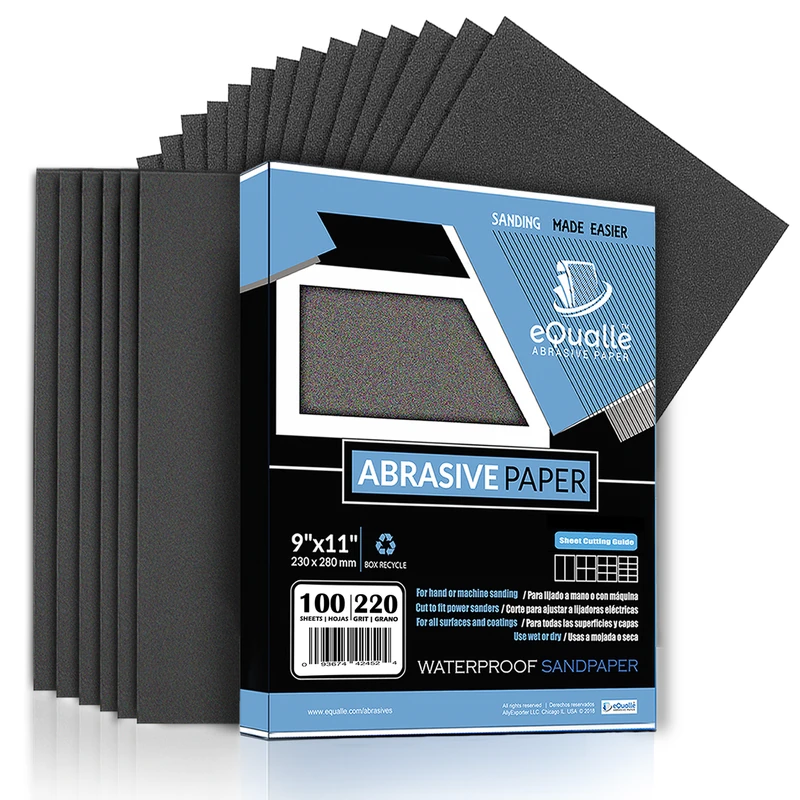

80 Grit Sandpaper Sheets (50-pack) — 9x11 in Silicon Carbide Abrasive for Wet or Dry Use — Durable coarse abrasive that evens out irregular surfaces and clears old coatings. Ideal for early sanding stages in woodworking, fiberglass, or metal preparation. (Professional Grade).

Frequently Asked Questions (FAQ)

Q: What grit should I start with to feather edge old paint?

A: For most chips and edges, begin with 120–150 grit on a medium-firm block to soften the cliff without gouging. Move to 180, then 220–240, and finish the pre-primer stage at 320. Only start coarser (100–120) if the old coating is very hard or thick.

Q: How far should I extend the feather around a repair?

A: Plan for 1–3 inches around small defects, more on larger blends. If you can still feel the edge with eyes closed, the bevel is too short. Extend until the transition disappears to the touch, then refine the entire zone evenly.

Q: Should I wet sand or dry sand when feather edging?

A: Dry sand for the beveling stages—guide coat is easier to read, and you won’t soften edges with moisture. After primer surfacer cures, you can dry block 320–400, then wet sand 500–600 before base if desired.

Q: What if I sand through to bare metal on the slope?

A: Stop, spot with epoxy primer to seal and stabilize the edge, then continue your feathering and primer build after the epoxy cures. Avoid relying on polyester putty alone over bare metal.

Q: How do I know I removed the previous grit’s scratches?

A: Use a dry guide coat and change your sanding direction 45–90 degrees with each grit. When the earlier scratch pattern disappears entirely and the guide coat clears uniformly, you’ve fully replaced it.